Preparation method of PEDOT/PSS dispersion liquid and preparation method of high pressure solid capacitor

A technology of dispersion liquid and reaction liquid, which is applied in the direction of solid electrolytic capacitors, capacitor parts, capacitor electrolyte/absorbent, etc., and can solve problems such as inapplicability, high concentration viscosity, poor film formation and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

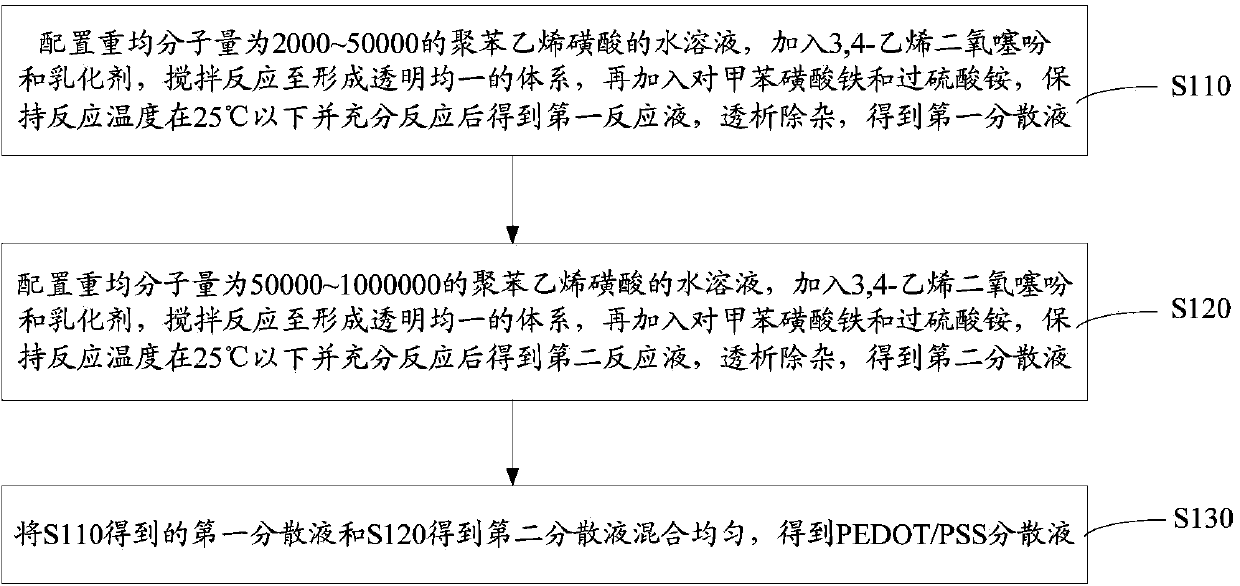

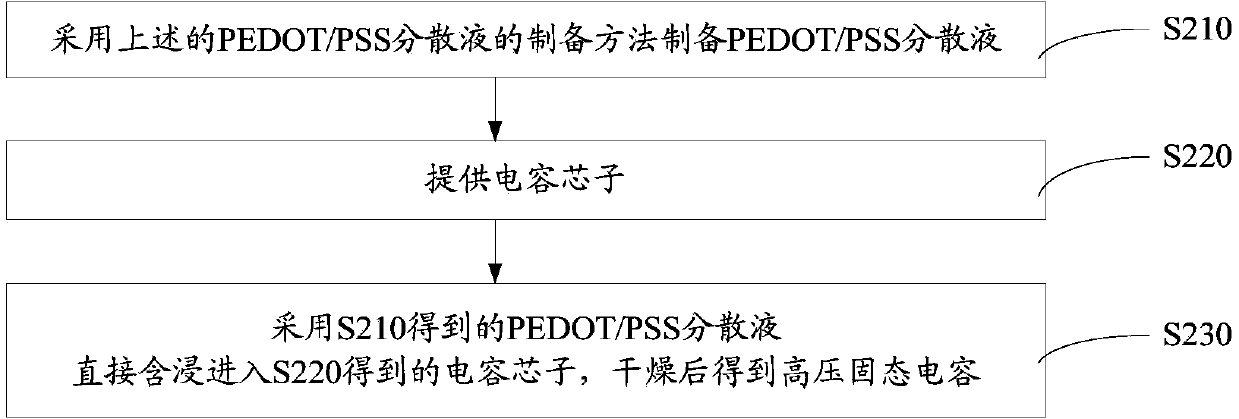

[0024] Such as figure 1 The preparation method of the PEDOT / PSS dispersion liquid of one embodiment shown, comprises the steps:

[0025] S110. Prepare an aqueous solution of polystyrene sulfonic acid with a weight-average molecular weight of 2,000 to 50,000, add 3,4-ethylenedioxythiophene and an emulsifier, stir and react until a transparent and uniform system is formed, then add iron p-toluenesulfonate and ammonium sulfate, keeping the reaction temperature below 25°C and fully reacting to obtain the first reaction liquid, which is dialyzed to remove impurities to obtain the first dispersion liquid.

[0026] Preferably, in S110, the weight average molecular weight of polystyrene sulfonic acid is 5000-20000.

[0027] Preferably, the mass ratio of polystyrenesulfonic acid with a weight average molecular weight of 2000-50000, 3,4-ethylenedioxythiophene and emulsifier is 30:10:5.

[0028] Preferably, the mass ratio of 3,4-ethylenedioxythiophene, ferric toluenesulfonate and ammon...

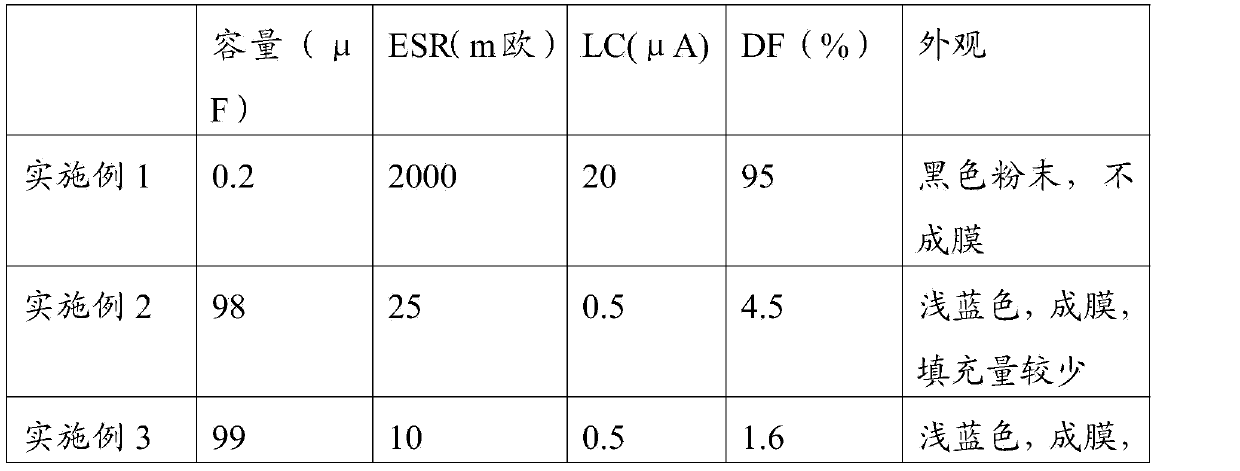

Embodiment 1

[0049] Take 1000mL of polystyrene sulfonic acid aqueous solution with a weight average molecular weight of 5000 and a solid content of 3%, put it in a 2L flask, add 10 grams of EDOT, and add 5 grams of emulsifier, stir, so that EDOT is completely emulsified and dispersed in water to form a transparent Uniform water dispersion, EDOT forms an oil-in-water emulsion in water, the particle size is less than 100nm, and the appearance is transparent. 100 mg of iron p-toluenesulfonate and 20 g of ammonium persulfate were prepared into 100 mL of aqueous solution, and slowly added dropwise to the reaction system. The reaction system gradually turns blue, keep the reaction temperature below 25 degrees, and react for 24 hours. After the reaction is completed, use the dialysis method, put it into a dialysis bag, repeatedly dilute the dialysis with pure water, and remove the residual unreacted monomer impurities and salt in the system by osmosis. Control the sodium ion concentration <50PPM...

Embodiment 2

[0052] Take 1000 mL of polystyrene sulfonic acid aqueous solution with a weight average molecular weight of 200,000 and a solid content of 2%, put it in a 2L flask, add 10 grams of EDOT, and add 5 grams of emulsifier, stir, so that EDOT is completely emulsified and dispersed in water to form Transparent and uniform water dispersion, EDOT forms an oil-in-water emulsion in water, the particle size is less than 100nm, and the appearance is transparent. 100 mg of iron p-toluenesulfonate and 20 g of ammonium persulfate were prepared into 100 mL of aqueous solution, and slowly added dropwise to the reaction system. The reaction system gradually turns blue, keep the reaction temperature below 25 degrees, and react for 24 hours. After the reaction is completed, use the dialysis method, put it into a dialysis bag, repeatedly dilute the dialysis with pure water, and remove the residual unreacted monomer impurities and salt in the system by osmosis. Control the sodium ion concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com