Wear-resistant epoxy resin/carbon fiber composite coating and its preparation and coating method

A technology of epoxy resin and composite coating, which is applied in the direction of epoxy resin coating, coating, and devices for coating liquid on the surface, etc., which can solve the problems that the performance of composite materials cannot be fully utilized, the shear strength of composite materials is low, and Poor mechanical properties and other problems, to achieve the effect of reducing direct interaction, excellent mechanical properties, and improving load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

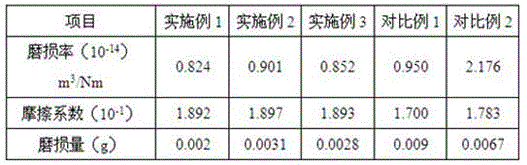

Examples

Embodiment 1

[0023] The wear-resistant epoxy resin / carbon fiber composite coating is formed by placing carbon fiber fabrics in a matrix solution for curing, wherein the raw materials of the matrix solution are: 65.5 parts by weight of epoxy resin, 32 parts by weight of polyamide resin, volume and ring The ratio of the total weight of the oxygen resin is 2.4mL: 1g of methyl ethyl ketone solution, the ratio of the volume to the total weight of the polyamide resin is 2.4mL: 1g of toluene solution, modified nano-TiO 2 0.5 parts by weight and 2 parts by weight of modified nano-montmorillonite.

[0024] The method for preparing an anti-wear epoxy resin / carbon fiber composite coating comprises the following steps: step 1, mixing bisphenol A type epoxy resin and bisphenol F type epoxy resin according to a volume ratio of 1:3 to prepare a ring Oxygen resin mixed solution, for subsequent use;

[0025] Step 2, take nano-TiO by said parts by weight 2 and with nano TiO 2With the same weight of coupl...

Embodiment 2

[0034] The wear-resistant epoxy resin / carbon fiber composite coating is formed by placing carbon fiber fabrics in a matrix solution for curing. The raw materials of the matrix solution are: 66.5 parts by weight of epoxy resin, 32 parts by weight of polyamide resin, volume and ring The ratio of the total weight of the oxygen resin is 2.4mL: 1g of methyl ethyl ketone solution, the ratio of the volume to the total weight of the polyamide resin is 2.4mL: 1g of toluene solution, modified nano-TiO 2 0.3 parts by weight and 1.2 parts by weight of modified nano-montmorillonite.

[0035] The preparation and coating method of the anti-wear epoxy resin / carbon fiber composite coating refer to Example 1.

Embodiment 3

[0037] The wear-resistant epoxy resin / carbon fiber composite coating is formed by placing carbon fiber fabrics in a matrix solution for curing. The raw materials of the matrix solution are: 64.5 parts by weight of epoxy resin, 33.5 parts by weight of polyamide resin, volume and ring The ratio of the total weight of the oxygen resin is 2.4mL: 1g of methyl ethyl ketone solution, the ratio of the volume to the total weight of the polyamide resin is 2.4mL: 1g of toluene solution, modified nano-TiO 2 0.4 parts by weight and 1.6 parts by weight of modified nano-montmorillonite.

[0038] The preparation and coating method of the anti-wear epoxy resin / carbon fiber composite coating refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com