Liquid cooling system for computer chip

A heat dissipation system and computer technology, applied in computing, instruments, electrical digital data processing, etc., can solve the problems of high flow pipeline requirements, overheating and burning of devices, and high price, and achieve the expansion of heat dissipation surface, low noise of working medium, and wide application area wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

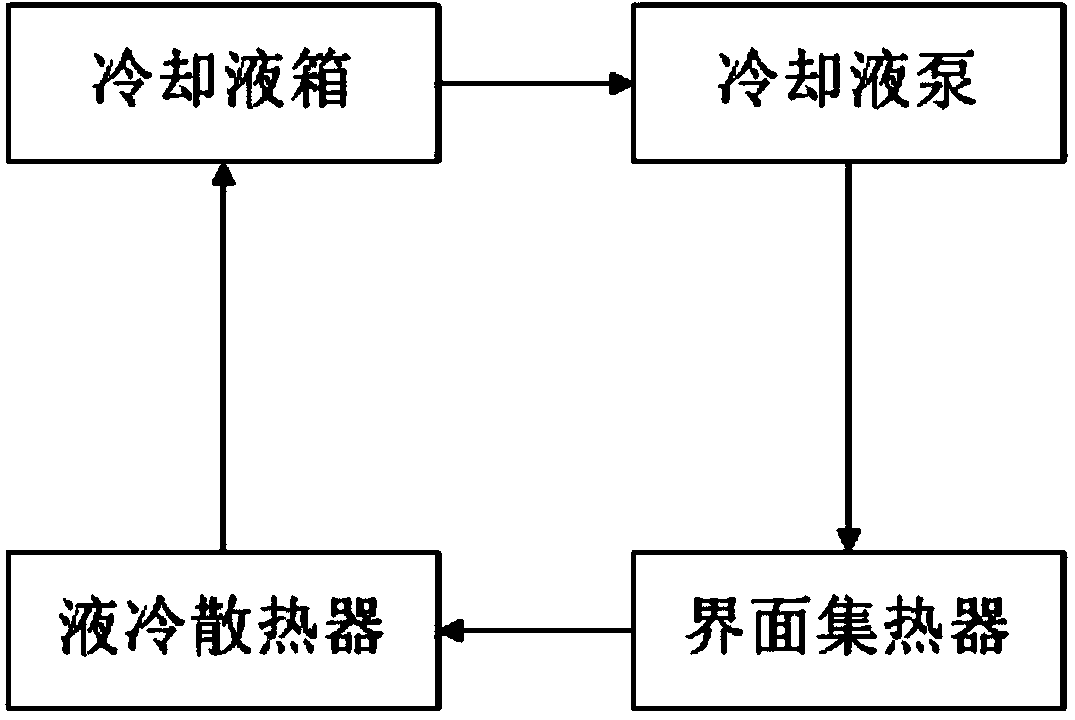

[0026] Such as figure 1 Shown is a structure diagram of a liquid cooling system based on the present invention. The system includes a coolant pump, an interface heat collector (cold head), a liquid-cooled radiator, and a coolant tank. The arrow lines in the figure indicate the liquid pipes that connect the above components. The coolant tank is used to store coolant, and driven by the coolant pump, the coolant circulates in the system along the direction of the arrow in the figure. The cooling pump preferably adopts a double-cavity parallel piezoelectric pump or an electrostatically driven silent pump. The interface heat collector is in direct contact with objects that need to be cooled, such as CPU, motherboard, memory, graphics card, and so on. The shape and size of the interface heat collector and the fixing method match the object that needs to be cooled. For example, for the CPU, the shape and size of the corresponding CPU cold head need to match the chip area of the C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com