A kind of method for preparing high nitrogen-doped nitrogen-doped graphene

A technology of nitrogen-doped graphene and graphene, which is applied in the field of nitrogen-doped graphene, can solve the problems of harsh preparation conditions, low doping amount, and high production cost, and achieve simple reactant components, low environmental pollution, and production equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

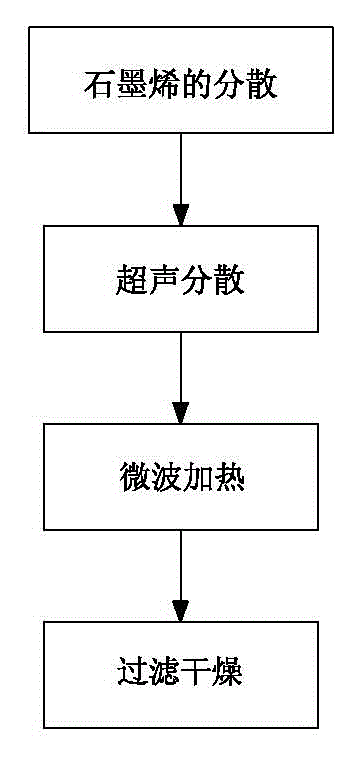

Image

Examples

Embodiment 1

[0022] (1) Dispersion of graphene: Prepare a graphene dispersion liquid with a concentration of 1.0 mg / mL, the dispersant is multilayer graphene, and the dispersant is deionized water.

[0023] (2) Ultrasonic dispersion: the graphene dispersion and nitrogen source were mixed at a certain mass ratio of 1:0.1, and after ultrasonic treatment for 2 hours, a mixture A was obtained, and the nitrogen source was polypyrrole, polyaniline and polypyridine.

[0024] (3) Microwave heating: move mixture A to a high-pressure reactor with a pressure of 50MPa, then place the reactor in a microwave oven with a power of 2000w, and heat for 600s to obtain mixture B.

[0025] (4) Filtration and drying: The mixture B was filtered through a 0.2 μm PTFE membrane filter, and the obtained filter cake was dried at a temperature of 80°C for 200 minutes to obtain nitrogen-doped graphene, and its nitrogen doping amount is shown in Table 1.

Embodiment 2

[0027] (1) Dispersion of graphene: Prepare a graphene dispersion liquid with a concentration of 2.0 mg / mL, the dispersant is bilayer graphene, and the dispersant is dehydrated alcohol.

[0028] (2) Ultrasonic dispersion: the graphene dispersion liquid and nitrogen source were mixed at a certain mass ratio of 1:3, and after ultrasonic treatment for 0.5, a mixture A was obtained, and the nitrogen source was triethylenetetramine.

[0029] (3) Microwave heating: move mixture A to a high-pressure reactor with a pressure of 1 MPa, then place the reactor in a microwave oven with a power of 1500w, and heat for 10 seconds to obtain mixture B.

[0030] (4) Filtration and drying: The mixture B was filtered through a 0.2 μm PTFE membrane filter, and the obtained filter cake was dried at a temperature of 150°C for 20 minutes to obtain nitrogen-doped graphene, and the nitrogen doping amount is shown in Table 1.

Embodiment 3

[0032] (1) Dispersion of graphene: Prepare a graphene dispersion liquid with a concentration of 3.0 mg / mL, the dispersant is multilayer graphene, and the dispersant is acetone.

[0033] (2) Ultrasonic dispersion: the graphene dispersion and nitrogen source were mixed at a certain mass ratio of 1:10, and after ultrasonic treatment for 0.8 h, a mixture A was obtained, and the nitrogen source was melamine and dopamine.

[0034] (3) Microwave heating: move mixture A to a high-pressure reactor with a pressure of 5 MPa, then place the reactor in a microwave oven with a power of 600w, and heat for 600s to obtain mixture B.

[0035] (4) Filtration and drying: The mixture B was filtered through a 0.2 μm PTFE membrane filter, and the obtained filter cake was dried at a temperature of 100°C for 80 minutes to obtain nitrogen-doped graphene, and the nitrogen doping amount is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com