Self-cleaning glass and preparation method thereof

A self-cleaning and glass technology, applied in the field of self-cleaning glass and its preparation, can solve the problems of poor bonding force of glass substrates, small specific surface area, affecting the durability of the film layer, etc., and achieve high light transmittance and high light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

[0053] Step (1): Using glass (float glass, with a light transmittance of 90%) as the substrate, a titanium film was prepared on the glass substrate by the medium-frequency pulse magnetron sputtering method, and the titanium target was installed on the medium-frequency pulse cathode with a frequency of 75KHz~125KHz, the duty cycle is 2.5μs~4μs, and the intermediate frequency bias voltage of -10V~-40V is applied. The glass substrate is installed on the workbench, and the temperature of the workbench is 200°C-400°C, that is, the deposition temperature is 200°C-400°C. Introduce argon gas, adjust the chamber pressure (that is, the deposition pressure) to 0.1Pa~0.5Pa, sputter the titanium target, and the power density of the titanium target is 4.0w / cm 2 ~5.5w / cm 2 , the thickness of the deposited titanium film is 1.5 μm;

[0054] Step (2): Perform anodic oxidation on the glass substrate after depositing the titanium film in step (1), use the glass substrate after depositing the ti...

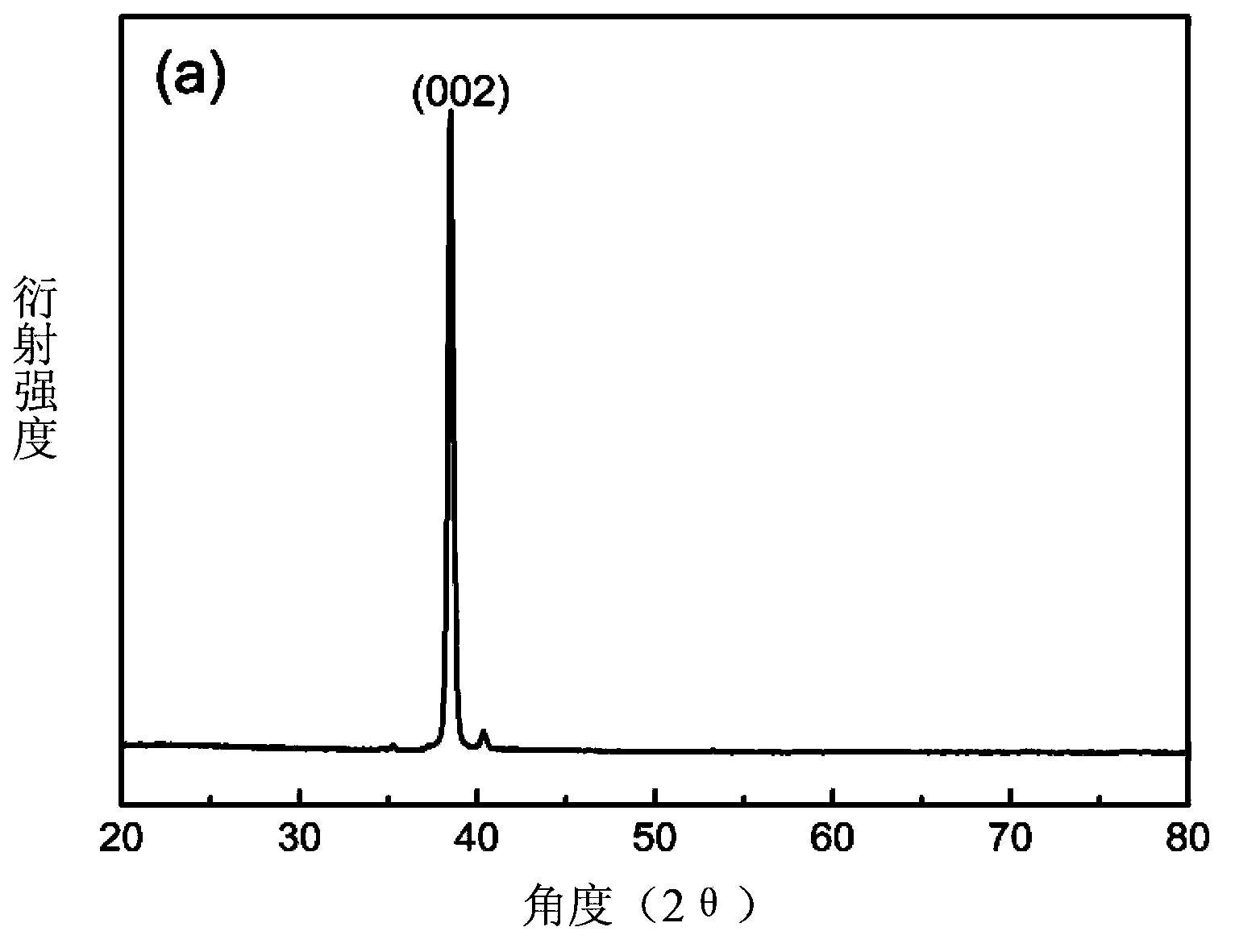

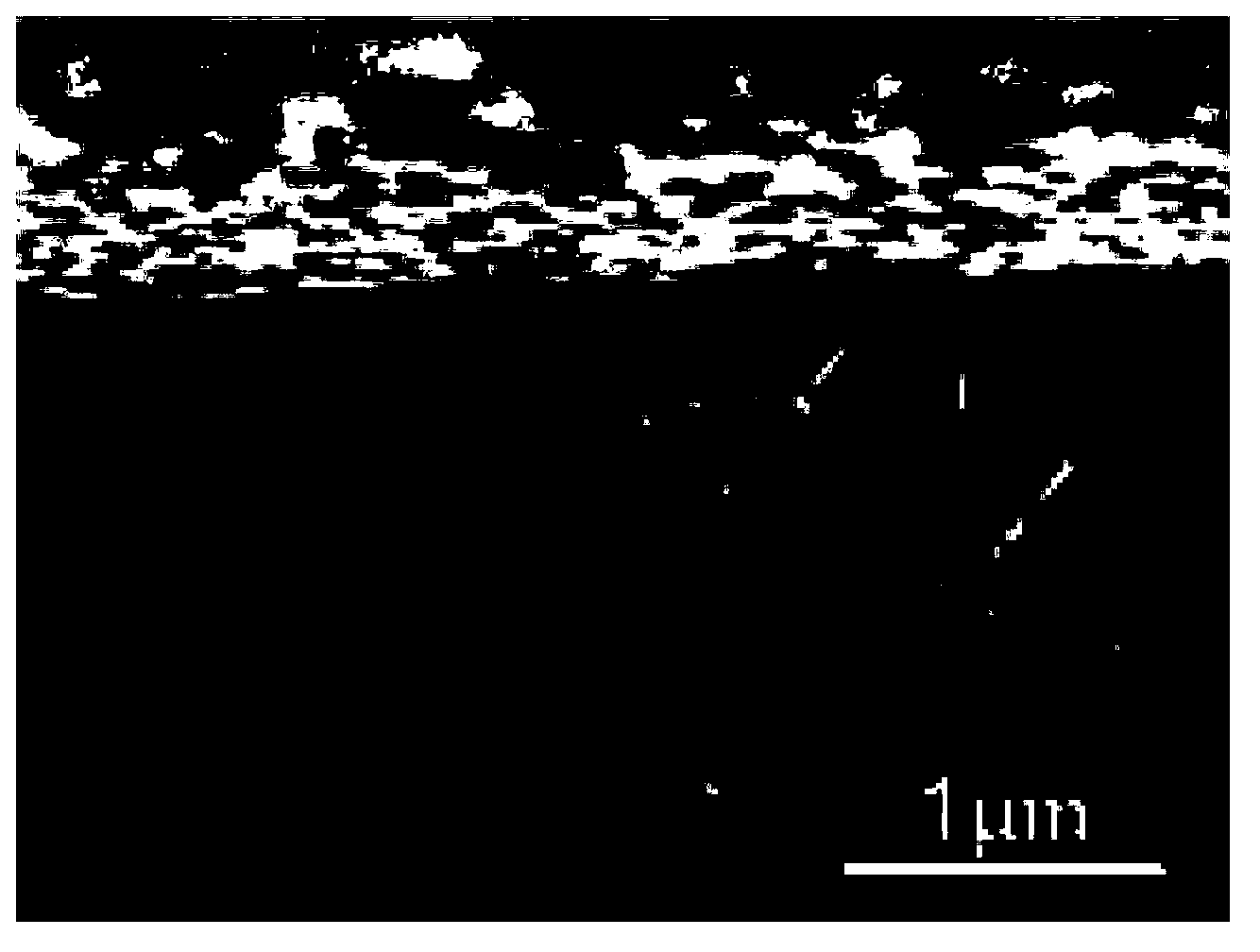

Embodiment 7

[0057] Example 7 The X-ray diffraction (XRD) spectrum of a titanium film deposited by magnetron sputtering on a glass substrate is as follows: figure 2 As shown, it can be seen that the titanium film grows along the (002) crystal plane, look up the PDF card (Ti44-1294JCPDS) for phase analysis, and it is a close-packed hexagonal structure. Example 7 A cross-sectional scanning electron microscope (SEM) photo of a titanium film deposited by magnetron sputtering on a glass substrate is shown in image 3 As shown, it can be seen that the cross-sectional structure of the titanium film is dense. Depend on figure 2 and image 3 It can be seen that the titanium film grows along the (002) crystal plane, and the film structure is dense. Table 3 shows the structures and physical properties of the titanium films deposited by magnetron sputtering on glass substrates in Examples 1-12. It can be seen from Table 3 that the crystal structure of the prepared titanium film mainly grows alon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com