Preparation method of man-made reservoir physical model, and special cementing agent for man-made reservoir physical model

A physical model and cementing agent technology, applied in the field of artificial reservoir physical model, can solve the problem that the real characteristics of natural reservoirs cannot be well simulated, the lattice structure of mineral raw materials is easily changed or destroyed, and the pH value of surfactant precipitation is increased. problems, to achieve the effects of scientific and reasonable composition, improved mechanical strength and stability, and suitable pressing pressure and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of a homogeneous artificial reservoir physical model for simulating the natural core of a certain reservoir in Daqing

[0035] 1. Determination of natural core composition and physical parameters

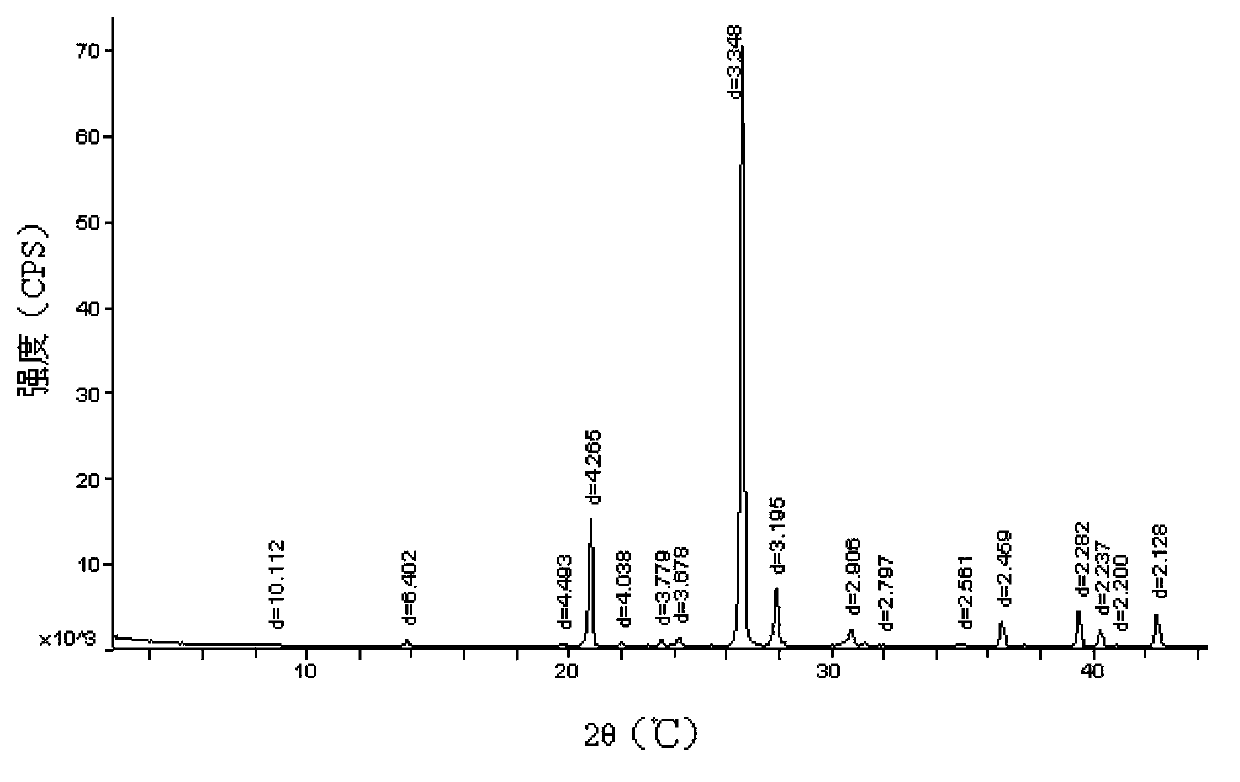

[0036] The natural core comes from Daqing Oilfield, XRD whole rock analysis is carried out on it by X-ray diffractometer, the XRD pattern is shown in figure 1 , and the corresponding composition results are shown in Table 1; the gas permeability, porosity and pore volume were measured by the method described in the SY / T5336-2006 industry standard, and the results are shown in Table 2.

[0037] 2. Preparation of a homogeneous artificial reservoir physical model

[0038] Add 450g of sodium fluorosilicate to 2.31kg of water glass, stir at room temperature until the sodium fluorosilicate is evenly dispersed, then add 240g of sodium aluminosilicate, stir at room temperature until the sodium aluminosilicate is evenly dispersed, and obtain 3kg of special ceme...

Embodiment 2

[0042] Example 2 Preparation of a homogeneous artificial reservoir physical model for simulating the natural core of a certain reservoir in Daqing

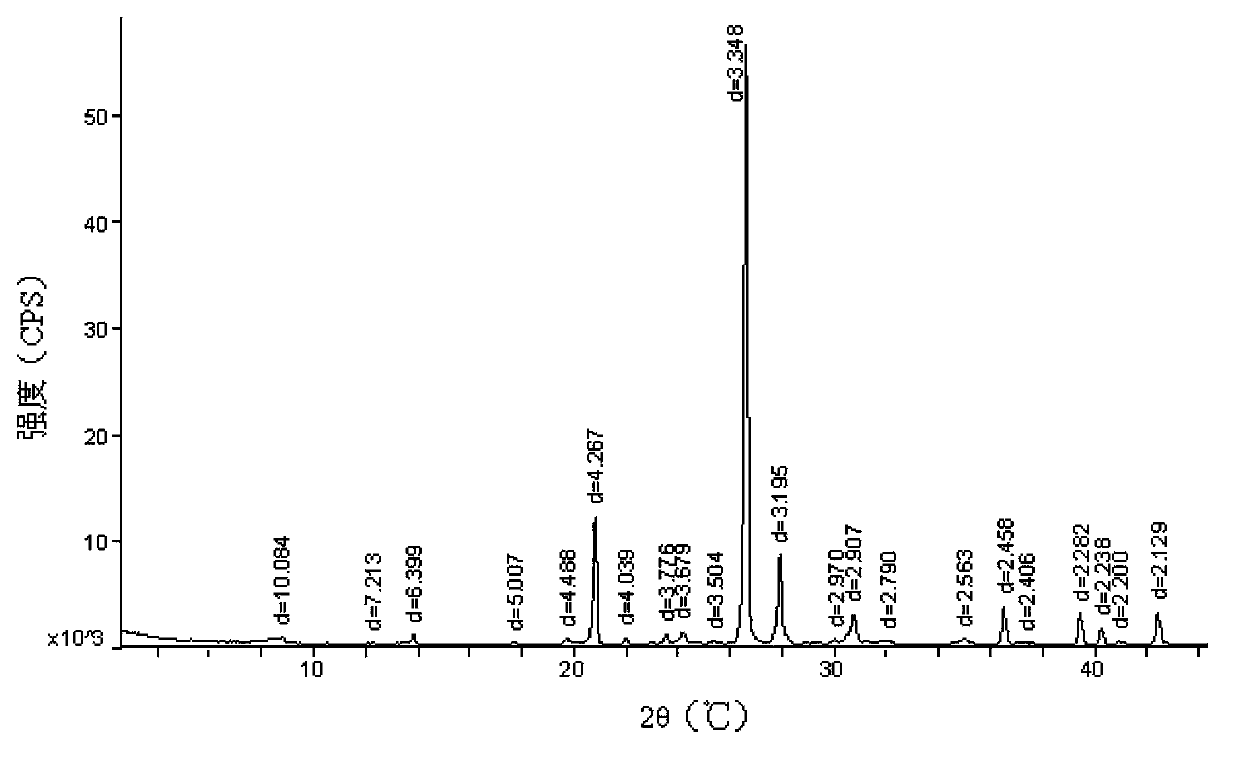

[0043] 1. Determination of natural core composition and physical parameters

[0044] The natural core comes from Daqing Oilfield, and its XRD pattern is shown in image 3 , the corresponding composition results are shown in Table 1, and the gas permeability, porosity and pore volume results are shown in Table 2.

[0045] 2. Preparation of a homogeneous artificial reservoir physical model

[0046] Add 540g of sodium fluorosilicate to 2.772kg of water glass, stir at room temperature until uniformly dispersed, then add 288g of sodium aluminosilicate, stir at room temperature until uniformly dispersed, and prepare a 3.6kg artificial reservoir physical model Cementing agent, wherein the mass content of each component is: water glass 77%, sodium fluorosilicate 15%, sodium aluminosilicate 8%.

[0047] According to the gas permeability...

Embodiment 3

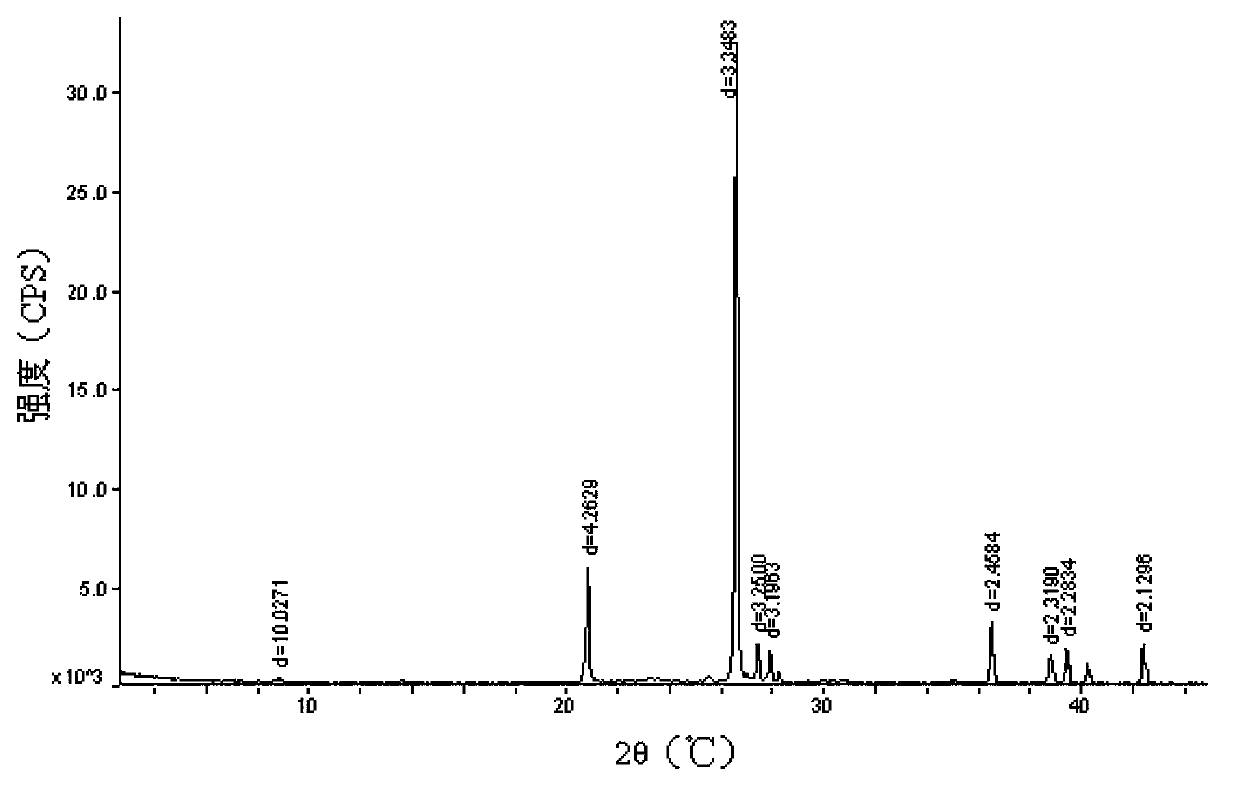

[0049] Example 3 Preparation of Heterogeneous Artificial Reservoir Physical Model

[0050] Add 429g of sodium fluorosilicate to 2.64kg of water glass, stir at room temperature until uniformly dispersed, then add 231g of sodium aluminosilicate, stir at room temperature until uniformly dispersed, and prepare a 3.3kg artificial reservoir physical model Cementing agent, wherein the mass content of each component is: water glass 80%, sodium fluorosilicate 13%, sodium aluminosilicate 7%.

[0051] According to the gas permeability requirement of 850mD, 5.09kg of quartz sand of 40-120 mesh, 185g of feldspar of 400-1000 mesh, 185g of clay mineral of 400-1000 mesh were respectively taken, and after mixing evenly, 5.46kg of hyperpermeable mineral raw materials were obtained (wherein The mass ratio of quartz sand, feldspar and clay minerals is 27.5:1:1);

[0052] According to the gas permeability requirement of 330mD, take 3.19kg of quartz sand of 20-100 mesh, 1.37kg of feldspar of 400-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com