Preparation method for trimethylolpropane tricarboxylate

A technology of trimethylolpropane tricarboxylate and trimethylolpropane, which is applied in the field of preparation of trimethylolpropane tricarboxylate, can solve problems such as not being environmentally friendly and not suitable for industrial production, and achieve good purity , protect the environment or safe production, easy to separate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

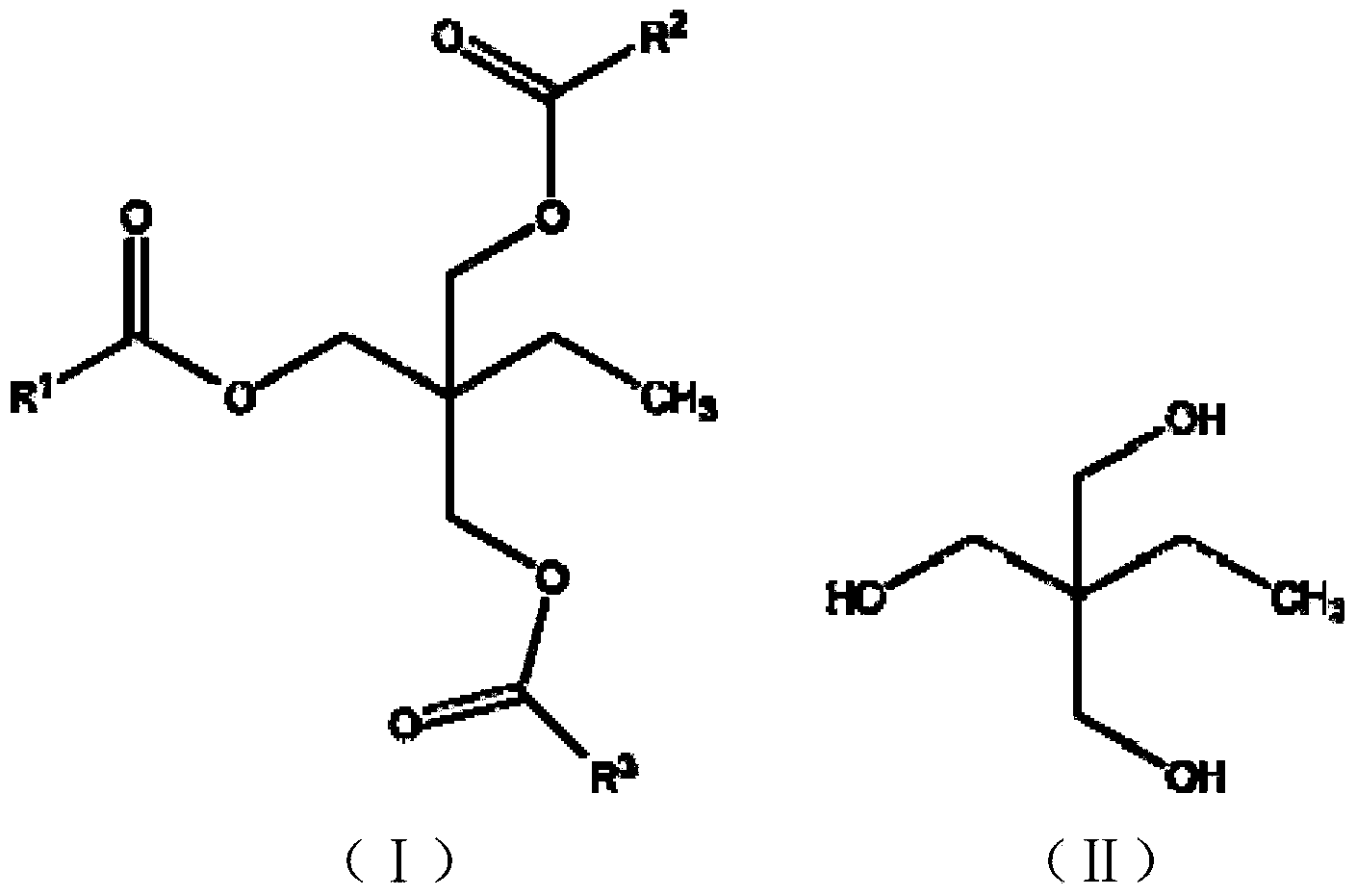

[0016] According to the preparation method of the present invention, when R 1 , R 2 , R 3 At the same time, carboxylate R 1 COOR, R 2 COOR, R 3 COOR means the same substance, hereinafter referred to as carboxylate R 1 COOR.

[0017] According to the preparation method of the present invention, only in the presence of a catalyst containing anhydrous potassium carbonate, the trimethylolpropane with the structural formula (II) and carboxylate R 1 The purpose of the present invention can be achieved when the transesterification reaction of COOR occurs, that is, it is beneficial to environmental protection, the product is easily separated from the reactant and the catalyst, and the yield is high and the purity is good. However, preferably, the transesterification reaction includes performing the reaction under distillation or rectification conditions (at this time, the distillation or rectification conditions are equivalent to the trimethylolpropane with the structural formul...

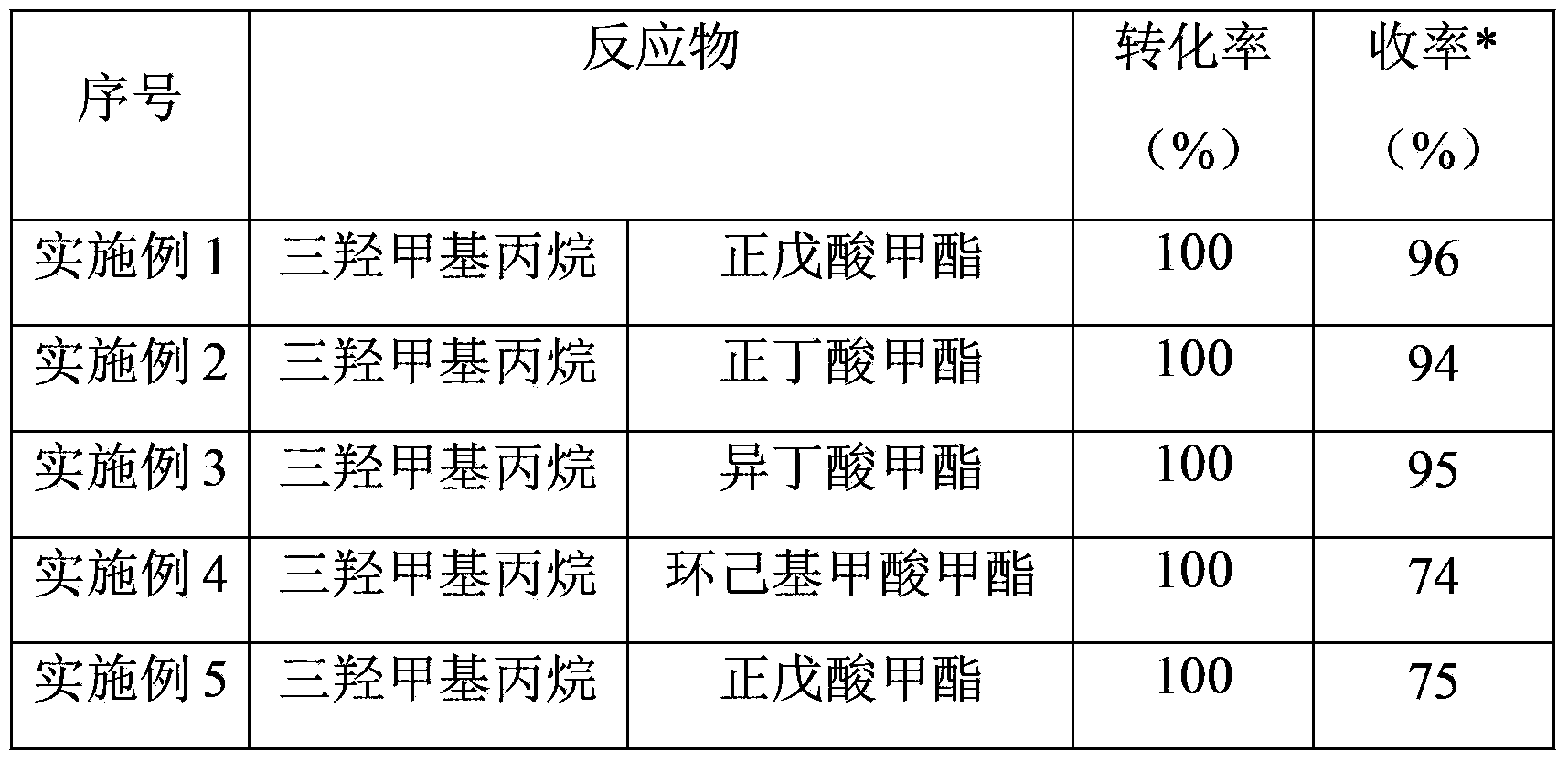

Embodiment 1

[0037] This embodiment is used to illustrate the preparation method of trimethylolpropane tripalate provided by the present invention.

[0038] Add 9.84g (0.075mol) trimethylolpropane (98%), 50.55g (0.44mol) methyl n-valerate, 2.01g (0.015 mol) anhydrous potassium carbonate, heat the oil bath in contact with the round bottom flask to 118°C, and react at 0.1MPa. During the reaction, distill the generated methanol to the liquid separator by distillation method and remove it. After reacting for 6 hours, transfer to Add toluene into the round-bottomed flask, add 6 times in total, the time interval between two adjacent additions is 1.5 hours, add 10mL each time, react for 1 hour after each addition of toluene, and distill toluene and azeotrope out of the round bottom at the same time The flask, after the reaction solution was cooled for about 30 minutes, added the next toluene. After the reaction, the mixture in the round bottom flask was cooled and filtered to remove anhydrous po...

Embodiment 2

[0040] This embodiment is used to illustrate the preparation method of trimethylolpropane tri-n-butyrate provided by the present invention.

[0041] Add 10.66g (0.08mol) trimethylolpropane (98%), 51.78g (0.50mol) methyl n-butyrate, 2.22g (0.016 mol) anhydrous potassium carbonate, heat the oil bath in contact with the round-bottomed flask to 98°C, and react at 0.1MPa. During the reaction, distill the generated alcohol to the liquid separator by distillation and remove it. After 6 hours of reaction, transfer to Add methyl n-butyrate into the round bottom flask, add 6 times in total, the time interval between two adjacent additions is 2 hours, add 10mL each time, add methyl n-butyrate each time and react in an oil bath at 100°C 1.5 hours and at the same time methyl n-butyrate and the azeotrope were distilled out of the round bottom flask, and the next methyl n-butyrate was added after the reaction liquid was cooled for about 30 minutes. After the reaction, the mixture in the rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com