Method for controlling palladium residue in fosaprepitant dimeglumine

A technology for fosaprepitant dimeglumine and palladium residues is applied in the field of controlling palladium residues in fosaprepitant dimeglumine, can solve problems such as unsatisfactory effects, and achieves good palladium removal effect and cheap raw materials Easy-to-obtain, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

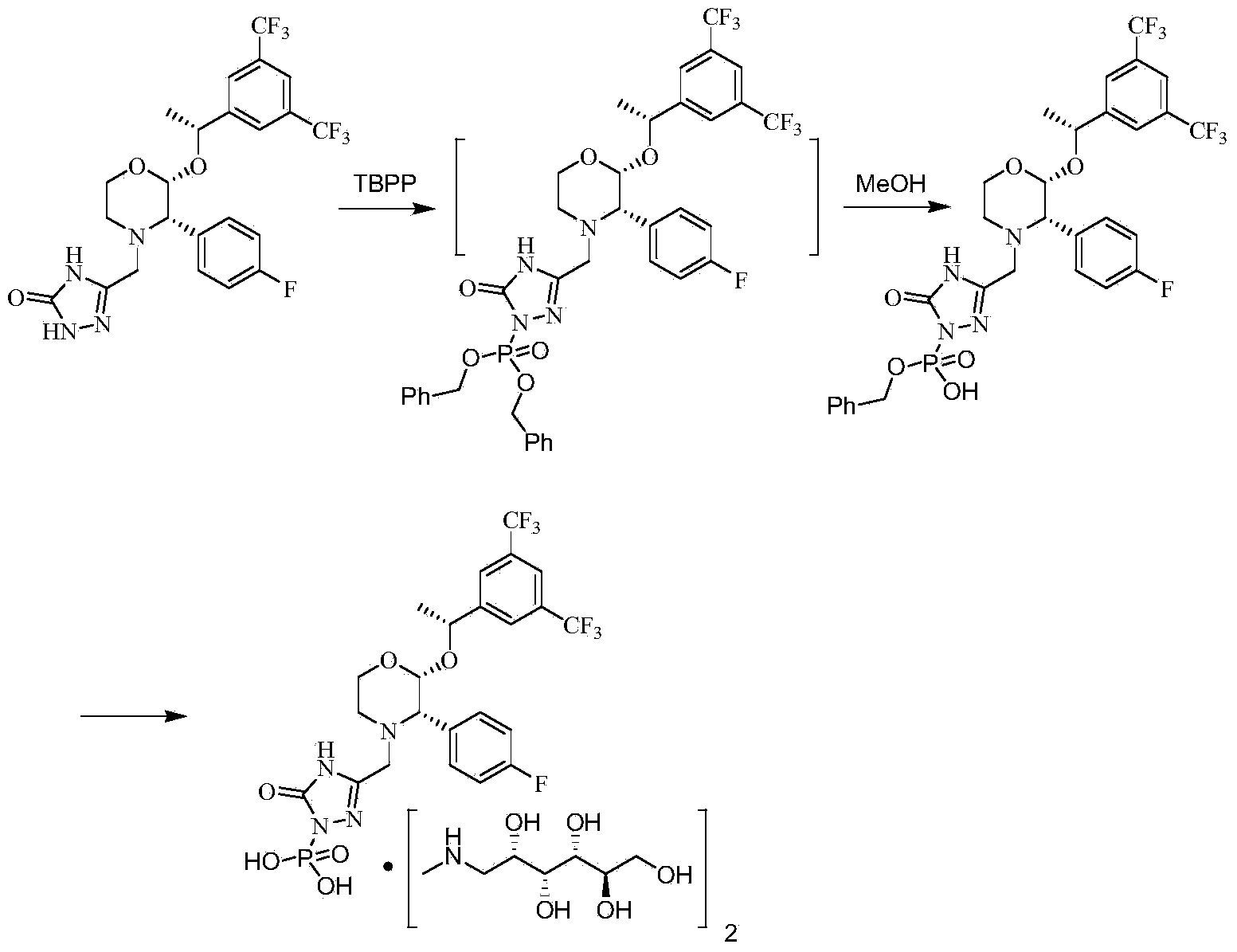

Method used

Image

Examples

Embodiment 1

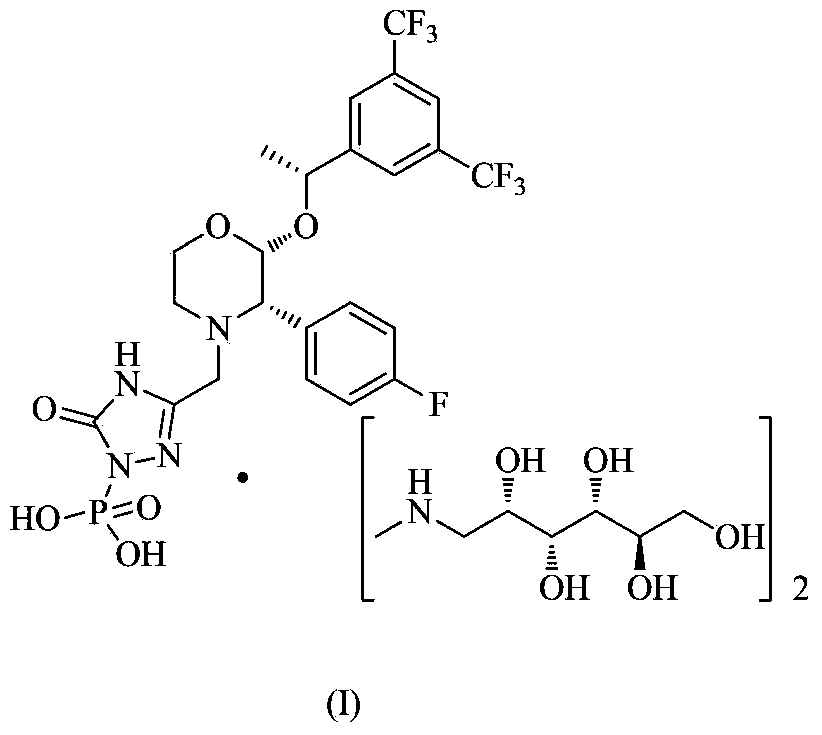

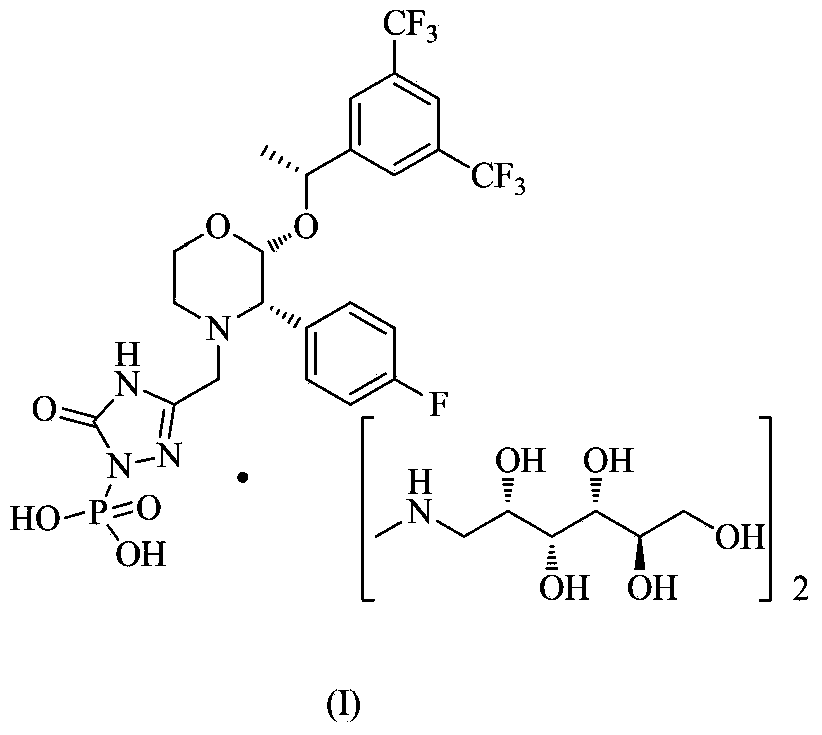

[0026] Example 1 Preparation of fosaprepitant dimeglumine

[0027] 19g intermediate [3-[[(2R,3S)-2-[(1R)-1-[3,5-bis(trifluoromethyl)phenyl]ethoxy]-3-(4-fluoro Phenyl)-4-morpholinyl]methyl]-2,5-dihydro-5-oxo-1H-1,2,4-triazol-1-yl]phosphonic acid monobenzyl ester (19g, 0.027 mol), meglumine (10.3g, 0.053mol), 1g of palladium on carbon, and 400mL of methanol were put into a hydrogenation kettle, and hydrogenated at 1.5-2.0MPa for 10 hours. After the reaction is finished, filter off Pd / C, concentrate the filtrate under reduced pressure to remove part of the solvent, slowly drop it into a mixed solvent of 200 mL of absolute ethanol and 200 mL of anhydrous acetonitrile, filter, and dry in vacuum to obtain Fosaprepitant Dimeglumine.

[0028] 1 HNMR (CD3OD, 500MHz, ppm) δ: 1.43 (d, J=6.6, 3H), 2.72 (s, 6H), 2.84 (d, J=13.8, 1H), 2.94 (d, J=10.3, 1H), 3.11-3.30(m, 4H), 3.42-3.82(m, 14H), 4.19-4.24(m, 3H), 4.35(d, J=2.2, 1H), 7.03(t, J=8.5, 2H), 7.34 (s, 2H), 7.51 (brs, 2H), 7.69 (s...

Embodiment 2

[0033] Dissolve 5 g of fosaprepitant dimeglumine in 20 mL of methanol, stir to dissolve, add 1 g of activated carbon at 25 ° C, stir for 1 h, filter, and drop the filtrate into a mixed solvent of 40 mL of absolute ethanol and 40 mL of anhydrous acetonitrile, Filter and vacuum-dry to obtain a sample of fosaprepitant dimeglumine.

[0034] Get an appropriate amount of fosaprepitant dimeglumine I to measure the residual palladium, and with reference to the detection method of Example 1, it is measured by atomic absorption spectrophotometry, and the residual palladium is 0.1ppm.

[0035] ESI-MS615 (M+H, 100%).

Embodiment 3

[0037] Dissolve 5g of fosaprepitant, pepitant dimeglumine in 20mL of methanol, stir to dissolve, add 1g of diatomaceous earth at 25°C, stir for 1h, filter, and drop the filtrate into a mixed solvent of 40mL of absolute ethanol and 40mL of anhydrous acetonitrile , filtered, and vacuum-dried to obtain a sample of fosaprepitant dimeglumine.

[0038] Take an appropriate amount of fosaprepitant dimeglumine I to determine the residual palladium, and determine by atomic absorption spectrophotometry with reference to the detection method of Example 1, the residual palladium is 0.08ppm.

[0039] ESI-MS615 (M+H, 100%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com