Oxa-phosphaphenanthrene fire retardant as well as preparation method and application of oxa-phosphaphenanthrene fire retardant

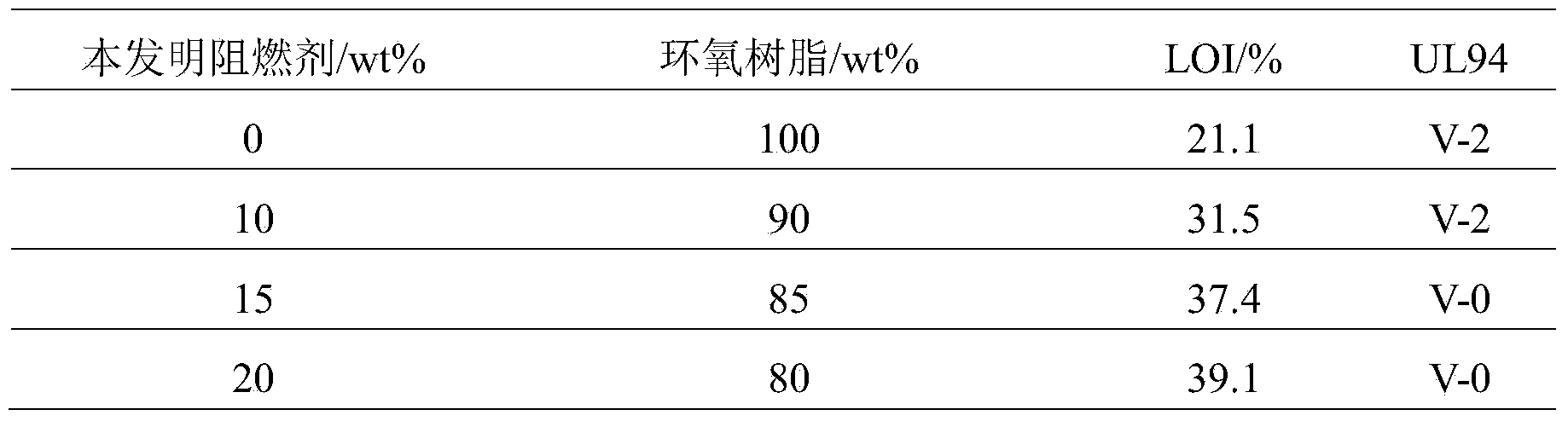

A technology of oxaphosphaphenanthrene and flame retardant, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as personal safety threats, application restrictions, and excessive smoke. Achieve the effects of good thermal stability, simple operation and high flame retardant rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

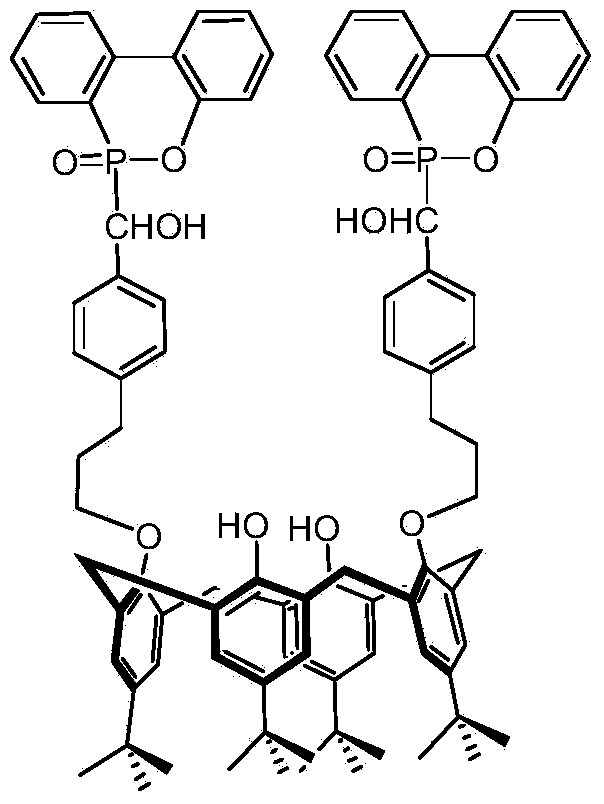

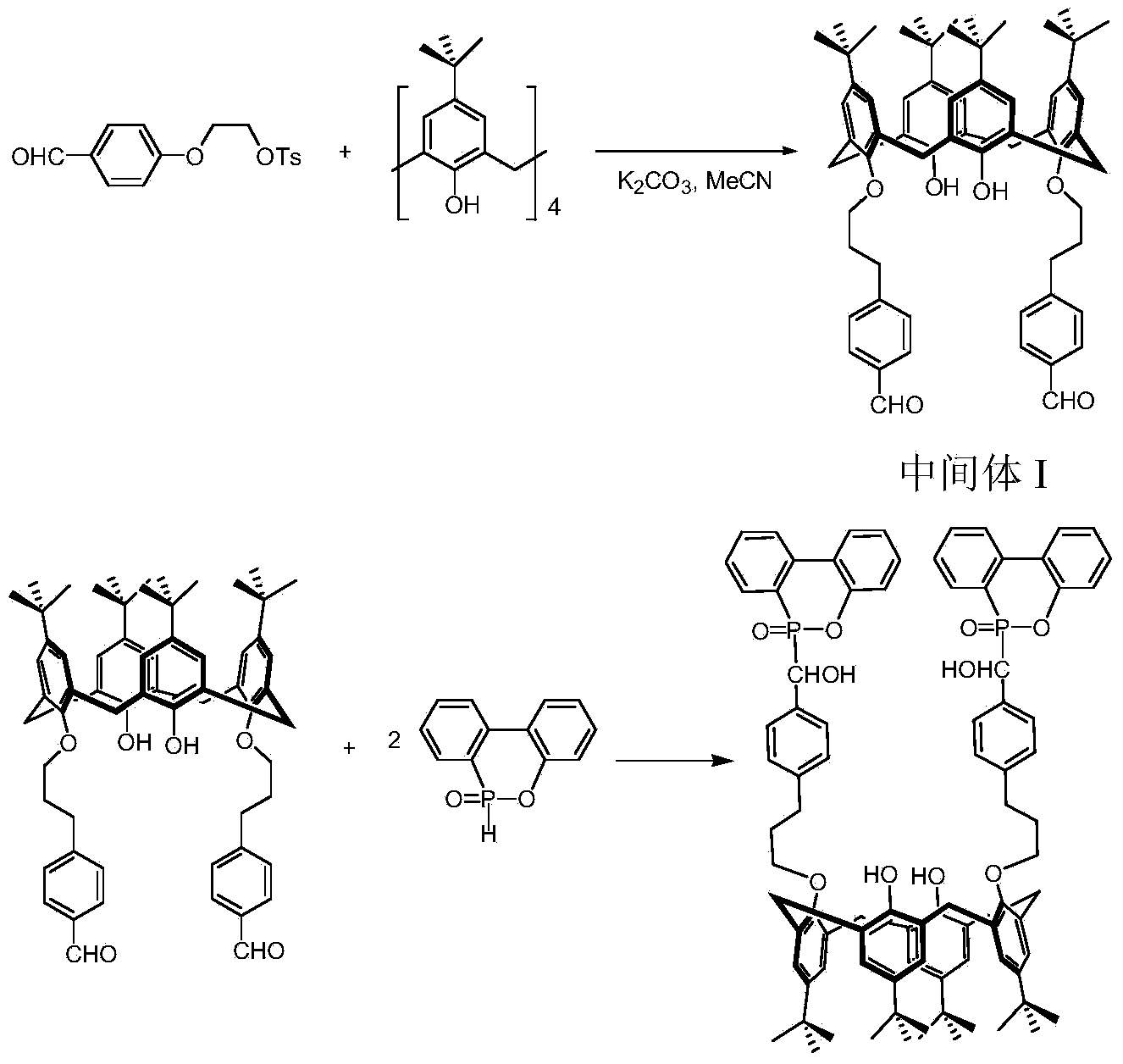

[0021] A preparation method of oxaphosphine phenanthrene flame retardant, the steps are:

[0022] Add p-tert-butylcalix[4]arene (2.96g, 4mmol), p-toluenesulfonate ethoxy-p-benzaldehyde (2.56g, 8mmol) and potassium carbonate (2.20g , 16mmol), stirred and refluxed for 45h, TLC detected that the basic reaction of the raw materials was complete, the solvent was evaporated under reduced pressure, the residue was extracted with hydrochloric acid and chloroform respectively, and the organic layer was washed with sodium bicarbonate solution. The organic layer was separated, dried over anhydrous magnesium sulfate, filtered, and concentrated to form a large amount of precipitates. An appropriate amount of chloroform-methanol mixed solvent was recrystallized to obtain Intermediate I (white solid), with a yield of 85.6%.

[0023] Intermediate I9.44g (10mmol) and DOPO4.32g (20mmol) were placed in a flask, and then 100mL of chloroform and 100mL of anhydrous methanol were added, and the reac...

Embodiment 2

[0030] Increase the p-toluenesulfonate group ethoxy-p-benzaldehyde to 2.62g (8.2mmol), and the others are the same as Example 1, and the yield of intermediate I is 86.8%.

Embodiment 3

[0032] Increase the p-toluenesulfonate group ethoxy p-benzaldehyde to 2.94g (9.2mmol), and the other is the same as Example 1, and the yield of intermediate I is 88.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com