gpes rigid foam composite plastic insulation board and manufacturing method thereof

A technology of composite plastic and rigid foam, which is applied in the field of rigid foam composite plastic insulation boards for heat insulation, can solve the problems of high cost and limited application range, and achieve uniformity of temperature field, increase of frictional resistance, and uniformity of temperature field best results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

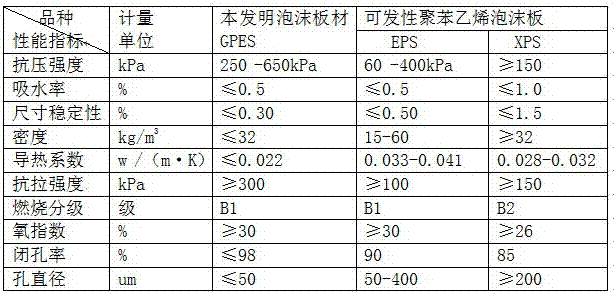

[0065] A GPES rigid foam composite plastic insulation board, which includes the following components by weight: 8 parts of modified nano-graphite particles, 5 parts of polyethylene (such as Yanshan Petrochemical 5200B), 85 parts of polystyrene (such as Yanshan Petrochemical 666D), 0.05 parts of glyceryl monostearate, 3.5 parts of supercritical carbon dioxide fluid. The supercritical carbon dioxide fluid is produced from waste gas, and then pressurized to 8MPa by a high-pressure pump. It is a canned liquid product produced by Qingdao Chengyang Changsong Gas Co., Ltd.

[0066] The nano-graphite particles that have been physically modified on the surface are compounded and mixed with 75 parts of nano-graphite powder graded from 0.8um-38um continuous particles and 25 parts of polyethylene, and are mixed at 150±5°C and 4MPa pressure by a single-screw mixer. Under certain conditions, extruded and cooled to produce round or cylindrical particles with a diameter of less than 2mm.

[...

Embodiment 2

[0097] The similarities between this example and Example 1 will not be repeated, and the difference lies in 92 parts of polystyrene, 3 parts of modified nano-graphite particles, and 3 parts of polyethylene.

[0098] The performance index of the foam board produced:

[0099] ⑴ Compressive strength: 265kPa.

[0100] (2) Water absorption rate: 0.62%.

[0101] ⑶ Dimensional stability: 0.7%.

[0102] ⑷ Density: 36.4kg / m 3 .

[0103] ⑸, closed cell rate: 92%;

[0104] ⑹. Thermal conductivity: 0.028 w / (m·K).

[0105] ⑺, combustion classification B1 level. Oxygen index: 30.2%

[0106] ⑻, tensile strength: 285kPa

[0107] ⑼. Water vapor permeability coefficient: 1.85 (ng / Pa.m.s).

[0108] When the amount of modified nano-graphite particles is less than 3 parts, the pressure at the extrusion port is less than 6 MPa, which does not meet the production requirements; when the weight part of polyethylene is 3 parts or less, the diameter of the bubbles of the thermal conductivity ex...

Embodiment 3

[0110] The similarities between this example and Example 1 will not be repeated, and the difference is 88 parts of polystyrene, 6 parts of modified nano-graphite particles, and 4 parts of polyethylene.

[0111] The performance index of the foam board produced:

[0112] ⑴ Compressive strength: 286kPa.

[0113] (2) Water absorption rate: 0.48%.

[0114] (3) Dimensional stability: 0.28%.

[0115] ⑷. Density: 31.9kg / m 3 .

[0116] ⑸, closed cell rate: 98%.

[0117] ⑹. Thermal conductivity: 0.022 w / (m·K).

[0118] ⑺, combustion classification B1 level. Oxygen index: 30.8%

[0119] (8) Tensile strength: 345 kPa.

[0120] ⑼. Water vapor moisture permeability coefficient: 1.79 (ng / Pa.m.s).

[0121] The properties of the above-mentioned foam board meet the requirements of the optimal index of the present invention, the dimensional stability, thermal conductivity, and water absorption all reach the optimal index, and the combustion performance also meets the requirements of B1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com