Method for preparing porous nanofiber

A nanofiber and nanoparticle technology, applied in the field of preparation of porous nanofibers, can solve the problems of poor hydrophilicity and dyeability, pollute the environment, complicated operation, etc., achieve the improvement of dyeing rate and color, protect the environment, and improve the specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

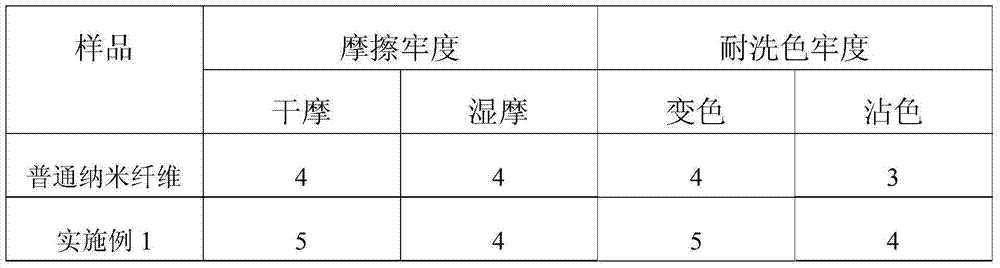

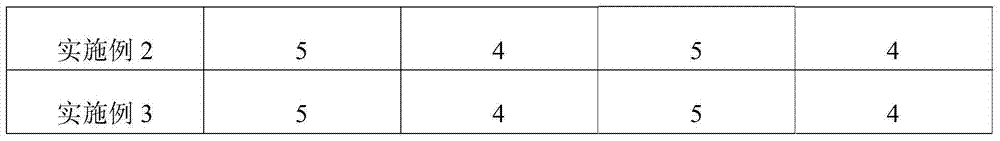

Examples

Embodiment 1

[0020] Dissolving the spinning material in a solvent, adding 10% polyvinylpyrrolidone, and stirring evenly, to prepare a nanofiber spinning solution; the mass ratio of the textile material to the solvent is 1:9, and the nanomaterials are polyester, polyacrylonitrile and One or more material mixtures in the copolymer and lignin, the solution is N,N-dimethyldiamide.

[0021] 5% SiO 2 Nanoparticles are added into the nanofiber polymer solution, stirred until uniform by magnetic force, and used as a spinneret solution.

[0022] Add the spinning solution to the electrospinning machine for electrospinning, the additional electric field strength is 0.2kv / cm, the distance between the receiving screen and the spinneret is 10cm, and the baking temperature is 400°C, and the SiO-containing 2 Nanoparticle fibers.

[0023] Will contain SiO 2 The nanofibers of the nanoparticles are soaked in 25% HF solution and stirred slowly for 8 hours, washed and dried to obtain a porous nanofiber fabr...

Embodiment 2

[0026] Dissolve the spinning material in the solvent, add 10% polyvinylpyrrolidone, stir well, and prepare the nanofiber spinning solution; the mass ratio of the textile material to the solvent is 1:5, and the nanomaterials are polyester, polyacrylonitrile and its One or more material mixtures in the copolymer and lignin, the solution is N,N-dimethyldiamide.

[0027] 13% SiO 2 Nanoparticles are added into the nanofiber polymer solution, stirred until uniform by magnetic force, and used as a spinneret solution.

[0028] Add the spinning solution to the electrospinning machine for electrospinning, the additional electric field strength is 2kv / cm, the distance between the receiving screen and the spinneret is 45cm, and the baking temperature is 650°C, and the SiO-containing 2 Nanoparticle fibers.

[0029] Will contain SiO 2 The nanofibers of the nanoparticles were soaked in 55% HF solution and stirred slowly for 16 hours, washed and dried to obtain a porous nanofiber fabric. ...

Embodiment 3

[0032] Dissolving the spinning material in a solvent, adding 10% polyvinylpyrrolidone, stirring evenly, to prepare a nanofiber spinning solution; the mass ratio of the textile material to the solvent is 1:7, and the nanomaterials are polyester, polyacrylonitrile and its One or more material mixtures in the copolymer and lignin, the solution is N,N-dimethyldiamide.

[0033] 8% SiO 2 Nanoparticles are added into the nanofiber polymer solution, stirred until uniform by magnetic force, and used as a spinneret solution.

[0034] Add the spinneret solution to the electrospinning machine for electrospinning, the additional electric field strength is 1kv / cm, the receiving screen is 35cm away from the spinneret, and the baking temperature is 550°C to prepare SiO-containing 2 Nanoparticle fibers.

[0035] Will contain SiO 2 The nanofibers of the nanoparticles are soaked in 45% HF solution and stirred slowly for 10 hours, washed and dried to obtain a porous nanofiber fabric.

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com