Antistatic geothermal floor

A geothermal floor and antistatic technology, which is applied to layered products, buildings, and layered products of hydraulic materials, can solve the problems of large deformation, heavy weight, and low impact resistance, and achieve improved thermal conductivity and improved The effect of heat utilization and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

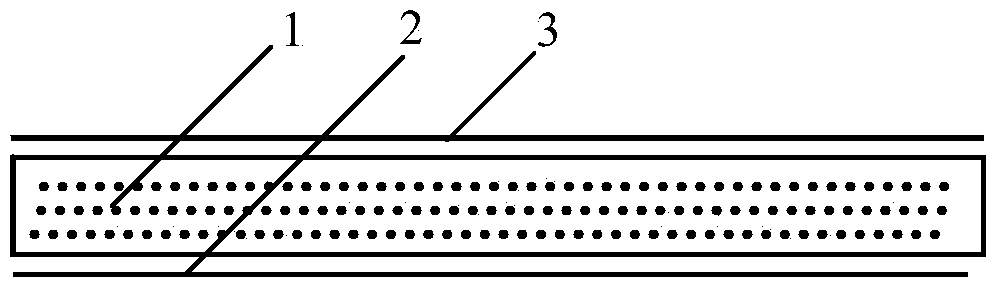

[0019] Embodiment 1: Antistatic geothermal floor, such as figure 1 As shown, it includes a decorative layer 3 on the upper surface, an antistatic layer 2 on the lower surface, and a core layer 1 sandwiched between the upper surface layer and the lower surface layer. The core layer is made of a mixture of magnesium oxysulfate cement and bamboo fiber. into the board.

[0020] Wherein, the magnesium oxysulfide cement is a cementitious material, and its components by weight percentage are: 100 parts of magnesium oxide, 30-70 parts of magnesium sulfate, and 20-70 parts of water. Such as 100 parts of magnesium oxide, 40 parts of magnesium sulfate, 30 parts of water, and an appropriate amount of accelerator. Or, 100 parts of magnesium oxide, 50 parts of magnesium sulfate, 35 parts of water, and an appropriate amount of accelerator.

[0021] The bamboo fibers are particles, and the magnesium oxysulfate cement covers each bamboo fiber particle.

[0022] The decorative layer is made ...

Embodiment 2

[0024] Embodiment 2: The mixture of the core layer further includes reinforcing fibers, and the reinforcing fibers include at least one fiber among glass fibers, plastic fibers and metal fibers. In the preparation process of the antistatic geothermal floor, in step 1, at least one fiber among glass fiber, plastic fiber and metal fiber is added in the process of mixing magnesium oxysulfate cement and bamboo fiber. Glass fibers, plastic fibers, and metal fibers also need to be processed for particle size before they are added into the mixture, and the rest of the structure and preparation process steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com