Hydraulic mechanism cover cap of automobile double-clutch transmission

A dual-clutch transmission and hydraulic mechanism technology, which is applied in the field of auto parts, can solve the problems of large surface noise radiation energy, unfavorable body layout, high noise radiation sound power, and enhance the installation and connection stiffness, avoid resonance, and improve cross-section inertia. moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

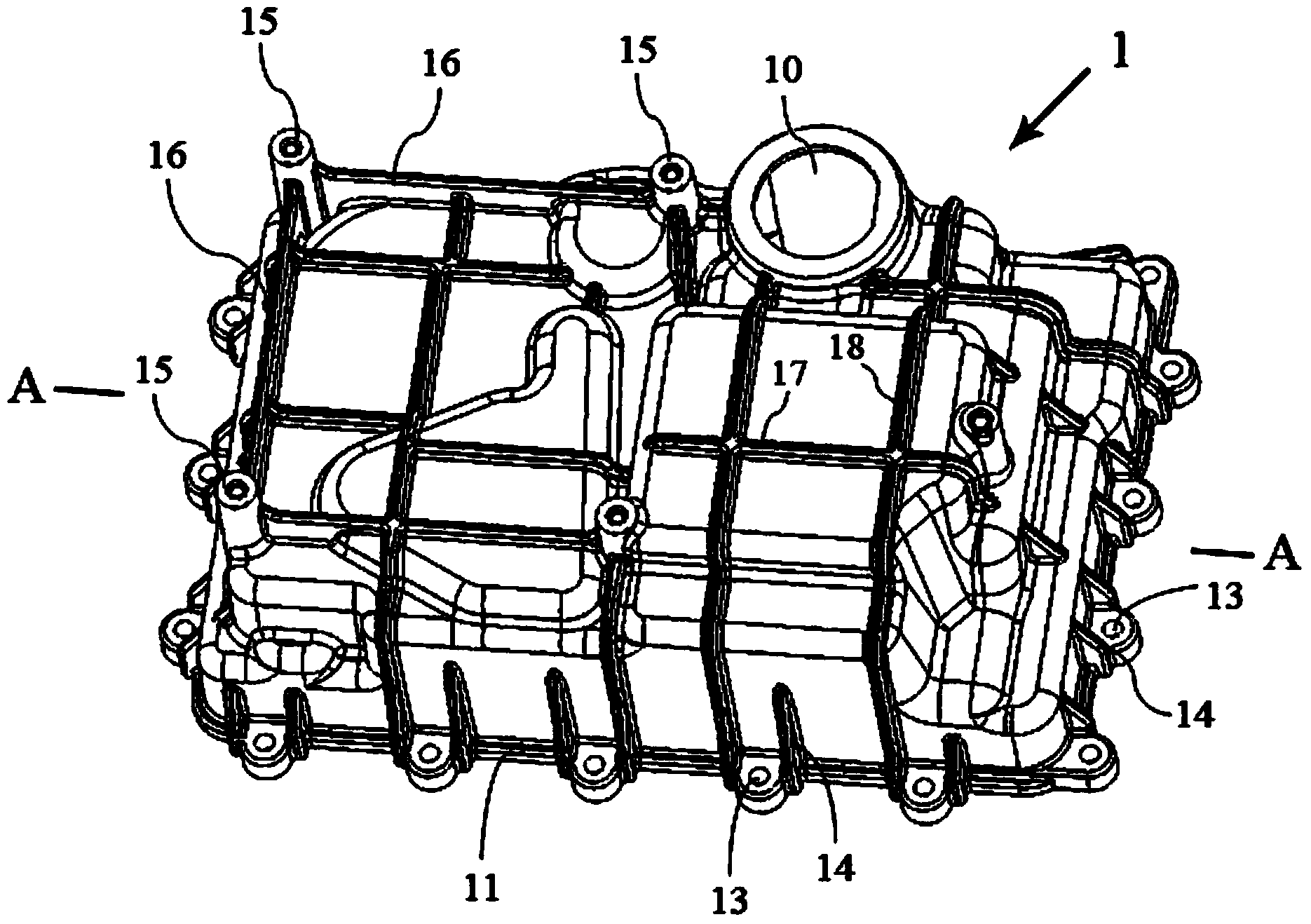

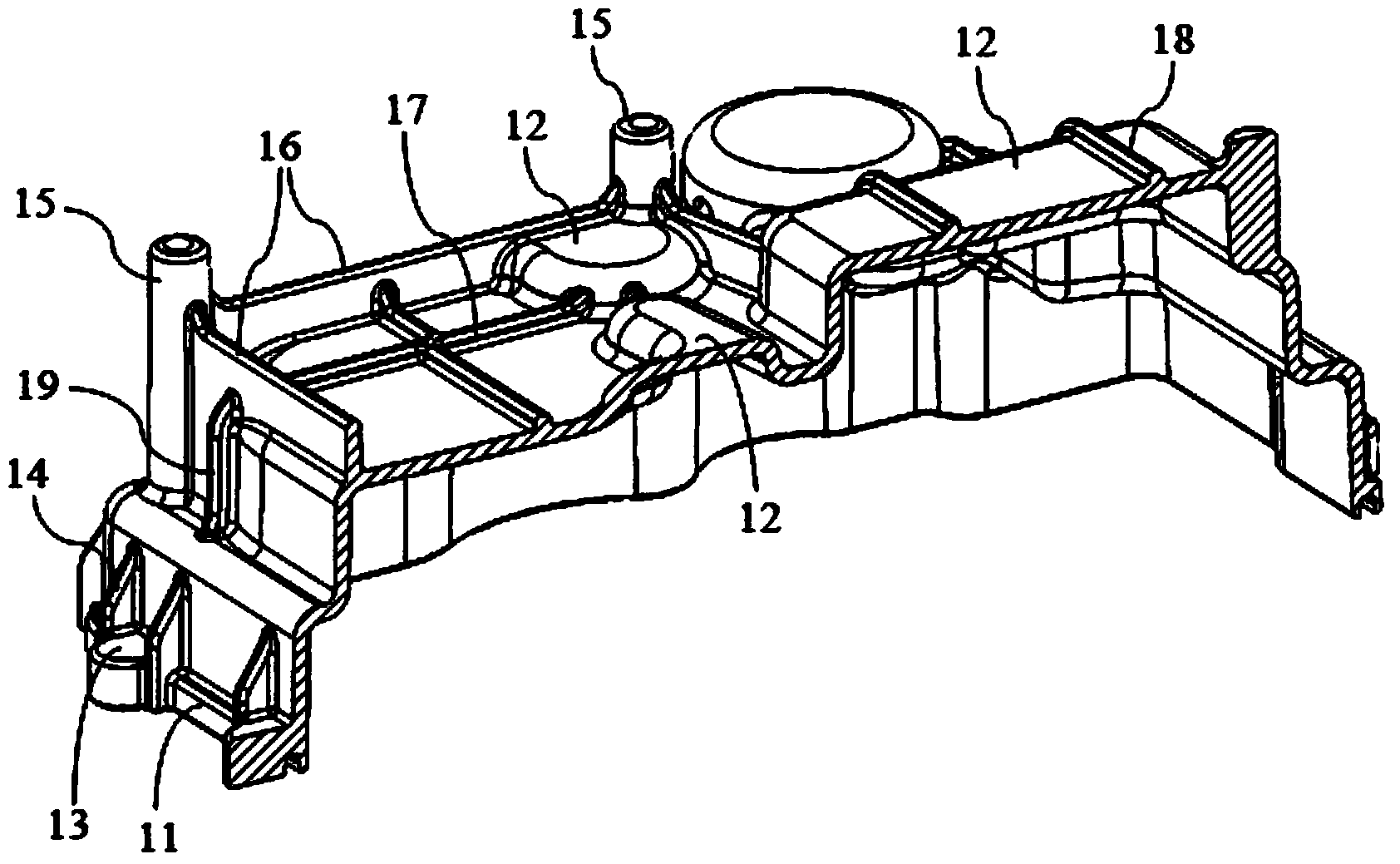

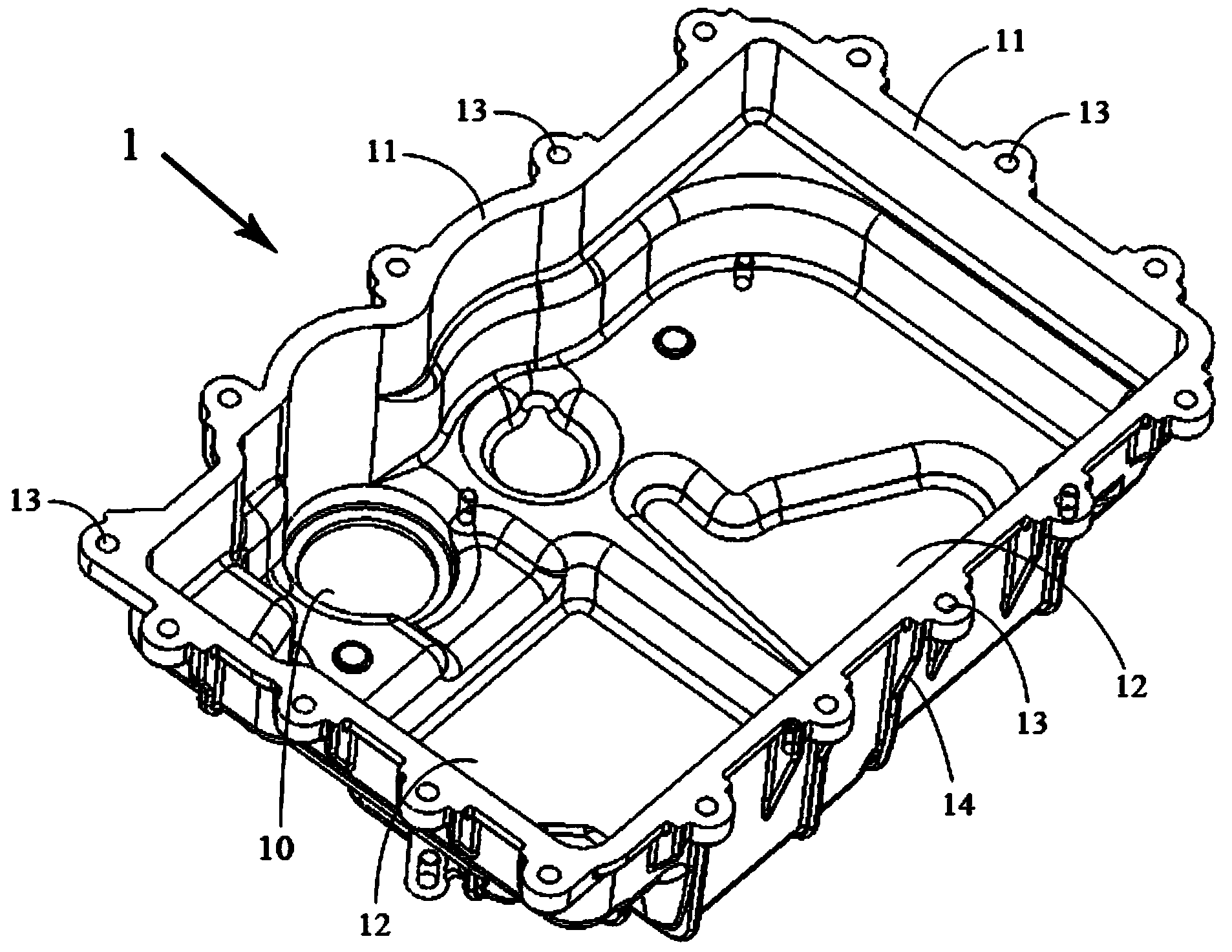

[0023] Such as Figure 1 to Figure 7 As shown, the hydraulic mechanism cover of the automobile dual-clutch transmission of the present invention includes a cover body 1, which is characterized in that: the cover body 1 is a thin-walled casting in a multi-stage step shape, and an electromagnetic valve is arranged on it. Wire hole 10 and three escape protrusions 12, lower cover along 11 are provided with a plurality of bolt holes 13. When designing the cover body, it should be noted that the avoidance protrusions should adapt to the top profile of the hydraulic control unit 3. The three avoidance protrusions of the present invention are respectively triangular, quadrangular or circular, and the number and shape of the avoidance protrusions Depending on the specific situation, it will be changed according to the change of the top profile of the hydraulic control unit; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com