Coloring combination for color filter and color filter

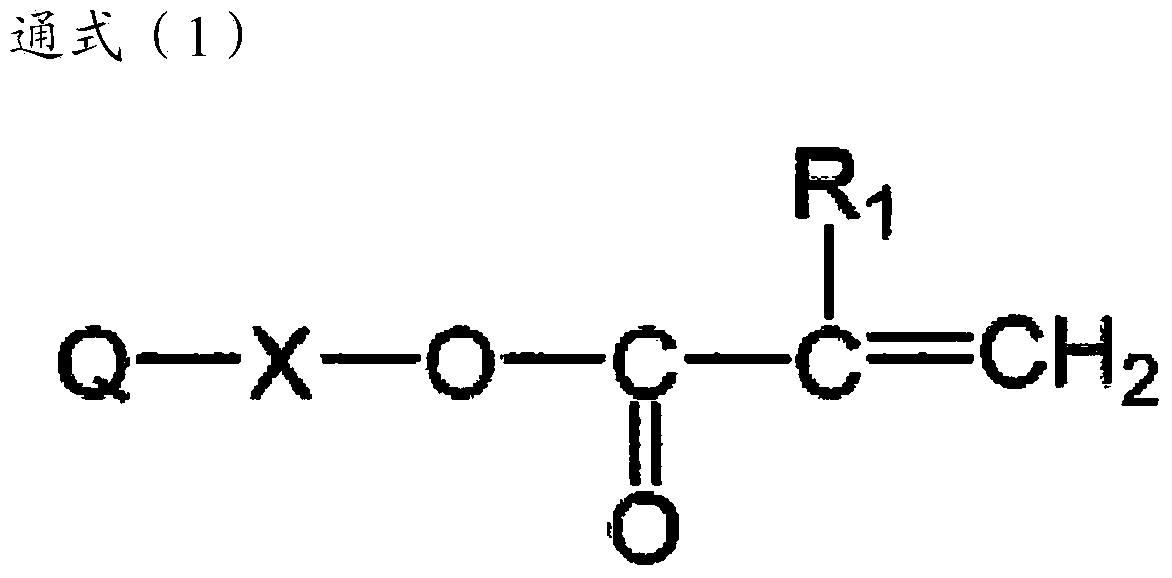

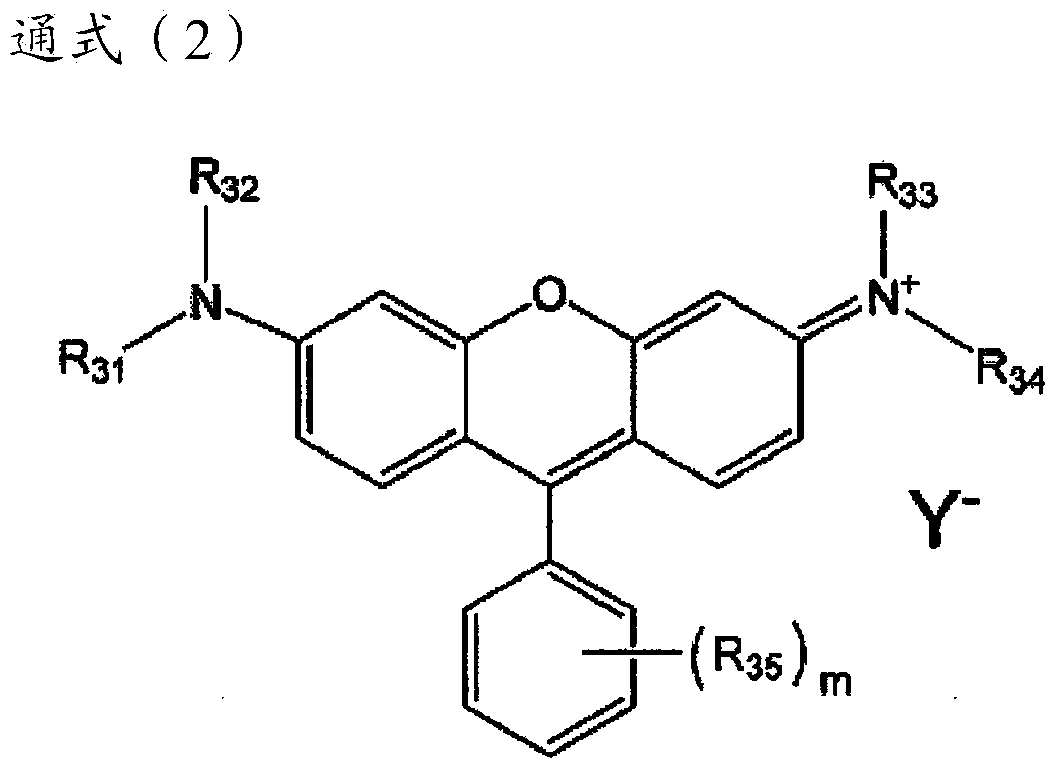

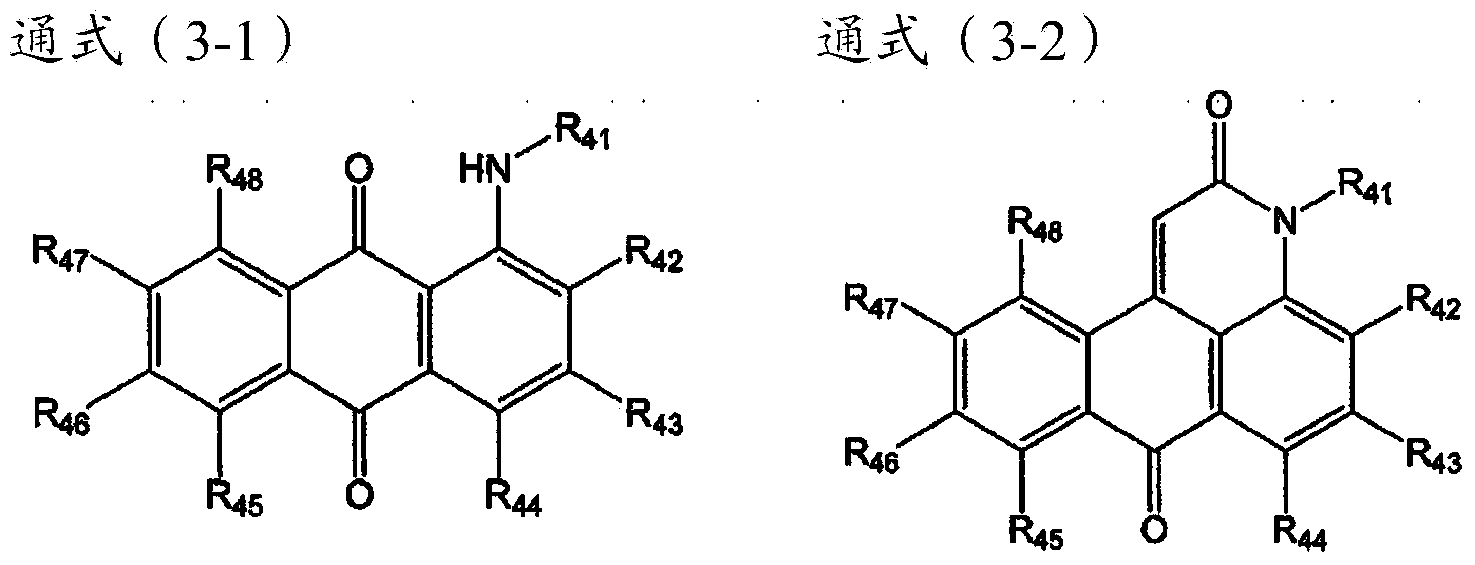

A coloring composition and color filter technology, applied in the field of color filters, can solve the problems of unsuitable parts, poor heat resistance, light fastness, poor solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0705] (Coloring Composition (SR-1))

[0706] After stirring and mixing the following mixture uniformly, it filtered with the filter of 1.0 micrometers, and obtained the coloring composition (SR-1).

[0707] Pigment monomer (A-1): 0.3 parts

[0708] Salt-forming compound (B-1): 1.4 parts

[0709] Acrylic resin solution (R-1): 47.0 parts

[0710] PGMEA: 51.3 parts

[0711] Propylene Glycol Monomethyl Ether Acetate

Embodiment 2~17、 comparative example 1~7

[0713] (Coloring composition (SR-2~24))

[0714] Except having changed to the composition and compounding quantity (weight part) shown in Table 1 and Table 2, it carried out similarly to coloring composition (SR-1), and obtained coloring composition (SR-2-24).

[0715]

[0716] About the obtained coloring composition (SR-1-24), the heat resistance test was done by the following method. The results are shown in Table 1 and Table 2.

[0717] (Evaluation of heat resistance)

[0718] The coloring composition was applied on a glass substrate so that y=0.090 in the C light source, and a substrate was produced. The luminance (Y1) of the obtained substrate was measured with a microspectrophotometer (“OSP-SP200” manufactured by Olympus Optical Co., Ltd.). Then, the substrate was heated at 230° C. for 60 minutes, and the brightness (Y2) was measured again. The value obtained by dividing (Y2) by (Y1) at this time was used as a heat resistance index. The evaluation criteria are as ...

Embodiment 18

[0729] (Resist Material (CR-1))

[0730] After stirring and mixing the following mixture uniformly, it filtered through the filter of 1.0 micrometers, and obtained the alkali developing type resist material (CR-1).

[0731] Pigment monomer (A-1): 0.3 parts

[0732] Salt-forming compound (B-1): 1.4 parts

[0733] Acrylic resin solution (R-1): 41.0 parts

[0734] dipentaerythritol hexaacrylate

[0735] ("Aronix M-402" manufactured by Toagosei Co., Ltd.): 6.0 parts

[0736] photopolymerization initiator

[0737] (BASF Japan "Irgacure OXE02"): 0.6 parts

[0738] antioxidant

[0739] ("Irganox 1010" manufactured by BASF Japan Co., Ltd.): 0.2 parts

[0740] ("Irgafos168" manufactured by BASF Japan Co., Ltd.): 0.6 parts

[0741] PGMEA: 49.9 parts

[0742] Propylene Glycol Monomethyl Ether Acetate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com