FBAR with temperature compensation function and resonance frequency tuning function and filter

A temperature compensation and frequency trimming technology, applied in electrical components, impedance networks, etc., can solve the problems of difficult precision control, tunability without considering the resonance frequency, and difficulty in releasing the sacrificial layer, achieving high frequency accuracy and improving temperature The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

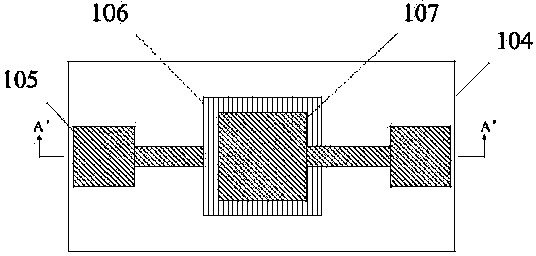

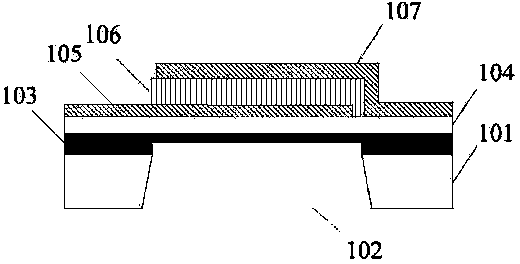

[0040] figure 1 and figure 2 They are respectively a top view and a cross-sectional view of the FBAR with the functions of temperature compensation and resonant frequency adjustment in the present invention. It is mainly composed of the following parts: Si substrate 101, cavity 102, and the SiO 2 Temperature compensation and resonant frequency trimming layer 103, Si 3 N 4 An FBAR stack composed of a support layer 104 , a Pt bottom electrode 105 , an AlN piezoelectric film 106 , and an Al top electrode 107 . The Si substrate 101 includes a cavity 102, and the interface between the bottom of the FBAR stack and the air in the cavity 102 is used as the bottom acoustic reflection boundary; the FBAR stack is made of SiO 2 The temperature compensation and resonant frequency trimming layer 103 is set on SiO 2 Si on temperature compensation and resonant frequency tuning layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com