Separation membrane element and separation membrane module

A separation membrane and element technology, applied in the field of separation membrane elements and separation membrane modules, can solve the problems of heavy weight and large thickness of the membrane support plate, and achieve the effects of high permeability, high durability and increasing the effective membrane area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Polyvinylidene fluoride (PVDF, weight-average molecular weight: 280,000) was used as the resin component for the film-forming stock solution. In addition, polyethylene glycol (PEG20,000, weight average molecular weight 20,000), N,N-dimethylformamide (DMF), and H 2 O acts as a cell opener, solvent and non-solvent, respectively. These were sufficiently stirred at a temperature of 95° C. to prepare a membrane-forming stock solution having the following composition.

[0129]

[0130] Set the density to 0.42g / cm 3 , A non-woven fabric made of rectangular polyester fibers with a size of 50cm wide x 150cm long is used as a substrate, the above film-making stock solution is cooled to 30°C and coated on the substrate, and immediately immersed in pure water at 20°C after coating for 5 minutes, and further immersed in hot water at 90°C for 2 minutes to wash off the solvent N,N-dimethylformamide and the cell opener polyethylene glycol. Thereafter, it was immersed in an aqueou...

Embodiment 2

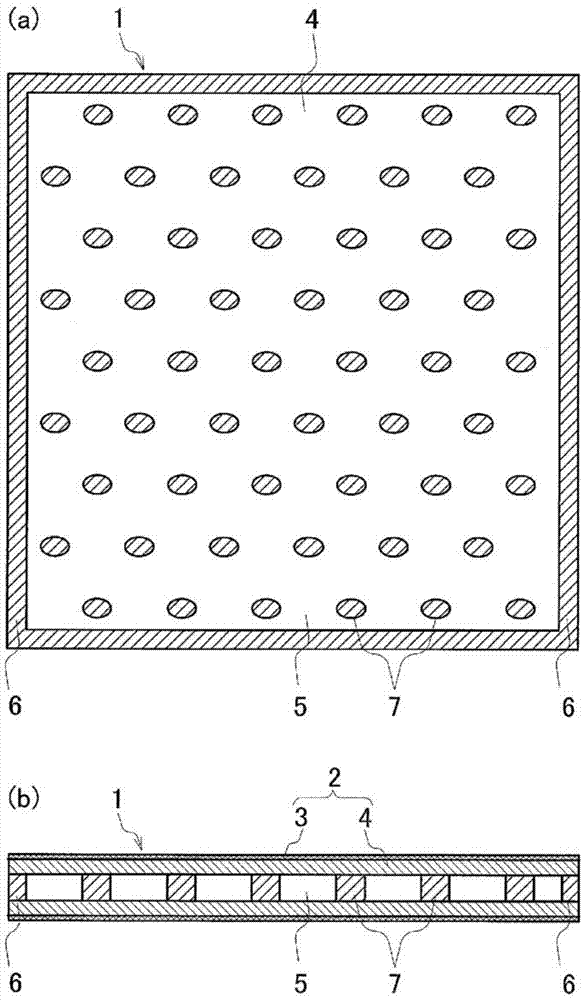

[0136] The element was produced and evaluated in the same manner as in Example 1, except that the height of the coating ethylene vinyl acetate copolymer resin and the thickness of the separator aluminum plate were changed so that the gap on the permeation side of the separation membrane was 0.05 mm (50 μm). ), and as a result, the inner resin portion is roughly oval dot-shaped with a major diameter of 8.0 mm, a minor diameter of 4.5 mm, a vertical interval of 4.0 mm, and a horizontal interval of 2.5 mm, and its area ratio is 35% (refer to figure 1 ). It should be noted that the cross-sectional shape of the inner resin portion is substantially rectangular. The water permeability of the separation membrane is 24.6×10 -9 m 3 / m 2 / s / Pa, this value is lower than embodiment 1. Table 1 shows the results of the area ratio of the resin portion, the gap on the permeation side, and the water permeability.

Embodiment 3

[0138] The separation membrane element was produced and evaluated in the same manner as in Example 1, except that the height of the coated ethylene vinyl acetate copolymer resin and the thickness of the separator aluminum plate were changed so that the gap on the permeation side of the separation membrane was 2 mm ( 2000 μm), as a result, the inner resin part is roughly oval dots with a major diameter of 8.0 mm, a minor diameter of 4.5 mm, a vertical interval of 4.0 mm, and a horizontal interval of 2.5 mm, and its area ratio is 35% (refer to figure 1 ). In addition, the cross-sectional shape of the inner resin portion is substantially rectangular. The water permeability of the separation membrane is 25.8×10 -9 m 3 / m 2 / s / Pa, this value is almost equal to Example 1. Table 1 shows the results of the area ratio of the resin portion, the gap on the permeation side, and the water permeability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com