Preparation of la Modified Alumina Support and Support and Catalyst for Dehydrogenation of Long-chain Alkanes

An alumina carrier, dehydrogenation catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problems of side reactions, surface area carbon, catalyst deactivation, etc. , to achieve the effect of large pore volume, high strength and low heap ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

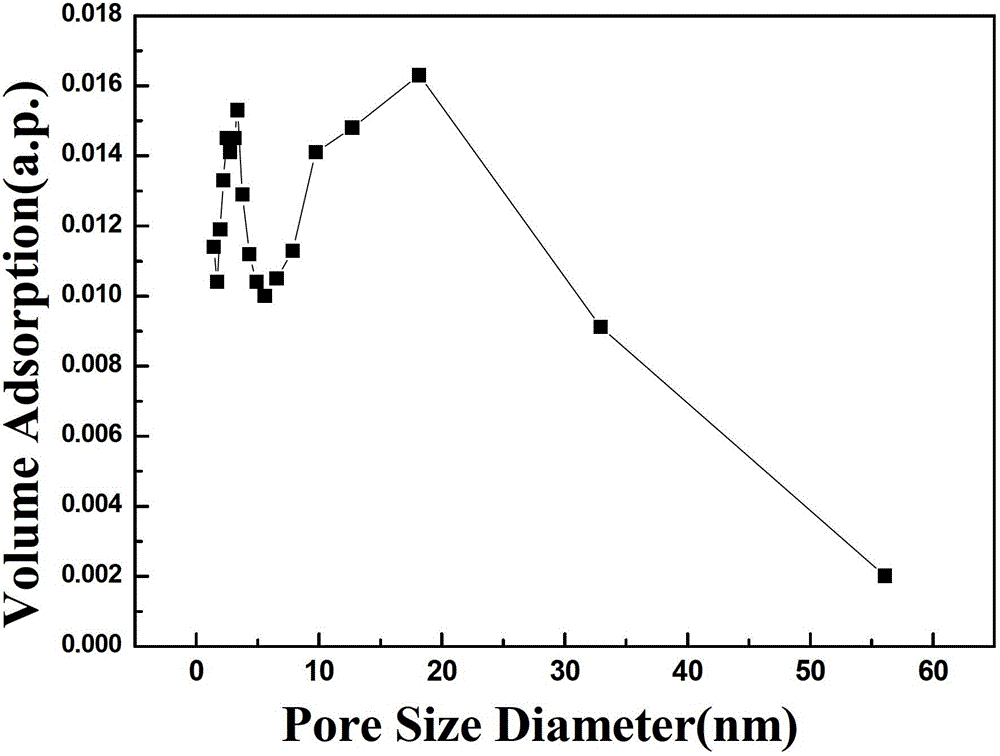

[0019] Embodiment 1: the preparation of alumina carrier

[0020] Weigh 30g of aluminum foil with a purity equal to 99.9%, add 253.3g of 10% hydrochloric acid solution, dissolve it at 98°C, and obtain a transparent aluminum sol after filtration.

[0021] Take 50 g of the prepared aluminum sol, add urotropine solution containing 6.5 g of urotropine with a mass fraction of 40%, mix well, and drop into 90 ° C oil (mixture of C10-C13 alkanes) column to form The balls are aged for 4-5 hours at 140°C for 8 hours, then taken out, rinsed with deionized water, dried at 120°C for 4 hours, and calcined at 600°C for 8 hours to obtain a spherical alumina carrier. Weigh 30g of aluminum foil, add 253.3g of 10% hydrochloric acid solution, dissolve it at 90-100°C, and obtain a transparent aluminum sol after filtration.

Embodiment 2

[0022] Embodiment 2: Preparation of La modified alumina carrier

[0023] Take by weighing the aluminum sol 50g that prepares in the embodiment 1, add the massfraction containing urotropine 6.5g and be 40% urotropine solution, then add the lanthanum nitrate solution 1.18ml that lanthanum concentration is 0.1g / ml, mix After uniformity, then use a dropper to drop it into 90°C oil (C 10 -C 13 Mixture of alkanes) into a ball for 4-5 hours, aged at 140°C for 8 hours, then taken out, rinsed with deionized water, dried at 120°C for 4 hours, and calcined at 600°C for 8 hours to obtain a La-modified spherical alumina carrier.

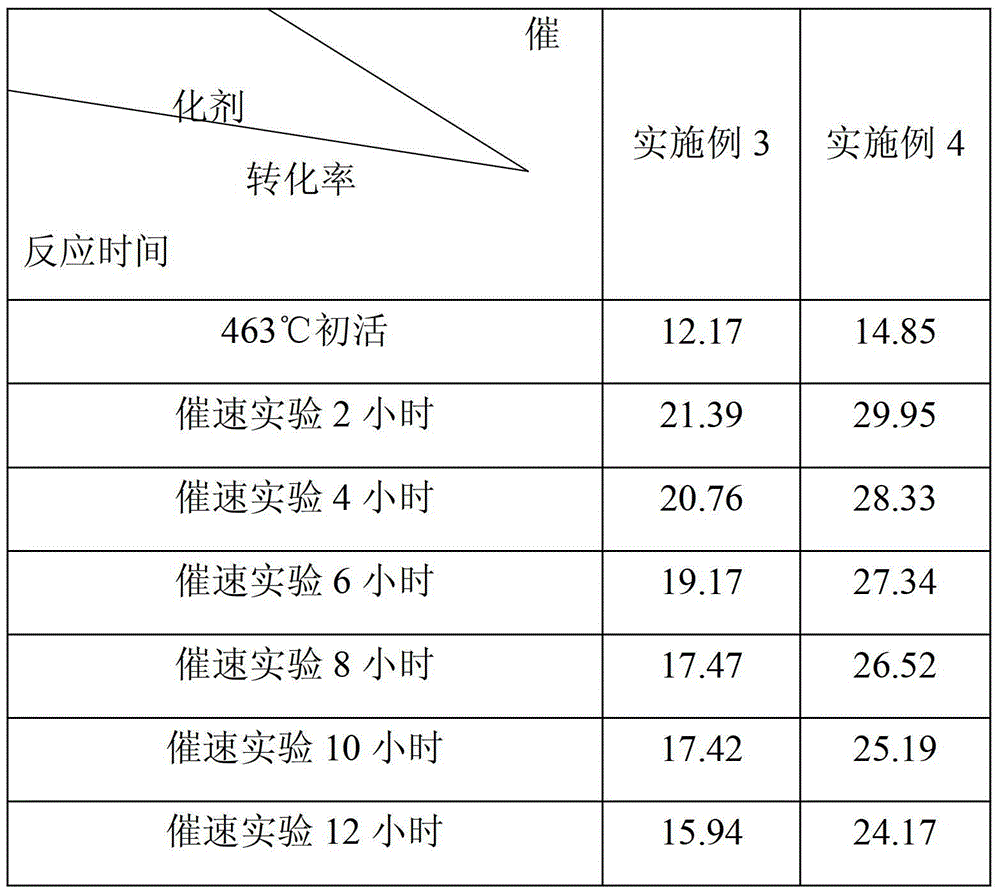

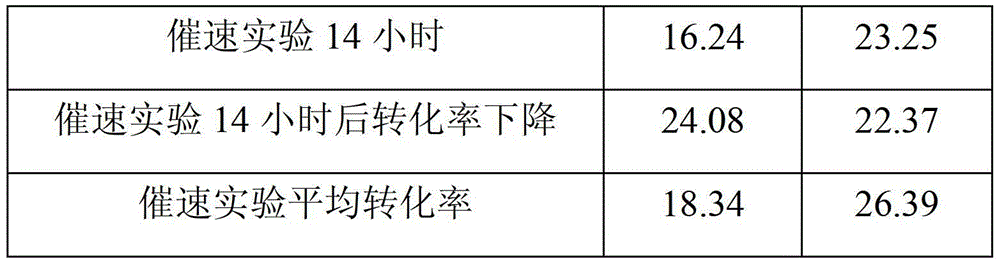

Embodiment 3

[0024] Embodiment 3: Alumina is the catalyst preparation of carrier

[0025] Take by weighing 7.2 grams of the carrier prepared in Example 1 and place it in a vacuum impregnator, and simultaneously take platinum concentration as 1.8ml of chloroplatinic acid aqueous solution of 0.02g / ml, 0.82ml of concentrated hydrochloric acid, 0.06g / ml of phosphite chloride containing tin 1.8ml of tin aqueous solution and 0.72ml of potassium chloride aqueous solution with a potassium concentration of 0.04g / ml. Add the above impregnating solution into a vacuum impregnator equipped with a carrier, dry it at 120°C for 2 hours after uniform impregnation, roast it in a muffle furnace at 520°C for 4 hours, and reduce it with pure hydrogen (purity>99.9%) with a water content of less than 20ppm at 470°C 2h, the catalyst C1 was obtained. The composition of the obtained catalyst is: platinum: 0.5%, tin 1.5%, potassium 0.40% (to the carrier weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com