Quick collapsed suspension liquid compound fertilizer and preparation method thereof

A technology for suspending liquid and compound fertilizers, which is applied in fertilization methods, fertilizer mixtures, fertilization devices, etc. It can solve the problems of reducing the use effect of suspended liquid fertilizers, sinking to the bottom of pools or buckets, formulation viscosity and specific gravity, etc., to speed up Effects of dissolution speed, improvement of use efficiency, and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare raw materials according to the following parts by weight:

[0038] Concentrated alcohol waste

24 parts by weight

[0039] urea

16 parts by weight

ammonium nitrophosphate

16 parts by weight

2 parts by weight

5 parts by weight

28 parts by weight

EDTA-Zn

1 part by weight

polysodium borate

1 part by weight

0.5 parts by weight

0.7 parts by weight

pull open powder

0.6 parts by weight

Sodium lignosulfonate

0.8 parts by weight

0.4 parts by weight

sodium tripolyphosphate

1 part by weight

water

3 parts by weight

[0040] The specific preparation method is:

[0041] (1) Add xanthan gum and urea successively to 16 parts by weight of concentrated alcohol waste liq...

Embodiment 2

[0048] Prepare raw materials according to the following parts by weight:

[0049] Concentrated alcohol waste

28 parts by weight

16 parts by weight

ammonium nitrophosphate

14 parts by weight

Ammonium dihydrogen phosphate

2 parts by weight

Diammonium hydrogen phosphate

3 parts by weight

27 parts by weight

EDTA-Zn

1 part by weight

polysodium borate

1 part by weight

0.8 parts by weight

guar gum

1.2 parts by weight

pull open powder

0.6 parts by weight

Sodium polycarboxylate

1 part by weight

0.8 parts by weight

1.6 parts by weight

water

2 parts by weight

[0050] The specific preparation method is:

[0051] (1) Add xanthan gum and urea successively to 18 parts by weight of concentrated alcohol waste liquid, stir while heating, contro...

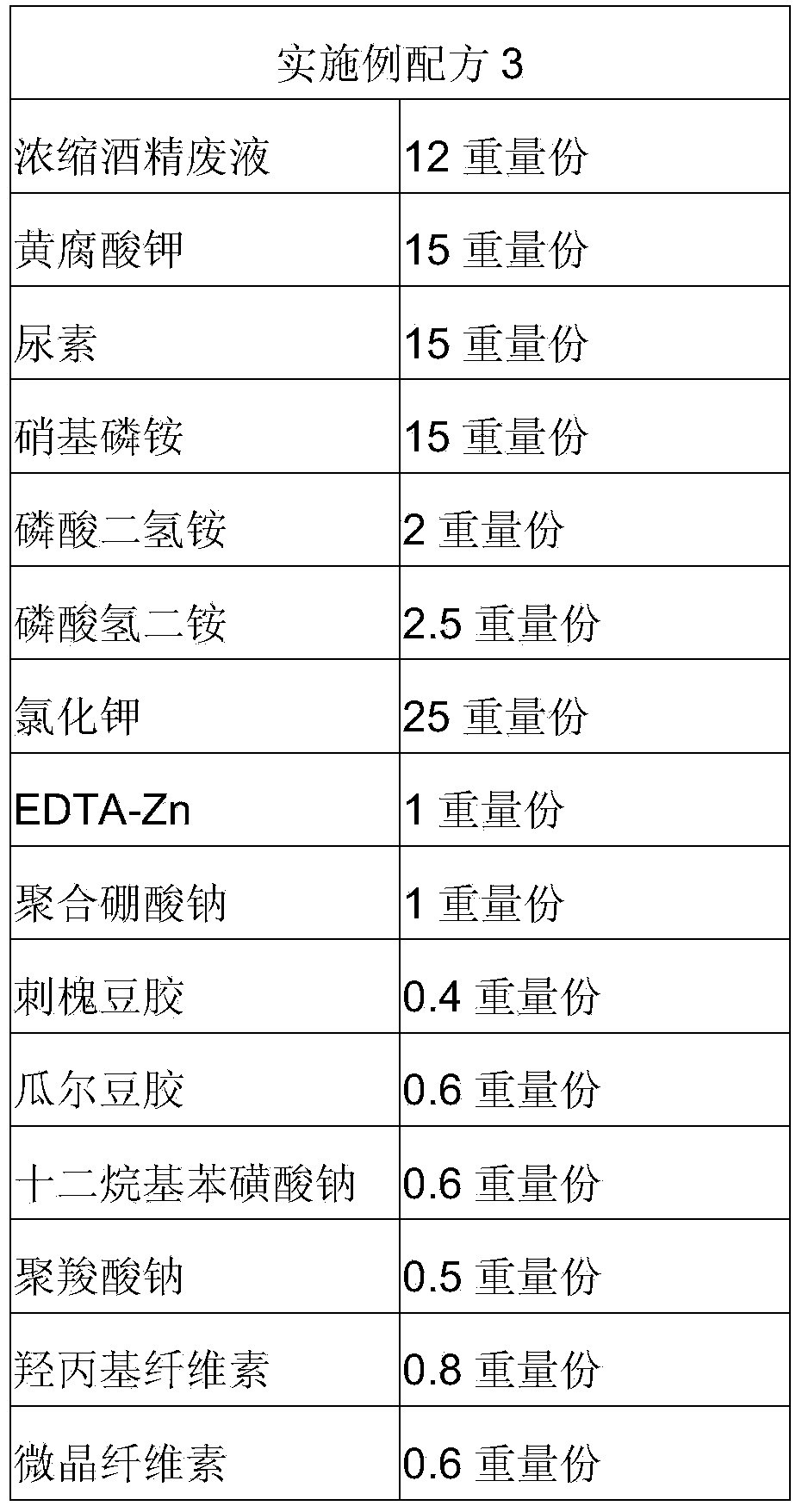

Embodiment 3

[0056] Prepare raw materials according to the following parts by weight:

[0057]

[0058]

[0059] The specific preparation method is:

[0060] (1) Add locust bean gum and urea in turn to 12 parts by weight of concentrated alcohol waste liquid, stir while heating, control the temperature between 55-70°C, and continue stirring for 15 minutes after the urea in the mixed solution is completely dissolved. -25 minutes, a gel-like premix A was obtained.

[0061] (2) Guar gum, sodium dodecylbenzenesulfonate, sodium polycarboxylate, ammonium nitrophosphate, ammonium dihydrogen phosphate, diammonium hydrogen phosphate, potassium humate are added to the water of 8 parts by weight, while Stir while heating, control the temperature between 65-80°C, and stir for 20-30 minutes to obtain a gel-like premix B.

[0062] (3) Slowly pour the gel premix B into the gel premix A, stir for 5-10 minutes, and then cut it with a high-speed shear emulsifier for 20-30 minutes to obtain the gel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com