Catalyst component, catalyst and method for olefin polymerization

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst components, olefin polymerization catalysts and olefin polymerization, can solve the problems of low polymerization yield, low isotactic index, etc., and achieve the effect of high polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Generally, the preparation method of the alcohol adduct of described spherical magnesium dichloride can comprise: by magnesium dichloride and R 0 OH is subjected to high shear at a temperature of 90-140°C in the dispersion medium, and then the obtained reaction product is placed in a cooling medium at a temperature of -20°C to 0°C to form spherical particles, which can be washed and dried A spherical alcohol adduct of magnesium dichloride is obtained. The high shear method can be, for example, the method disclosed in CN1330086, the method disclosed in US6020279, the method disclosed in CN1580136A and the method disclosed in CN1463990A. The dispersion medium may be a hydrocarbon solvent such as kerosene, white oil, silicone oil, paraffin oil and vaseline oil. The cooling medium can be pentane, hexane, heptane, petroleum ether and raffinate oil in the petroleum refining process.

[0064] A catalyst component obtained by reacting the alcohol adduct of magnesium dichlorid...

Embodiment 1

[0099] This example is used to illustrate the olefin polymerization catalyst component, olefin polymerization catalyst and olefin polymerization method of the present invention.

[0100] In a 300ml stirred glass reaction bottle fully replaced with high-purity nitrogen, add 90mL of titanium tetrachloride, cool to -20°C, and add 8g of spherical magnesium dichloride alcohol adduct (MgCl 2 2.6C 2 h 5 OH, synthesized with magnesium dichloride and ethanol according to the method disclosed in CN1330086A), the temperature was slowly raised to 110°C in stages, and diethyl ethoxymethylene malonate (internal electron donor compound a, Formula II, R' 1 is ethoxy, R 3 and R 4 is ethyl) 0.0025 mol and 2,4-pentanediol dibenzoate (internal electron donor compound b) 0.0067 mol, kept at 110 ° C for 0.5 h, filtered off the liquid, and poured into the solid phase obtained by filtration Add 80 mL of titanium tetrachloride and stir twice, then wash with 60 mL of hexane five times, and dry in ...

Embodiment 2

[0103] This example is used to illustrate the olefin polymerization catalyst component, olefin polymerization catalyst and olefin polymerization method of the present invention.

[0104] The olefin polymerization catalyst component was prepared according to the method of Example 1, except that 0.005 mol of diethyl ethoxymethylene malonate was added to obtain catalyst component A2.

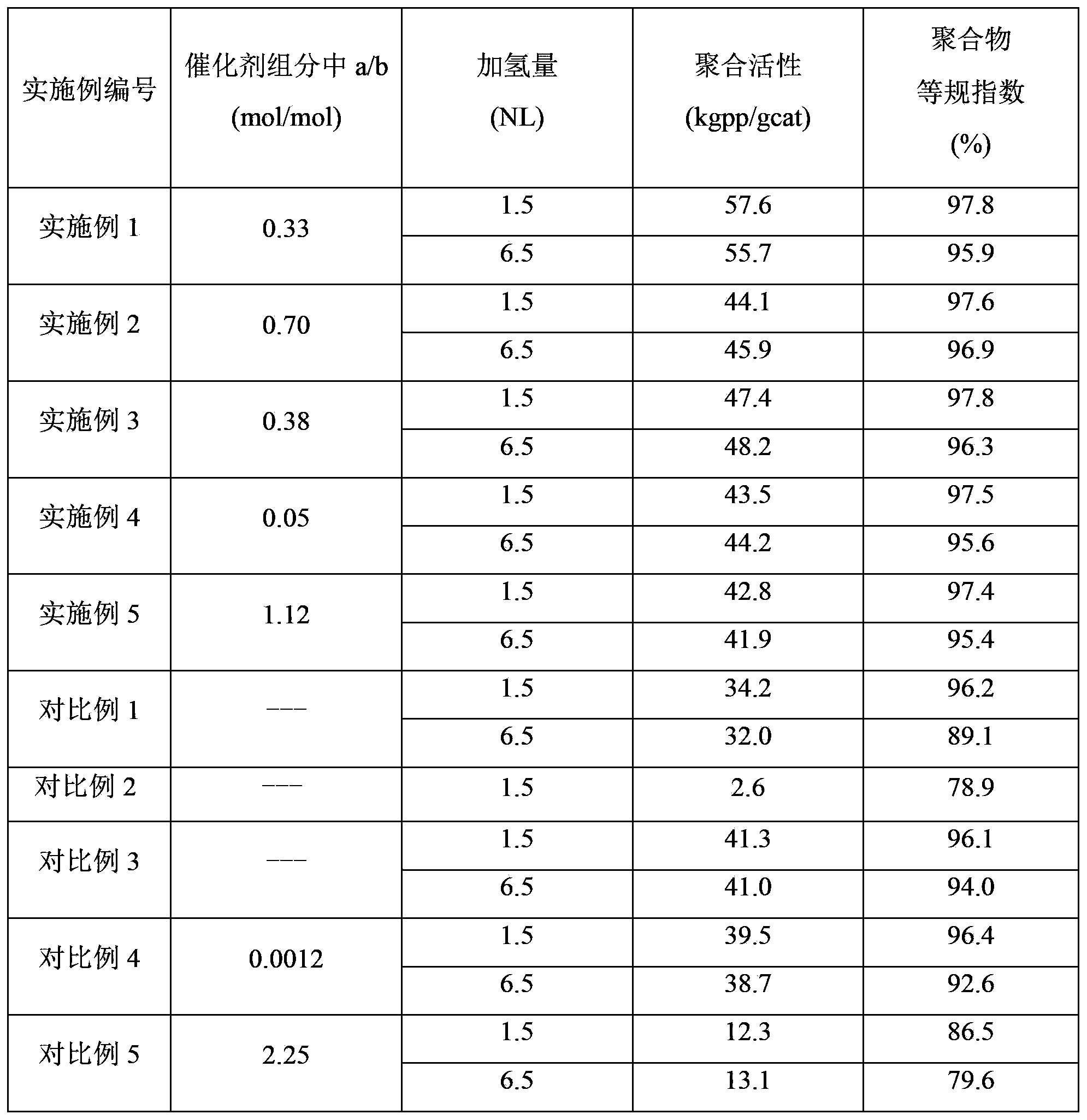

[0105] And prepare polypropylene according to the method of embodiment 1, the amount of hydrogen added is shown in table 1. Table 1 shows the test results of the isotactic index of the obtained polypropylene and the polymerization activity of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com