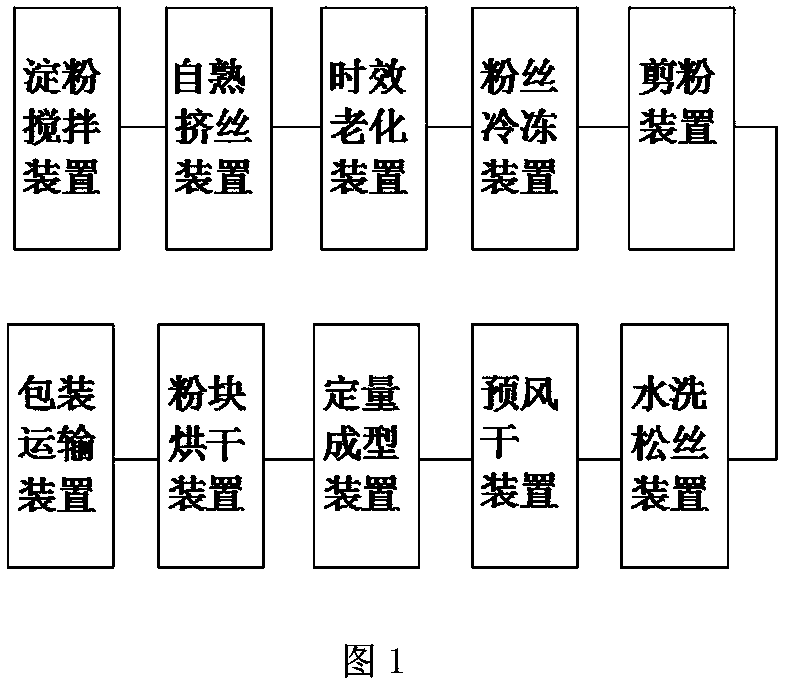

Sweet potato vermicelli processing method and production line thereof

A technology of sweet potato vermicelli and a processing method, applied in the field of food processing, can solve the problems of affecting air-drying and baking processes, increasing production costs, wasting water resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

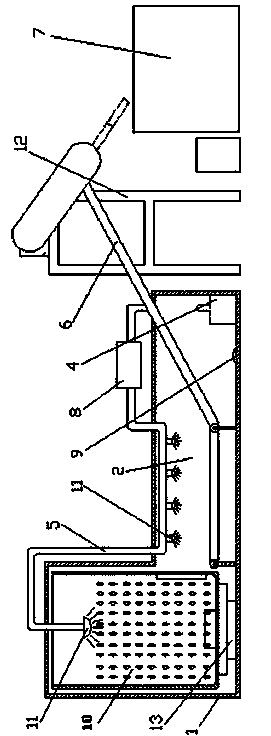

Method used

Image

Examples

Embodiment 1

[0039] a. Make emulsion: make emulsion with prepared oil and boiling water for brewing at a ratio of 1:2, and keep the temperature of emulsion at 80°C;

[0040] B, and material: sweet potato starch, cornstarch, potato starch, tapioca starch are mixed, and the parts by weight of its each component are 30,5,1,4.5; Add normal temperature clean water accounting for 45% of the total weight of raw materials, and alternately stir counterclockwise and clockwise for 15 minutes to form a powder-free particle slurry;

[0041] c. Ripening: input the slurry raw material into a twin-screw extruder for high-pressure ripening and extruding into silk, and the high-pressure steam pressure used is 0.4MPa;

[0042] d. Air cooling: Blow the ripened sweet potato vermicelli to make the moisture on the surface evaporate faster and prevent the vermicelli from sticking and drawing;

[0043]e, Aging: Cut the formed vermicelli into a length of 180 cm and lay it flat on the aging car board, after 1 hour ...

Embodiment 2

[0061] a. Make emulsion: make emulsion with prepared oil and boiling water for brewing at a ratio of 1:2, and keep the temperature of emulsion at 80°C;

[0062] B, and material: sweet potato starch, cornstarch, potato starch, cassava starch are mixed, and the parts by weight of its each component are 32.5, 7.5, 2.5, 7.5, pour above-mentioned emulsion and mixed starch into mixer and mix, then Add normal temperature clean water accounting for 50% of the total weight of raw materials, and alternately stir counterclockwise and clockwise for 20 minutes to form a raw powder-free particle slurry;

[0063] c. Ripening: input the slurry raw material into a twin-screw extruder for high-pressure ripening and extruding into silk, and the high-pressure steam pressure used is 0.4MPa;

[0064] d. Air cooling: Blow the ripened sweet potato vermicelli to make the moisture on the surface evaporate faster and prevent the vermicelli from sticking and drawing;

[0065] e, Aging: Cut the formed ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com