A method for comprehensive utilization of coal gangue

A technology for coal gangue and coal gangue fine powder, applied in chemical instruments and methods, removal of silicon compounds, solid waste, etc., can solve the problems of polysulfuric acid, easy to see, low yield of cryolite, etc., and achieve high utilization rate , low cost, and the effect of improving comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Acid leaching of coal gangue

[0048] 1.1) Coarsely grind the coal gangue block and place it in a ceramic crucible, calcinate it in an electric furnace at 750°C for 1.5 hours, take it out and cool it to room temperature in the air to obtain calcined coal gangue; put the calcined coal gangue into a ball mill tank for dry ball milling 24h, cross 180 mesh sieves to obtain coal gangue fine powder;

[0049] 1.2) Prepare concentrated sulfuric acid with a mass concentration of 65% with deionized water, then add coal gangue fine powder to the concentrated sulfuric acid at a liquid-solid ratio of 5mL / g, heat and stir at a constant temperature at 90°C for 2 hours in a constant temperature water bath To carry out acid leaching to obtain an acid leaching product;

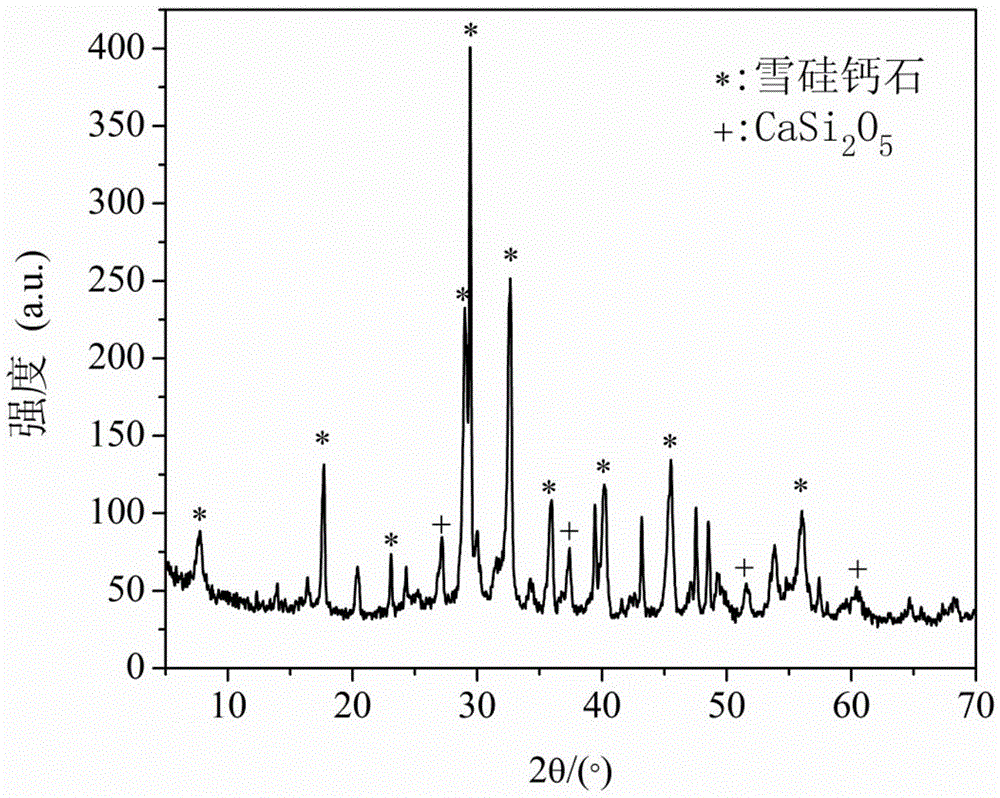

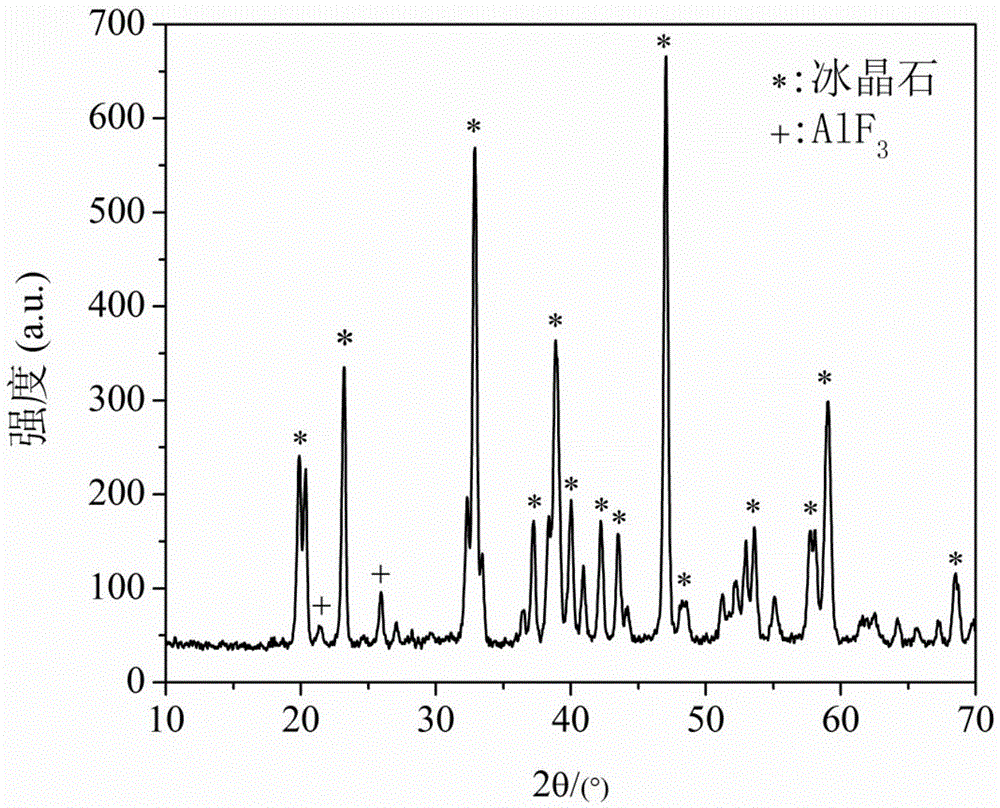

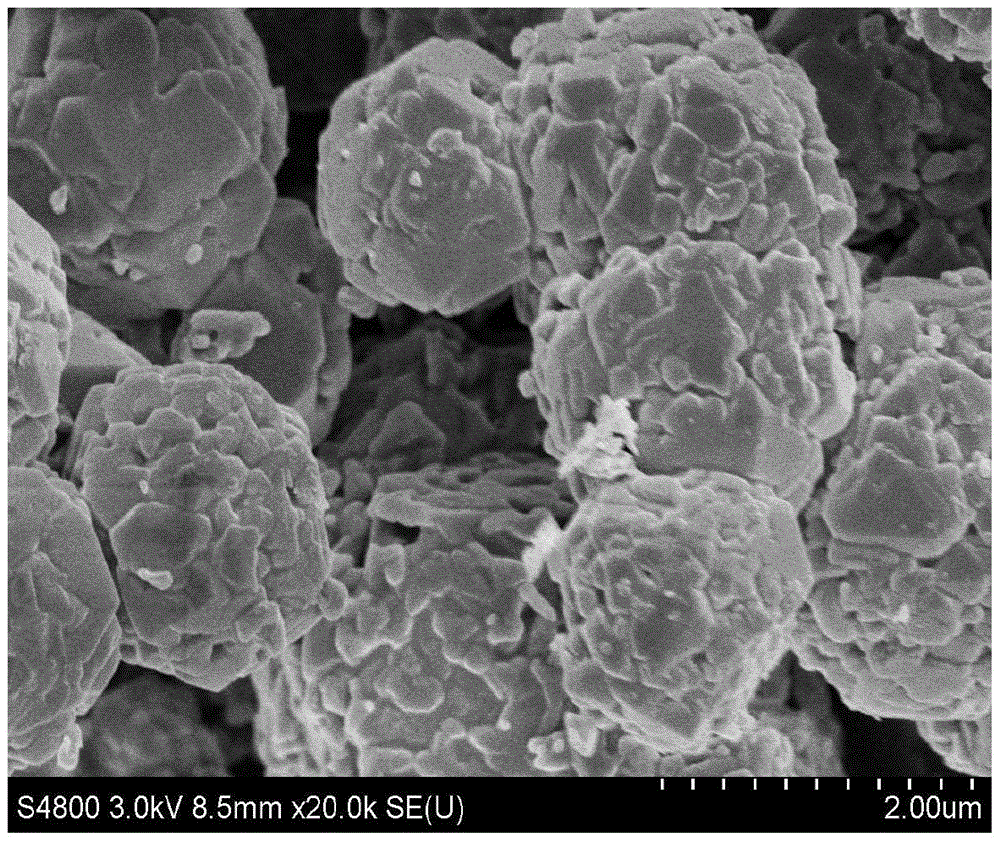

[0050] 1.3) The acid extraction product is subjected to centrifugal filtration to separate the solid from the liquid, and the clear liquid obtained after the solid-liquid separation is the aluminum sulfate solution f...

Embodiment 2

[0063] 1) Acid leaching of coal gangue

[0064] 1.1) Coarsely grind the coal gangue block and place it in a ceramic crucible, calcinate it in an electric furnace at 700°C for 2 hours, take it out and cool it to room temperature in the air to obtain calcined coal gangue; put the calcined coal gangue into a ball mill tank for dry ball milling for 24 hours , through a 200-mesh sieve to obtain coal gangue fine powder;

[0065] 1.2) Prepare concentrated sulfuric acid with a mass concentration of 60% with deionized water, then add coal gangue fine powder into the concentrated sulfuric acid at a liquid-solid ratio of 5.5mL / g, heat and stir at a constant temperature at 95°C in a constant temperature water bath 2h to carry out acid leaching to obtain the acid leaching product;

[0066] 1.3) The acid extraction product is subjected to centrifugal filtration to separate the solid from the liquid, and the clear liquid obtained after the solid-liquid separation is the aluminum sulfate sol...

Embodiment 3

[0074] 1) Acid leaching of coal gangue

[0075] 1.1) Coarsely grind the coal gangue block and place it in a ceramic crucible, calcinate it in an electric furnace at 730°C for 2 hours, take it out and cool it to room temperature in the air to obtain calcined coal gangue; put the calcined coal gangue into a ball mill tank for dry ball milling for 24 hours , cross 180 mesh sieves to obtain coal gangue fine powder;

[0076] 1.2) Prepare concentrated sulfuric acid with a mass concentration of 65% with deionized water, then add coal gangue fine powder into the concentrated sulfuric acid at a liquid-solid ratio of 5.2mL / g, heat and stir at a constant temperature at 85°C in a constant temperature water bath 2.5h to carry out acid leaching to obtain the acid leaching product;

[0077] 1.3) The acid extraction product is subjected to centrifugal filtration to separate the solid from the liquid, and the clear liquid obtained after the solid-liquid separation is the aluminum sulfate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com