Preparation of ultra-dispersed nano diamond hydrosol

A nano-diamond and dispersion technology, applied in the direction of medical preparations of non-active ingredients, nanotechnology, nanotechnology, etc., can solve the problem that it is difficult to obtain primary particle hydrosol, and achieve high yield, simple processing, and simple technical process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

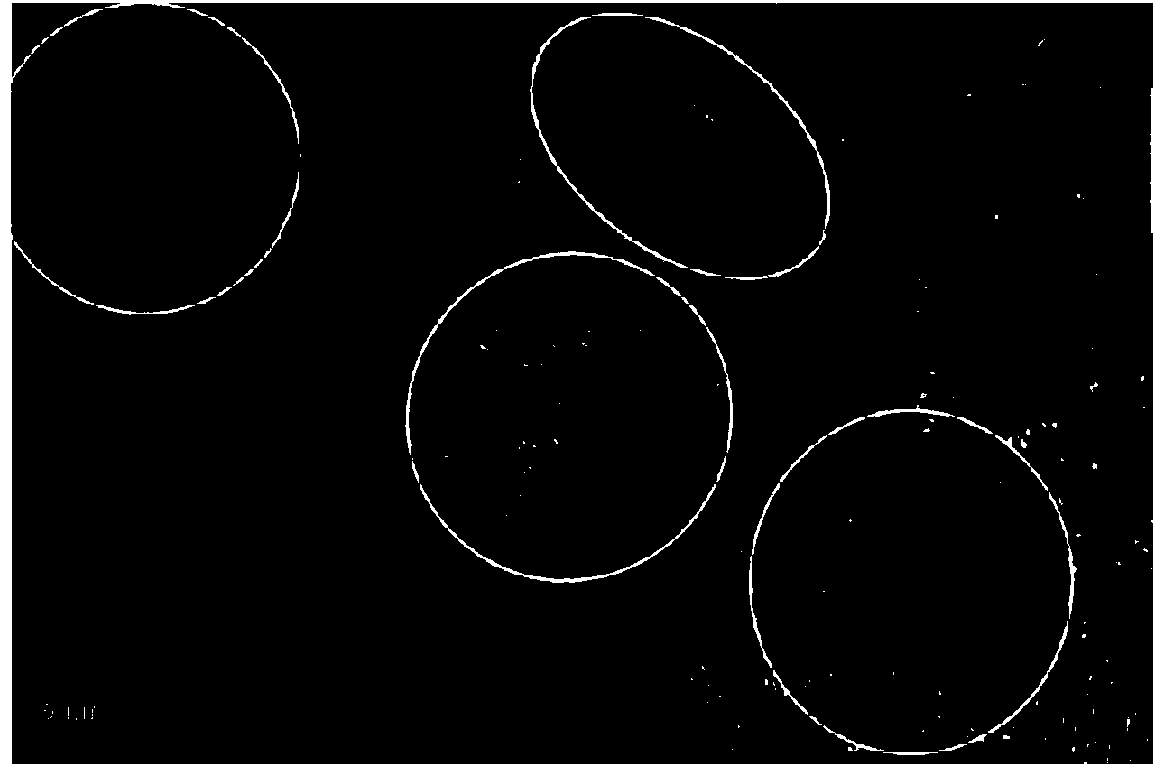

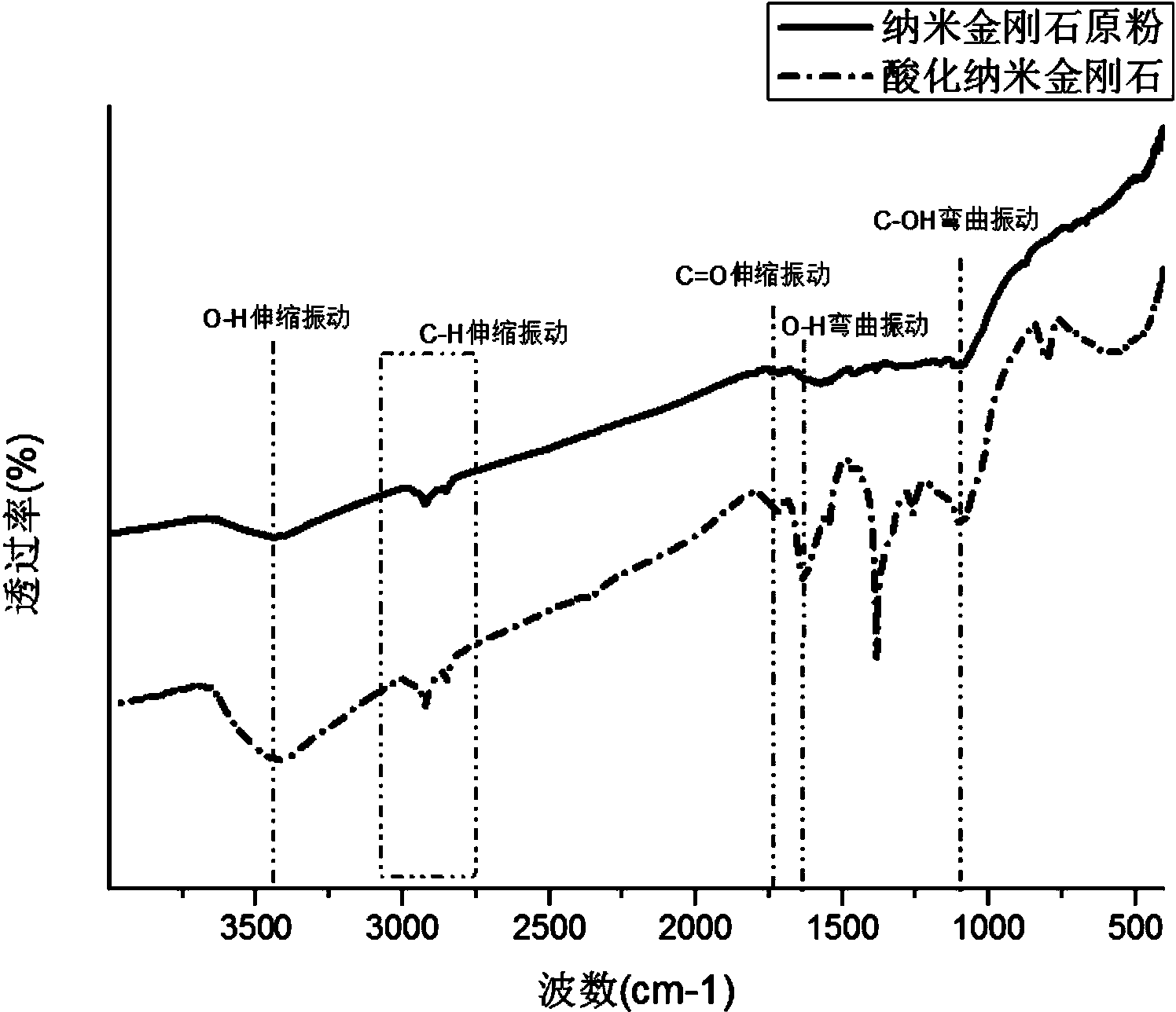

[0035] a. Add 2g of nano-diamond raw powder obtained by detonation method (Qinghai Microcrystalline Nano Technology Co., Ltd.) into a high-temperature reactor, and add 40ml of concentrated HNO3 to react at 200°C for 4 hours. After the reaction, take out the nano-diamond with deionization The acidified nano-diamond was obtained by repeated washing with water to neutrality; through Fourier transform infrared spectroscopy and transmission electron microscopy, it was found that compared with the raw nano-diamond powder, the hydrophilic functional groups on the surface were more, and the lattice fringes were clearer. figure 2 and 3 .

[0036] b. Take 200g of ball milling beads with a diameter of 0.02-0.03mm and put them into a ball milling jar with a volume of 50ml, add 2g of acidified nano-diamond and 20ml of deionized water, and set up a ball mill (model: QM-DY2, Nanjing Nanda Instrument Factory ) rotating speed is 650r / min, the ball milling time is 6h, and ball milling is carr...

Embodiment 2

[0040] a. Add 2g of nano-diamond raw powder obtained by the detonation method into a high-temperature reaction kettle, and add 40ml of concentrated HNO3 to react at 200°C for 4 hours. After the reaction, take out the nano-diamond and wash it repeatedly with deionized water until neutral to obtain acidification nanodiamond.

[0041] b. Take 200g of ball milling beads with a diameter of 0.02-0.03mm and put them into a ball milling jar with a volume of 50ml, add 2g of acidified nano-diamonds and 20ml of deionized water, set the ball mill speed to 650r / min, and the ball milling time to 6h, A small amount of liquid nitrogen was introduced to maintain the temperature between 0°C and 20°C for ball milling to obtain an initially dispersed nano-diamond aqueous solution.

[0042] c. Add 60ml of deionized water to the taken out ball milling beads and nano-diamond aqueous solution for ultrasonication. The power is 800W, and the ultrasonication time is 3h.

[0043]d. Take out the nano-dia...

Embodiment 3

[0045] a. Add 2g of nano-diamond raw powder obtained by the detonation method into a high-temperature reaction kettle, and add 40ml of concentrated HNO3 to react at 200°C for 4 hours. After the reaction, take out the nano-diamond and wash it repeatedly with deionized water until neutral to obtain acidification nanodiamond.

[0046] b. Take 200g of ball milling beads with a diameter of 0.02-0.03mm and put them into a ball milling jar with a volume of 50ml, add 0.2g of acidified nano-diamond and 20ml of deionized water, set the speed of the ball mill to 650r / min, and the milling time to 6h , ball milling at room temperature to obtain the initial dispersion of nano-diamond aqueous solution.

[0047] c. Add 60ml of deionized water to the taken out ball milling beads and nano-diamond aqueous solution for ultrasonication. The power is 800W, and the ultrasonication time is 3h.

[0048] d. Take out the nano-diamond aqueous solution after ultrasonication and let it stand for one night...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com