High-performance permanent magnetic ferrite and manufacturing method thereof

A technology for permanent ferrite and its manufacturing method, which is applied in the field of magnetic materials, can solve the problems of demagnetization and low squareness of SrCaLaCo ferrite, and achieve the effects of improving squareness, appropriate grain size, and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

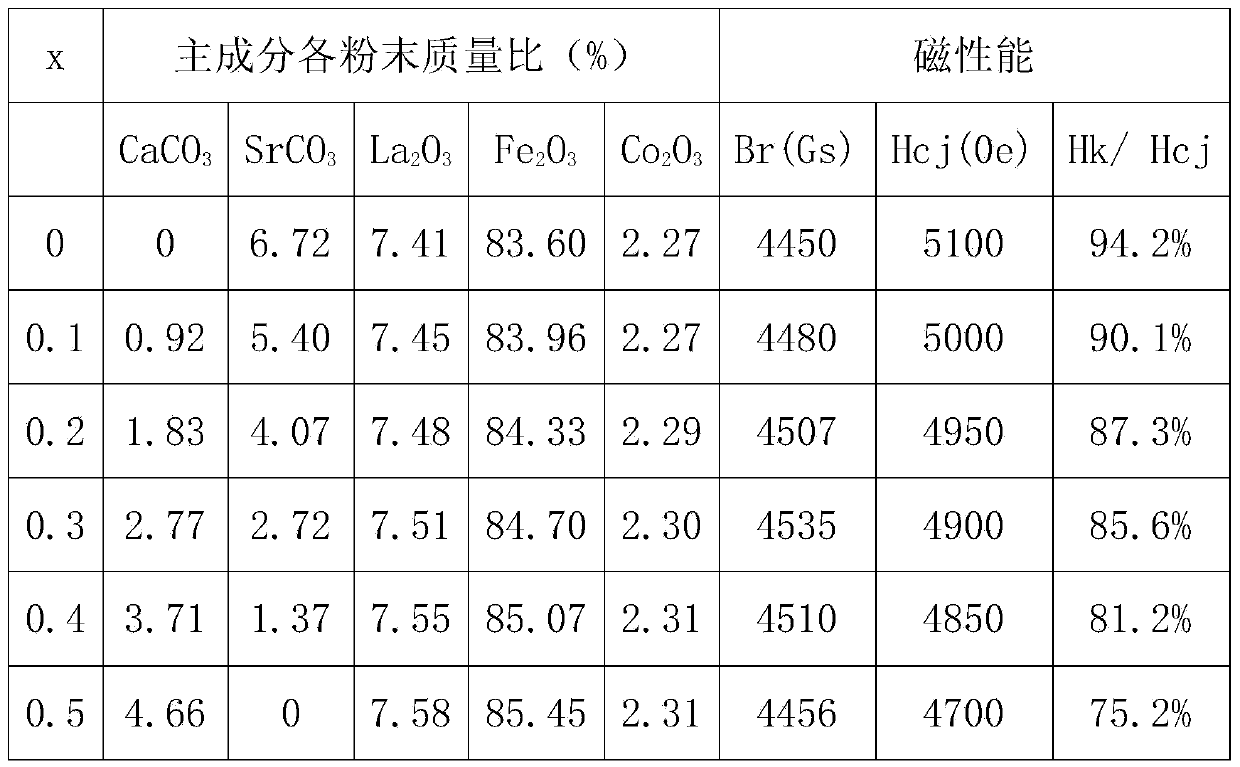

Embodiment 1

[0037] Will Fe 2 o 3 Powder, CaCO 3 Powder, La 2 o 3 Powder, Co 2 o 3 powder, SrCO 3 Powders, all of which have a particle size of less than 5 μm and have the formula Sr 0.5-x Ca x La 0.5 (Fe 11.5 co 0.3 )O 19 The composition of the mixture; after ball milling, drying and sintering in a spark plasma sintering furnace, the sintering temperature is 1350 °C, the heating rate is 100 °C / min, and the holding time is 0.1 hour; after pre-calcination, it is crushed into an average particle size of 3-5 μm. burning material.

[0038] Weigh 450g pre-fired material, add H 3 BO 3 , graphene, nano silicon carbide, Co 2 o 3 , Calcium gluconate, add 650ml of water, carry out secondary ball milling for 20 hours, and add CaCO 3 hours before discharge 3 , SiO 2 , to obtain a slurry with an average particle size of 0.5 μm; when the slurry is dehydrated to a moisture content of 30-40%, it is molded in a magnetic field of 120000e, and the diameter of the formed body is 8cm, and the...

Embodiment 2

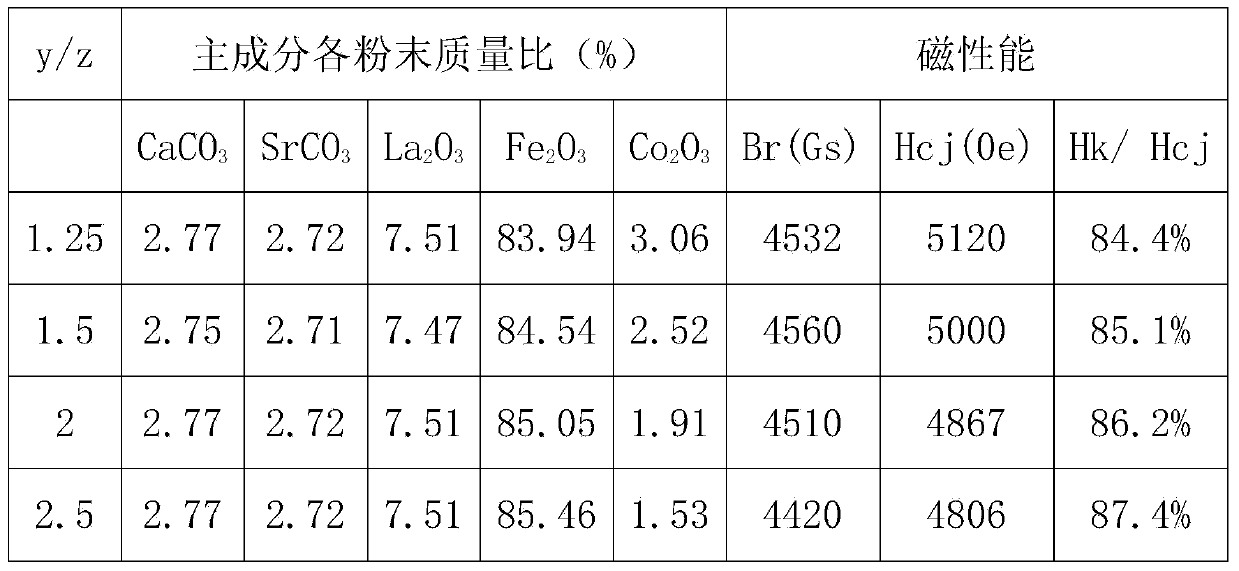

[0044] Will Fe 2 o 3 Powder, CaCO 3 Powder, La 2 o 3 Powder, Co 2 o 3 powder, SrCO 3 Powders, all of which have a particle size of less than 5 μm and have the formula Sr 0.2 Ca 0.3 La 0.5 (Fe 11.8-z co z )O 19 The composition of the mixture; after one ball milling, drying and sintering in a spark plasma sintering furnace, the sintering temperature is 1150°C, the heating rate is 100°C / min, and the holding time is 3 hours. After calcining, it is crushed into a calcined material with an average particle size of 3-5 μm.

[0045] Weigh 450g pre-fired material, add H 3 BO 3 , graphene, nano silicon carbide, Co 2 o 3 , Isomalt, then add 650ml of water, conduct secondary ball milling for 20 hours, and add CaCO 3 hours before discharge 3 , SiO 2 , to obtain a slurry with an average particle size of 0.5 μm; when the slurry is dehydrated to a water content of 30-40%, it is molded in a magnetic field of 120000e, and the diameter of the formed body is 8cm, and the height ...

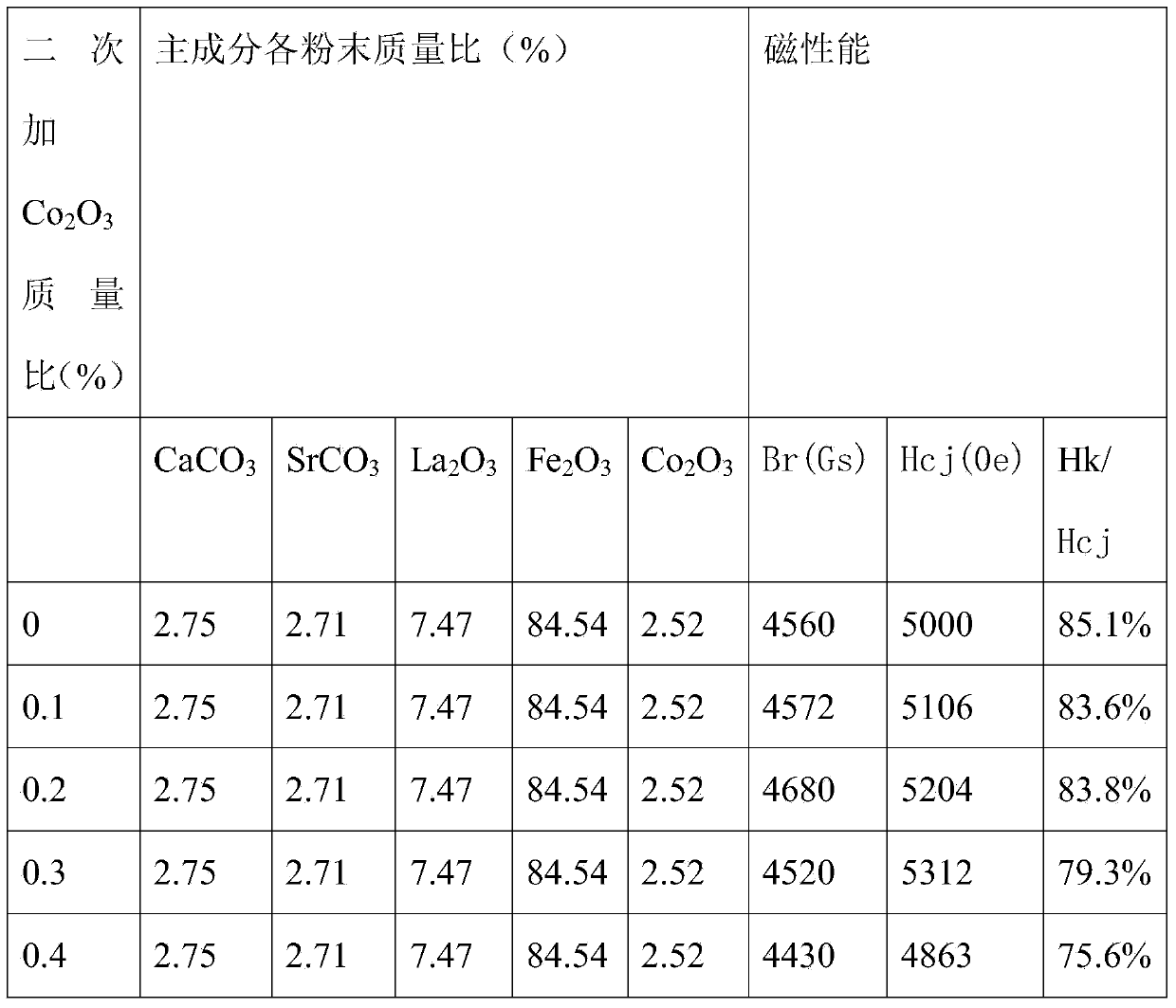

Embodiment 3

[0051] Will Fe 2 o 3 Powder, CaCO 3 Powder, La 2 o 3 Powder, Co 2 o 3 powder, SrCO 3 Powders, all of which have a particle size of less than 5 μm and have the formula Sr 0.2 Ca 0.3 La 0.5 (Fe 11.47 co 0.33 )O 19 The composition of the mixture; after ball milling, drying and sintering in a spark plasma sintering furnace, the sintering temperature is 1120°C, the heating rate is 100°C / min, and the holding time is 2 hours; after pre-sintering, it is crushed into an average particle size of 3-5 μm. burning material.

[0052] Weigh 450g pre-fired material, add H 3 BO 3 , graphene, nano silicon carbide, Co 2 o 3 , erythritol, sorbitol, then add 650ml of water, carry out secondary ball milling for 20h, and add CaCO 3 , SiO 2 , to obtain a slurry with an average particle size of 0.5 μm; when the slurry is dehydrated to a moisture content of 30-40%, it is molded in a magnetic field of 12000Oe, and the diameter of the formed body is 8cm, and the height is 3cm; the green...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com