Method and device for producing diethyl maleate by virtue of rectification and steam osmosis coupling

A technology of diethyl maleate and maleic acid is applied in the field of rectification-steam permeation coupling to produce diethyl maleate, and achieves the effects of reducing production cost, improving dehydration efficiency and high resource recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

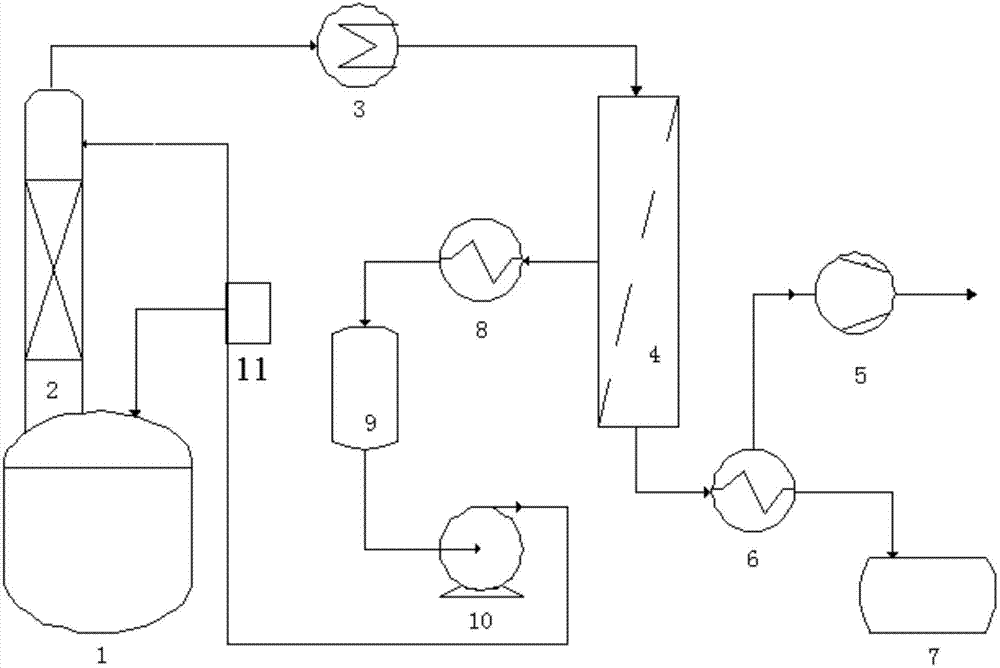

Embodiment 1

[0024] In the reaction kettle, 0.04kg of concentrated sulfuric acid is used as a catalyst, and maleic acid (1.2kg) and absolute ethanol (3L) are subjected to esterification reaction. For preliminary separation, the height of the rectification column is 1m, the diameter of the column is 37mm, and it is filled with 3mm*0.5mm glass spring packing; the heavy component in the rectification column is refluxed to the reactor, and the light component is discharged from the top, which mainly contains ethanol And water, light component steam is reheated to 100°C by a supplementary heater and enters the steam permeable membrane module for dehydration. The membrane module has a membrane area of 0.03m 2 The single-tube NaA molecular sieve membrane module, the permeate side pressure is controlled at 300Pa, and the dehydrated ethanol is returned to the reactor from the top of the rectification column and the top of the reactor respectively. The ratio of ethanol entering the rectification co...

Embodiment 2

[0026] In the reactor, use ferric ammonium sulfate dodecahydrate as catalyst (0.3kg) to carry out esterification reaction of maleic acid (1.2kg) and absolute ethanol (3L), the temperature in the reactor is 120°C, the steam generated at the top of the reactor Preliminary separation is carried out through the rectification column. The height of the rectification column is 1m, the diameter of the column is 37mm, and it is filled with 3mm*0.5mm glass spring packing. It mainly contains ethanol and water. The light component steam is heated to 115°C by a supplementary heater and enters the steam permeable membrane module for dehydration. The membrane module has a membrane area of 0.03m 2 The single-tube T-type molecular sieve membrane module, the permeate side pressure is controlled at 300Pa, the dehydrated ethanol is returned to the reactor from the top of the rectification column and the top of the reactor respectively, and the ratio of ethanol entering the rectification column t...

Embodiment 3

[0029] In the reactor, use concentrated sulfuric acid as catalyst (0.4kg) to carry out the esterification reaction of maleic acid (24kg) and absolute ethanol (60L g). Column for preliminary separation, rectification column height 2.5m, column diameter 100mm, packing 6mm×6mm×0.1mm with stainless steel multi-layer rectangular wire mesh packing; heavy components after rectification flow back to the reactor, light components from the top It is discharged, which mainly contains ethanol and water, and the light component steam is reheated to 100°C through the supplementary heater and enters the steam permeation membrane module for dehydration. The membrane module consists of 4 stages of 0.25m 2Tubular NaA molecular sieve membrane modules with membrane area are formed in series, and the permeate side pressure is controlled at 1000Pa. The ethanol after dehydration is returned to the reactor from the top of the rectification column and the top of the reactor respectively, and the ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com