Method utilizing micro-reactor to continuously synthesize amide herbicide

A technology of amide herbicides and microreactors, applied in chemical instruments and methods, preparation of carboxylic acid amides, preparation of organic compounds, etc., can solve the problems of long production cycle, large consumption of lye, low product yield, etc. Achieve the effects of simple production equipment, improved production efficiency, increased yield and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

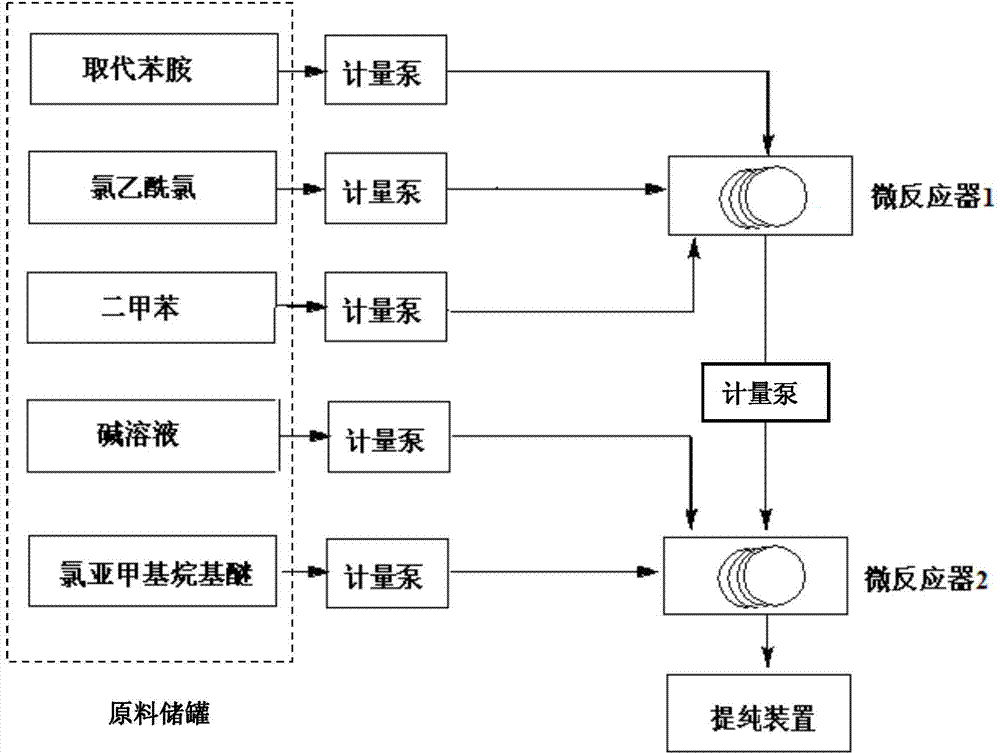

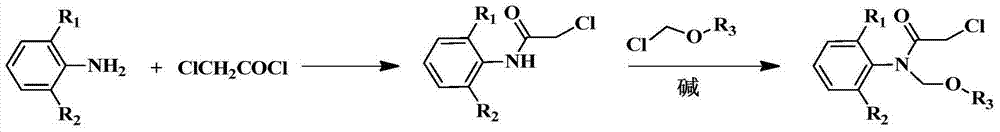

[0031] Inject 2,6-dimethylaniline, chloroacetyl chloride and xylene into micro-reactor 1 with a pore size of 1.5-4 mm through a metering pump for mixed reaction. The reaction temperature is controlled by an external reactor at 50-90 °C, and the reaction stays The time is 6-10 minutes, and the outflowing liquid is chloroacetyl-substituted (2,6-dimethyl)aniline solution.

[0032] Then take the chloroacetyl substituted (2,6-dimethyl) aniline solution, chloromethylene isobutyl ether, and sodium hydroxide solution (50% by mass fraction) prepared by the microreactor 1 and inject the aperture of The mixed reaction is carried out in the microreactor 2 of 0.8-2mm, the reaction temperature is 15-30°C, and the reaction time is 15-40s. Filter the material obtained at the outlet of the microreactor 2, wash the filtrate with an equal volume of water, and recover the solvent under reduced pressure to obtain the finished product of the herbicide ibutachlor. The conversion rate of 2,6-dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com