Lignin-tolerant saccharomyces cerevisiae and application of lignin-tolerant saccharomyces cerevisiae in production of bioethanol

A technology of Saccharomyces cerevisiae and Saccharomyces cerevisiae, which is applied to lignin-tolerant Saccharomyces cerevisiae and its application field in bioethanol production, can solve the problem of low degree of industrial application, low removal rate of toxic components and high processing cost problems, to achieve the effect of promoting industrialization development, improving fermentation efficiency, and strengthening ethanol fermentation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

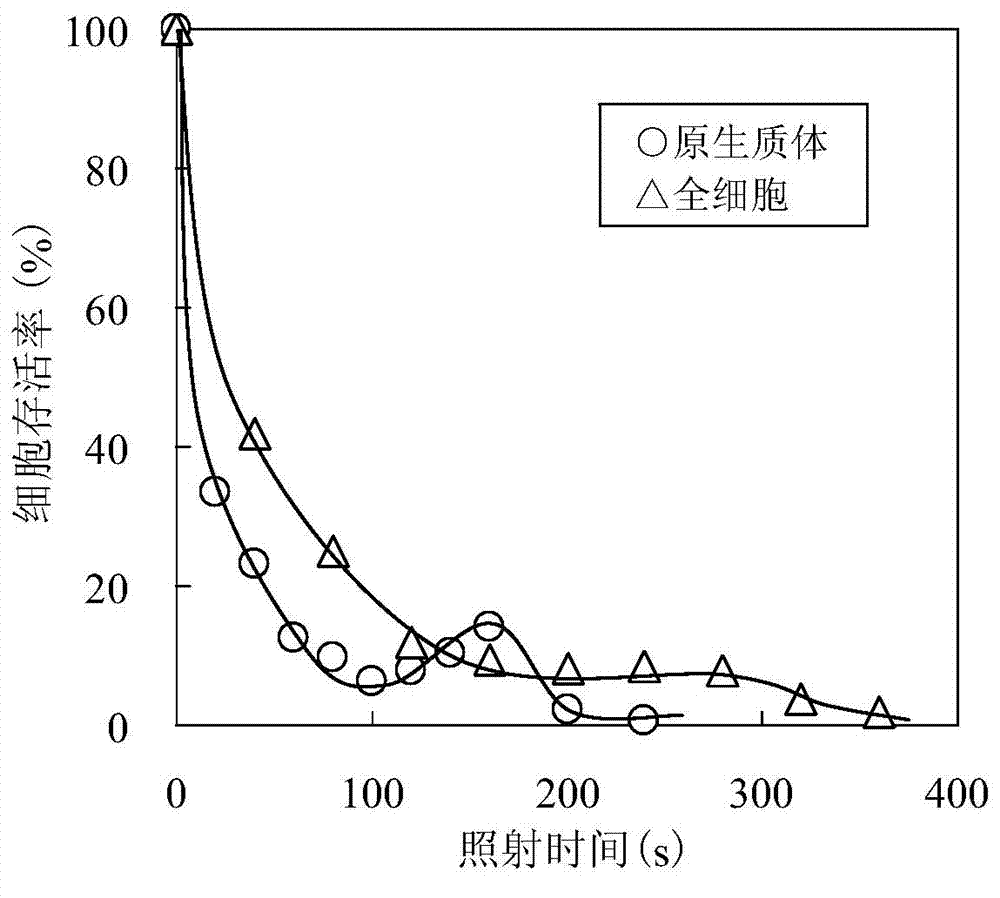

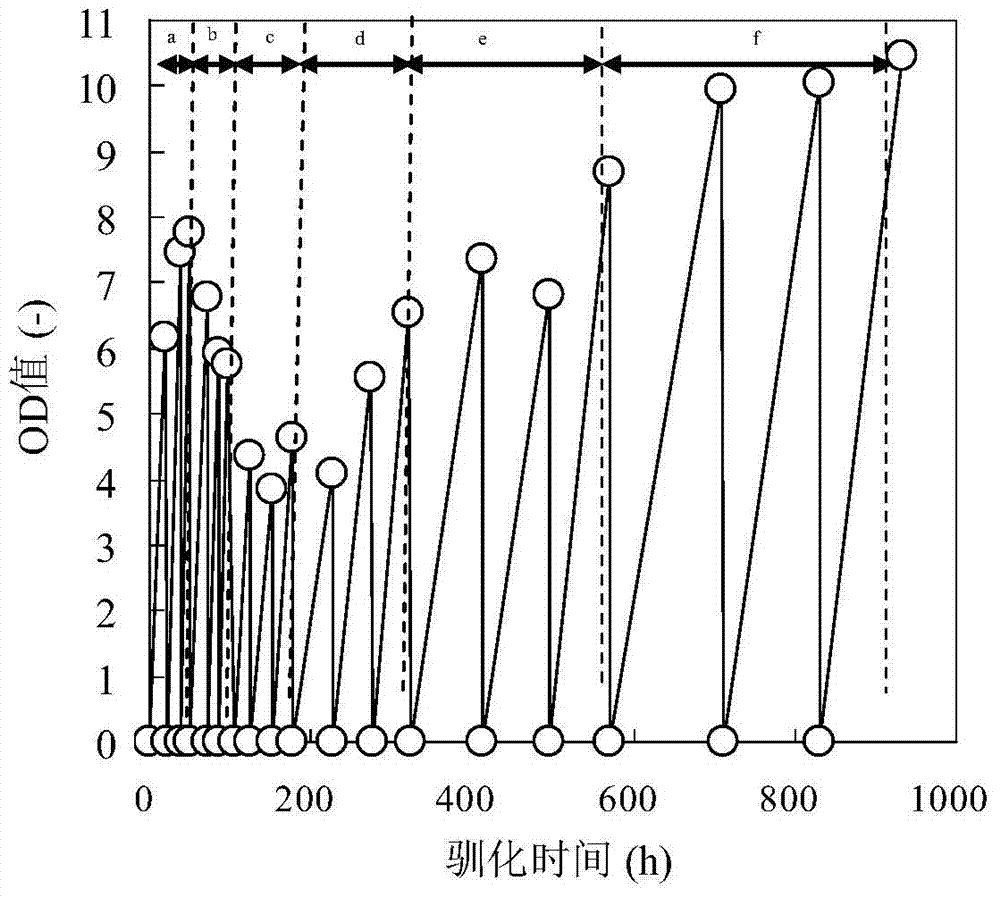

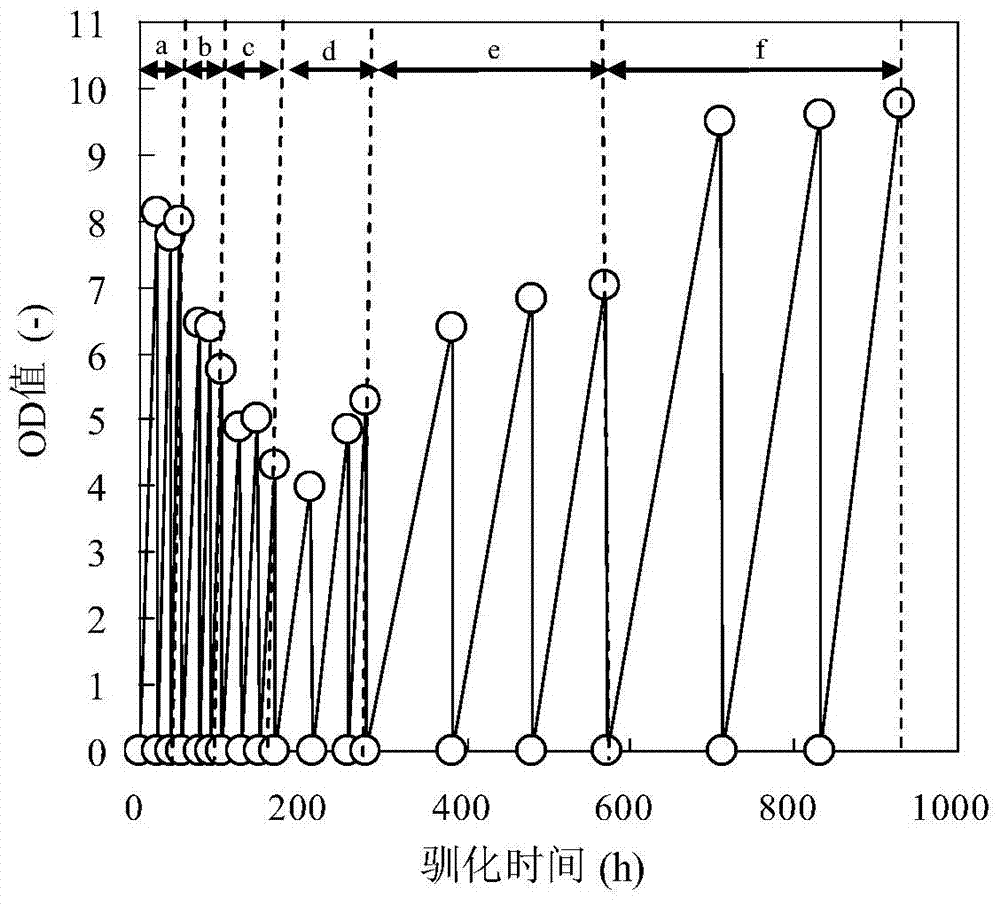

[0030] Example 1 This example illustrates the screening method for Saccharomyces cerevisiae LTY-1 of the present invention.

[0031] The culture medium adopted in the screening of the present invention is:

[0032] (1) Liquid YPD medium: yeast extract powder 10g / L, peptone 20g / L, glucose 20g / L, natural pH.

[0033] (2) Solid YPD medium: 20 g / L of agar was added to the liquid YPD medium.

[0034] (3) Solid regeneration medium: 20 g / L of agar and 170 g / L of sucrose were added to the liquid YPD medium.

[0035] (4) Seed medium: yeast extract powder 10g / L, peptone 20g / L, glucose 20g / L, natural pH.

[0036] (5) Fermentation medium: yeast extract powder 61g / L, peptone 10g / L, glucose 350g / L, natural pH.

[0037] Saccharomyces cerevisiae (Saccharomyces cerevisiae) CGMCC2.1429 (China General Microorganism Collection Center) was used as the original yeast species. After the strains were purchased, they were transferred from the ampoule tube to the slant-plane YPD medium, cultured in...

Embodiment 2

[0061] Example 2 This example illustrates the ethanol fermentation ability of Saccharomyces cerevisiae LTY-1 under different conditions of initial sugar concentration, fermentation time, fermentation temperature and shaker speed.

[0062] 1) Yeast strain

[0063] (1) Original yeast strain (Saccharomyces cerevisiae) CGMCC2.1429: provided by China Microorganism Culture Collection and Management Center.

[0064] (2) Lignin-tolerant Saccharomyces cerevisiae LTY-1: cultivated by the present inventors.

[0065] 2) Medium

[0066] (1) Seed medium: yeast extract powder 10g / L, peptone 20g / L, glucose 20g / L, natural pH.

[0067] 3) Determination of the growth curve of Saccharomyces cerevisiae LTY-1

[0068] A 250mL conical flask was used to aliquot 50mL of seed medium, and Saccharomyces cerevisiae LTY-1 was transferred from the slant YPD medium to the seed medium respectively, and cultured at 30°C and 180rpm for 48h. During the cultivation process, take out one Erlenmeyer flask every...

Embodiment 3

[0079] Example 3 This example illustrates the ethanol fermentation ability of Saccharomyces cerevisiae LTY-I in a lignin-containing fermentation medium.

[0080] 1) Yeast strain

[0081] (1) Original yeast strain (Saccharomyces cerevisiae) CGMCC2.1429: provided by China Microorganism Culture Collection and Management Center.

[0082] (2) Lignin-tolerant Saccharomyces cerevisiae LTY-1: cultivated by the present inventors.

[0083] 2) Medium

[0084] (1) Seed medium: yeast extract powder 10g / L, peptone 20g / L, glucose 20g / L, natural pH.

[0085] (2) Lignin fermentation medium: yeast extract powder 61g / L, peptone 10g / L, glucose 242g / L, syringol 1.44g / L, p-hydroxybenzaldehyde 1.44g / L, vanillin 1.44g / L, pH5.5.

[0086] 3) Ethanol fermentation

[0087] Seed culture: Saccharomyces cerevisiae LTY-1 was cultured to the mid-logarithmic phase under the conditions of seed medium, 30° C., and 180 rpm, and used as seed liquid.

[0088] Ethanol fermentation: the seed liquid was transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com