Aluminum-silicon alloy material and preparation method thereof

An aluminum-silicon alloy and alloy technology, applied in the field of aluminum-silicon alloy materials and their preparation, can solve problems such as high solid solubility and lower alloy conductivity, and achieve the effects of increasing conductivity, reducing porosity, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

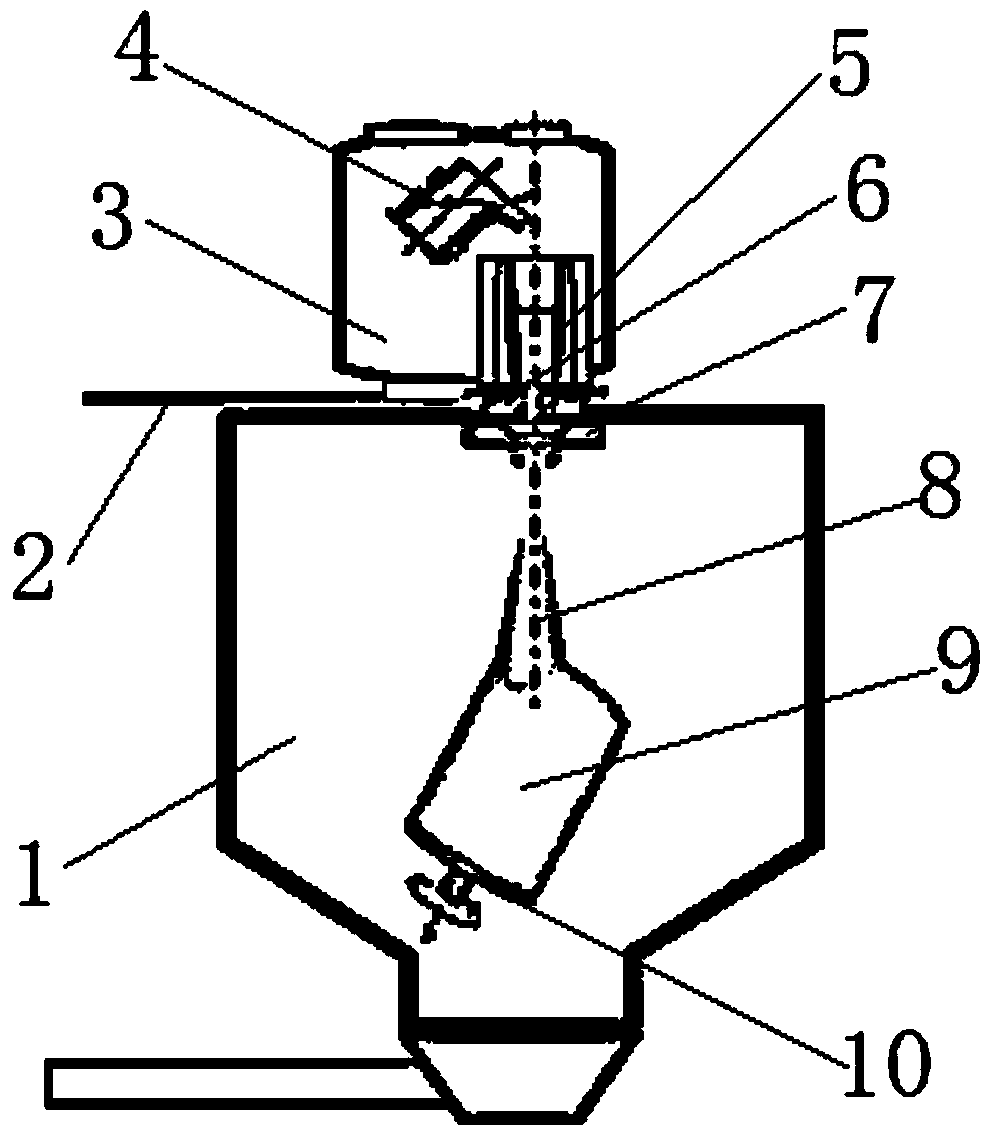

Method used

Image

Examples

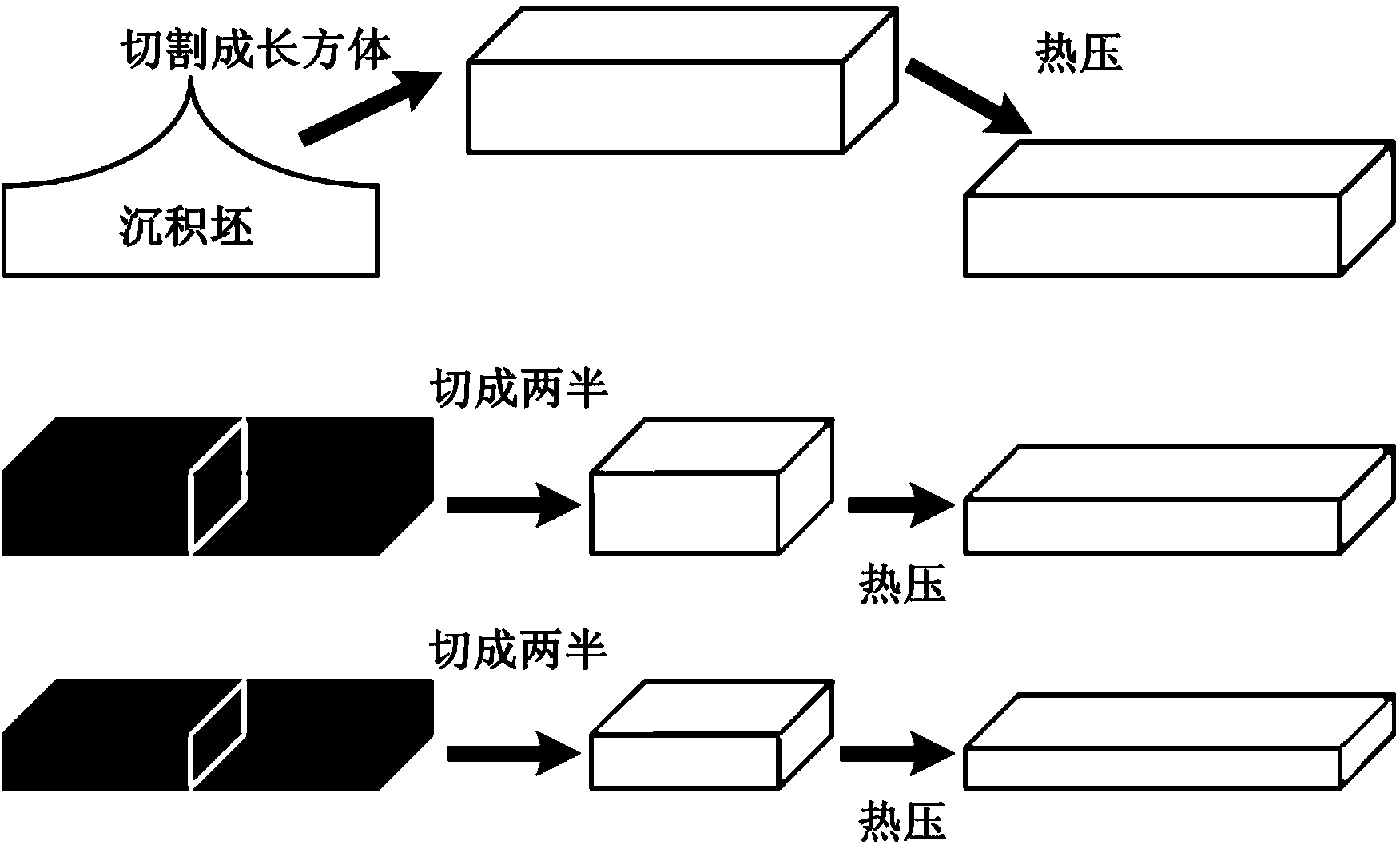

Embodiment 1

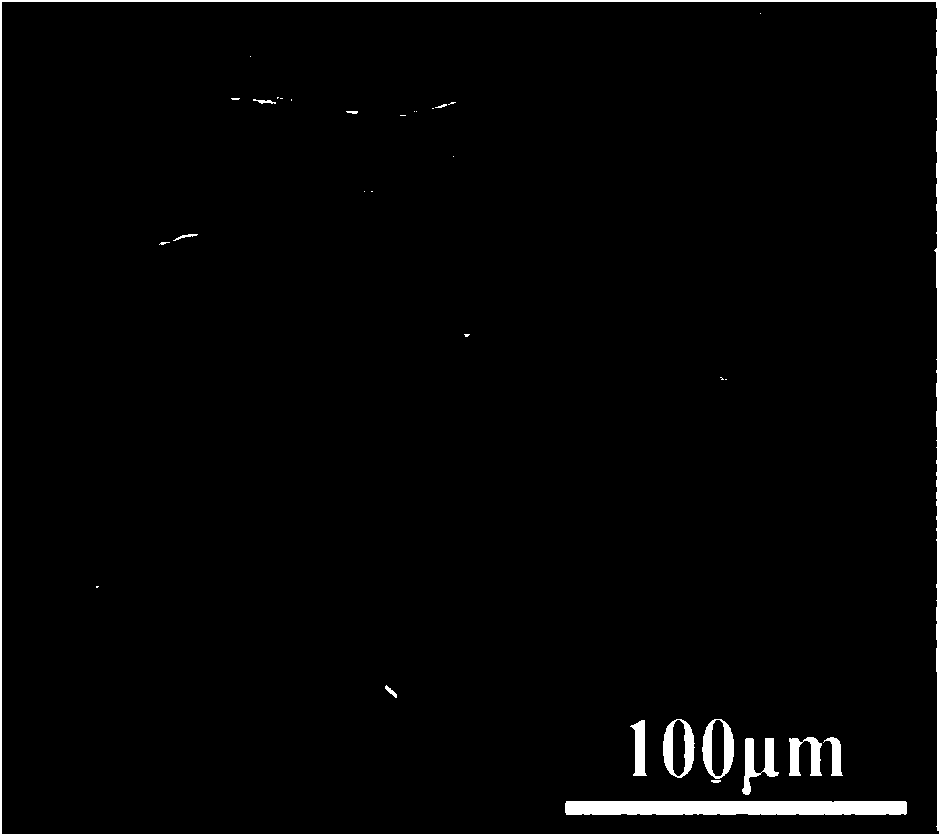

[0035] The pure aluminum ingots with a purity of not less than 99.5wt%, pure silicon and massive lanthanum-cerium mixed rare earths were formulated as Al-20Si-0.2RE to prepare the composition of the master alloy sample, with a total of 5 kg. Since Si has a high melting point and is easy to float above the Al liquid, the bulk Si is broken into small particles with a diameter of about 10-30mm before smelting. After the pure aluminum is completely melted, pure silicon is added several times, and the alloy melt is stirred repeatedly to ensure that the Si floating on the upper layer of the Al liquid is melted and evenly distributed. After the Al and Si are completely melted, the mixed rare earth is added in the form of a block, and the electromagnetic stirring is evenly mixed, and then poured into the sand precision mold, cooled to room temperature, and demolded to obtain the cast Al-20Si-0.2RE alloy sample, SEM Backscattered images such as image 3 shown. The alloy ingots obtain...

Embodiment 2

[0052] The pure aluminum ingots with a purity of not less than 99.5wt%, pure silicon and massive lanthanum-cerium mixed rare earths were formulated as Al-20Si-0.35RE to prepare the composition of the master alloy sample, totaling 5 kg. Since Si has a high melting point and is easy to float above the Al liquid, the bulk Si is broken into small particles with a diameter of about 10-30mm before smelting. After the pure aluminum is completely melted, pure silicon is added several times, and the alloy melt is stirred repeatedly to ensure that the Si floating on the upper layer of the Al liquid is melted and evenly distributed. After the Al and Si are completely melted, the mixed rare earth is added in the form of lumps, and mixed evenly by electromagnetic stirring, and then poured into a sand precision mold, cooled to room temperature, and demolded to obtain a cast Al-20Si-0.35RE alloy sample. The alloy ingots obtained by smelting are broken, and the broken block alloys are placed ...

Embodiment 3

[0062]The pure aluminum ingots with a purity of not less than 99.5wt%, pure silicon and massive lanthanum-cerium mixed rare earths were formulated as Al-20Si-0.5RE to prepare the composition of the master alloy sample, with a total of 5 kg. Since Si has a high melting point and is easy to float above the Al liquid, the bulk Si is broken into small particles with a diameter of about 10-30mm before smelting. After the pure aluminum is completely melted, pure silicon is added several times, and the alloy melt is stirred repeatedly to ensure that the Si floating on the upper layer of the Al liquid is melted and evenly distributed. After the Al and Si are completely melted, the mixed rare earth is added in the form of lumps, and mixed evenly by electromagnetic stirring, and then poured into a sand precision mold, cooled to room temperature, and demolded to obtain a cast Al-20Si-0.5RE alloy sample. The alloy ingots obtained by smelting are broken, and the broken block alloys are pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap