A tissue controllable high aluminum content cu-al 2 o 3 Preparation Technology of Nano-dispersed Copper Alloy

A cu-al2o3, preparation process technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of alloy plastic toughness and impact resistance reduction, and achieve the effect of excellent performance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

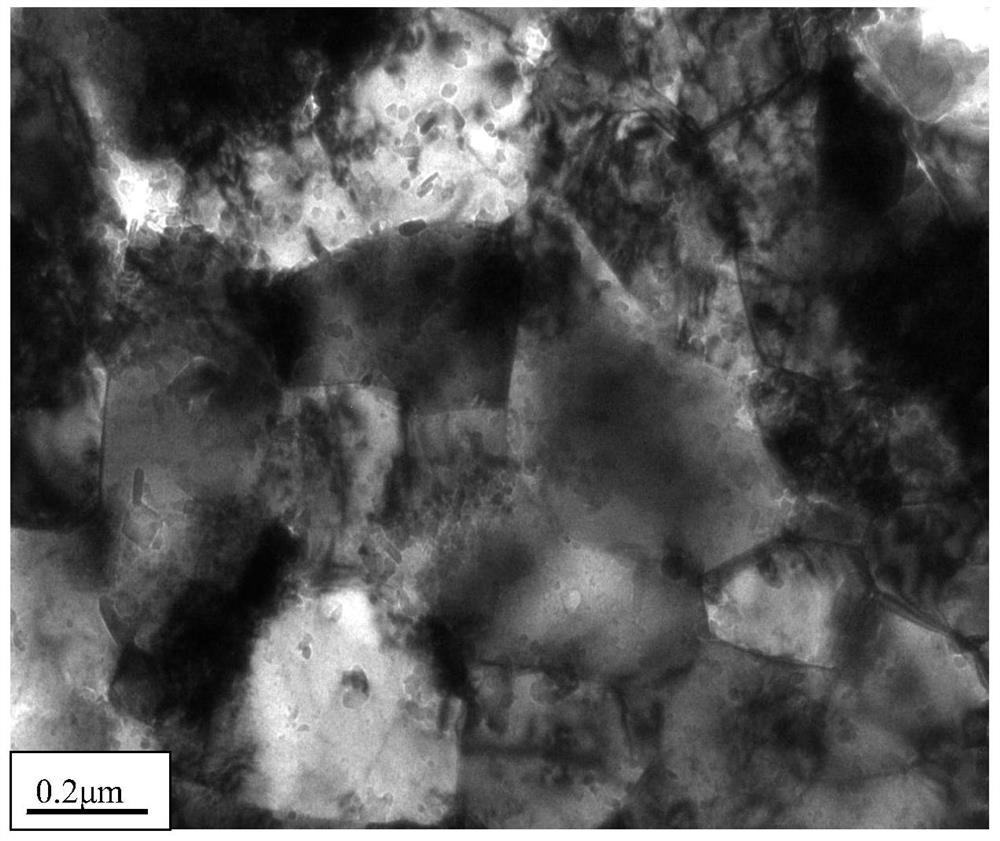

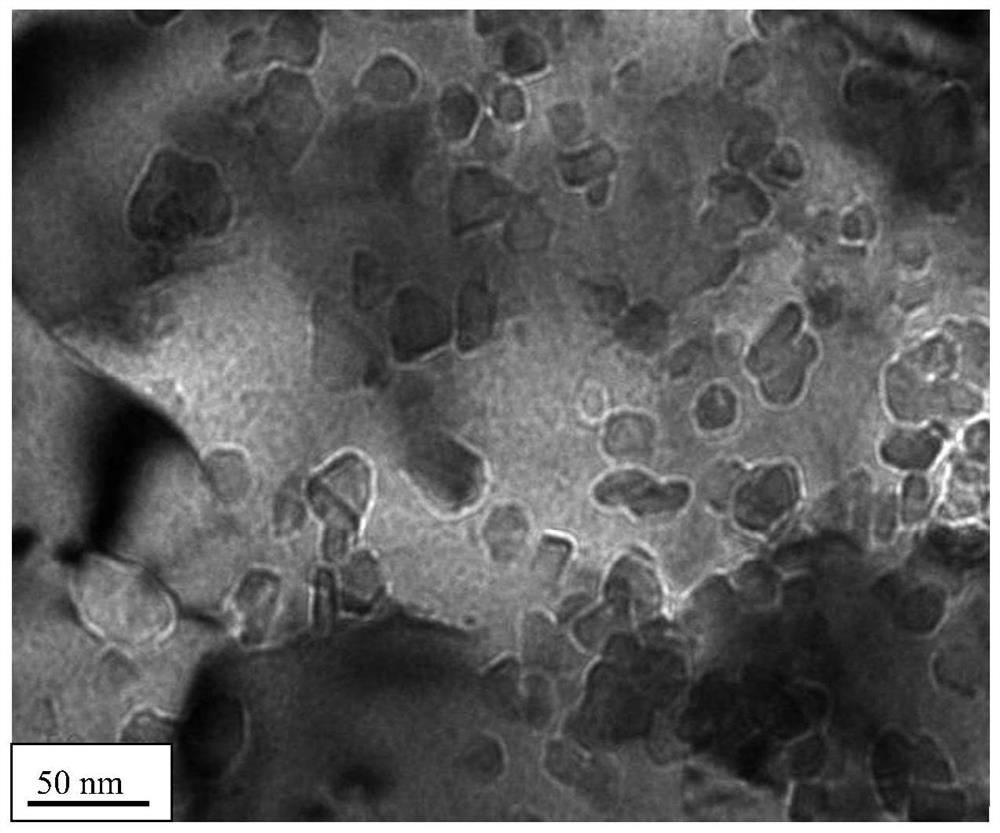

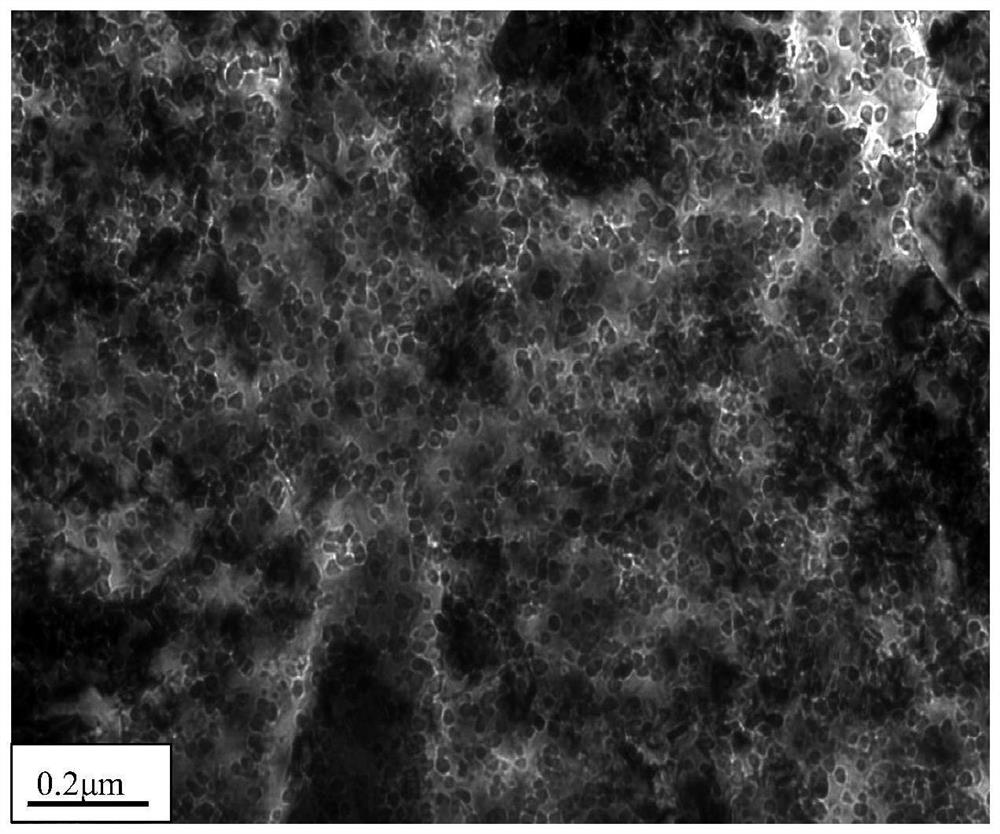

[0050] Al and Cu are smelted at 1200-1230°C to form a Cu-Al alloy melt with an Al content of 0.6wt%. After the melt is purified and impurity removed, high-purity nitrogen is used (the purity of nitrogen is not less than 99.99%) Atomization prepares alloy powder, sieves out particle diameter and is less than 40 mesh alloy powder, it is mixed with oxidant (Cu 2 O) mixing, the amount of oxidant added accounted for 4.8% of the alloy powder mass, the mixture was ball milled for 3 hours, the ball to material ratio was 5:1, the ball milling speed was 200rpm, and the atmosphere was air. Heat the ball-milled material to 380°C in an argon atmosphere and keep it warm for 3 hours to internally oxidize the ball-milled activated alloy powder and oxidant, then continue to heat to 900°C for 3 hours to oxidize and crush until the powder mesh is less than 40 mesh. ℃Hydrogen reduction for 4 hours, cold isostatic pressing of the billet, the argon chamber is wrapped in a pure copper sheath, and th...

Embodiment 2

[0055] Al and Cu are smelted at 1200-1230°C to form a Cu-Al alloy melt with an Al content of 0.8wt%. After the melt is purified and impurity removed, it is prepared by atomizing with high-purity nitrogen (nitrogen purity 99.99%) Alloy powder, sieve the alloy powder with particle size less than 40 mesh, and mix it with oxidant (Cu 2 O) mixing, the amount of oxidant added accounted for 6.36% of the alloy powder mass, the mixture was ball milled for 4 hours, the ball-to-material ratio was 7:1, the ball milling speed was 200rpm, and the atmosphere was air. Heat the ball-milled material to 400°C in an argon atmosphere and keep it warm for 3 hours to internally oxidize the ball-milled activated alloy powder and the oxidizing agent, then continue to heat to 900°C for 3.5 hours to internally oxidize, and crush the powder until the mesh size is less than 40 mesh. Hydrogen reduction at 900°C for 4 hours, cold isostatic pressing of the billet, wrapping in the argon chamber in a pure copp...

Embodiment 3

[0060] Al and Cu are smelted at 1200-1230°C to form a Cu-Al alloy melt with an Al content of 1.0wt%. After the melt is purified and impurity removed, it is atomized with high-purity nitrogen (nitrogen purity 99.99%) Prepare the alloy powder, sieve out the alloy powder with particle size less than 40 mesh, and mix it with oxidant (Cu 2 O) Mixing, the amount of oxidant added accounted for 8% of the alloy powder mass, the mixture was ball milled for 5 hours, the ball to material ratio was 7:1, the ball milling speed was 250rpm, and the atmosphere was air. Heat the argon ball milled material to 400°C in a nitrogen atmosphere and keep it warm for 3.5 hours to internally oxidize the ball-milled activated alloy powder and the oxidant, then continue to heat to 900°C for 4 hours to internally oxidize, and crush the powder until the mesh size is less than 40 mesh. ℃Hydrogen reduction for 4 hours, cold isostatic pressing of the billet, the argon chamber is wrapped in a pure copper sheath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com