Shale Oil Sludge Treatment Process

A treatment process, shale oil technology, applied in sludge treatment, water/sludge/sewage treatment, hydrocarbon oil treatment, etc., can solve the problems of secondary pollution, volatile, large addition ratio, etc., to avoid link pollution , Economic benefit and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

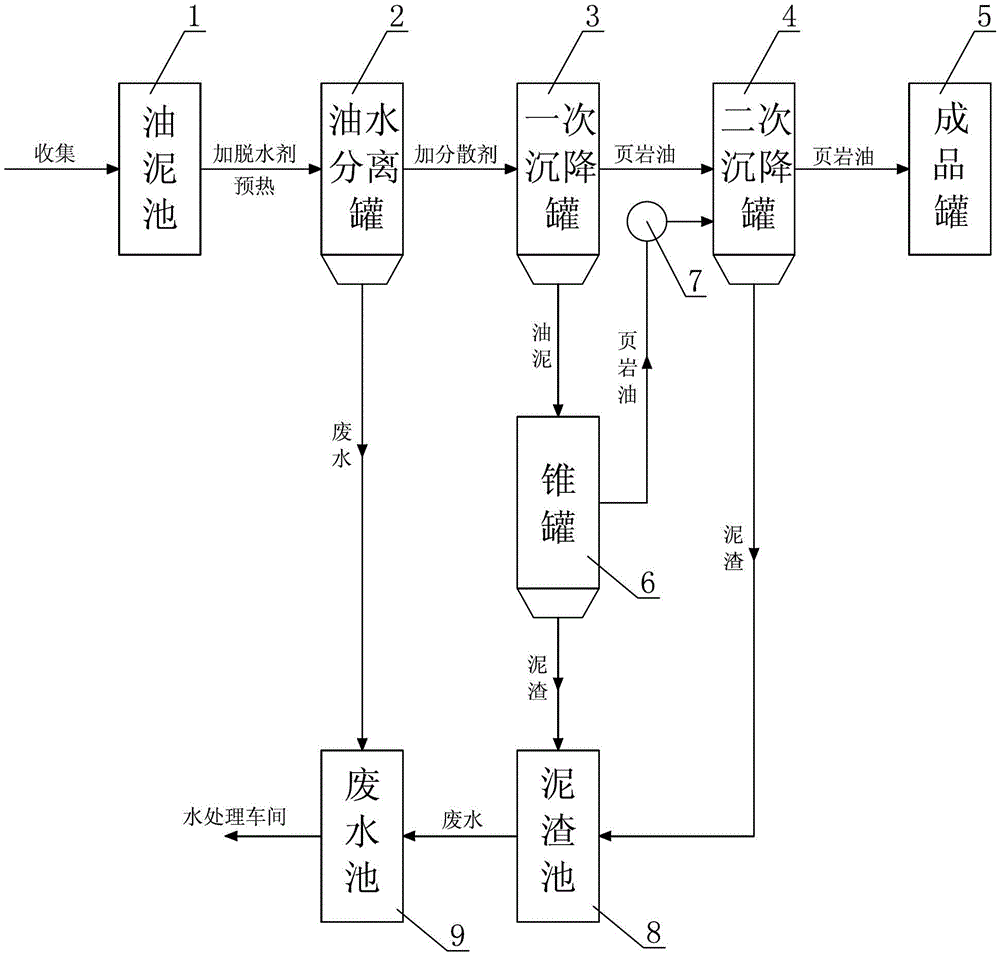

[0016] Such as figure 1 As shown, the shale oil sludge treatment process of the present invention comprises the following steps:

[0017] (1) The sludge raw materials containing shale oil produced in the production process and maintenance of the factory, cleaning tanks, high concentration tanks, water treatment workshops, etc. are collected in a unified manner into the sludge pool 1, and the shale sludge raw materials in the sludge pool 1 are collected After being heated to 40-50°C, it is transported to the oil-water separation tank 2;

[0018] (2) Continue to heat the shale oil sludge raw material in the oil-water separation tank 2 to 70-90°C, add a dehydrating agent to carry out preliminary oil-water separation treatment on the shale oil sludge raw material, so that the moisture can be removed to 30%-40%, and the The waste water in the waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com