Preparation method of novel medicinal transdermal penetration enhancer

A permeation enhancer, a new type of technology, applied in the field of preparation of new medicinal transdermal permeation enhancers, can solve the problems of limited penetration enhancement effect of macromolecular drugs and failure to achieve the penetration enhancement effect, and achieve long service life and low corrosion , high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

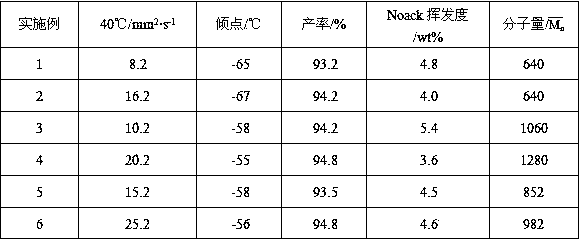

Examples

Embodiment 1

[0019] (1) Preparation of active catalyst: In a vacuum glove box, 1, 3-dimethylimidazole was mixed with TiCl 4 Mix the reaction under dichloromethane, and control the intensity of the reaction by stirring, wherein, satisfy n(1,3-dimethylimidazole): n(TiCl 3 ) = 1 : 2, the reaction temperature is controlled at 45°C, and the reaction time is 2 hours to obtain an active catalyst.

[0020] (2) Preparation of liquid polyolefin: firstly, the 2 L high-pressure reactor was dried, vacuumed, and nitrogen-filled to ensure that the inside of the reactor was inert gas to protect the environment. Next, add to the reactor = 480 HBPE and decene (C 10 ), the active catalyst system and methylene chloride, satisfying n(HBPE): n(C 10 ) = 1 : 0.35, V (HBPE + C 10 ): V (catalyst): V (organic solvent) = 5 : 0.5: 20, at 280 r min -1 Stir to make it fully contact, keep the pressure in the kettle at 0.6 MPa, the temperature at 55°C, and control the reaction time at 8 hours to obtain the primary p...

Embodiment 2

[0023] (1) Preparation of active catalyst: In a vacuum glove box, 1-methyl-3-ethylimidazole was mixed with AlCl 3 Mix the reaction under cyclohexane, and control the intensity of the reaction by stirring, wherein, satisfy n(1-methyl-3-ethylimidazole): n(AlCl 3 ) = 1 : 4, the reaction temperature was controlled at 30°C, and the reaction time was 4 hours to obtain an active catalyst.

[0024] (2) Preparation of liquid polyolefin: firstly, the 2 L high-pressure reactor was dried, vacuumed, and nitrogen-filled to ensure that the inside of the reactor was inert gas to protect the environment. Next, add to the reactor = 390 for HBPE and octene (C 8 ), active catalyst system and organic solvent, satisfying n(HBPE): n(C 8 ) = 1 : 0.45, V (HBPE + C 8 ): V (catalyst): V (cyclohexane) = 8 : 0.8: 44, at 260 r min -1Stir to make it fully contact, keep the pressure in the kettle at 1.5 MPa, the temperature at 35°C, and control the reaction time at 12 hours to obtain the primary produc...

Embodiment 3

[0027] (1) Preparation of active catalyst: In a vacuum glove box, 1-methyl-3-propylimidazole and ZnCl 2 The reaction was mixed under chloroform, and the intensity of the reaction was controlled by stirring, wherein, n(1-methyl-3-propylimidazole): n(ZnCl 2 ) = 1 : 2, the reaction temperature is controlled at 35°C, and the reaction time is 3.5 hours to obtain an active catalyst.

[0028] (2) Preparation of liquid polyolefin: firstly, a 10 L high-pressure reactor was dried, vacuumed, and nitrogen-gassed to ensure that the inside of the reactor was inert gas to protect the environment. Next, add to the reactor = 560 HBPE and octene (C 8 ), the active catalyst system and chloroform, satisfying n(HBPE): n(C 8 ) = 1 : 2.6, V (HBPE + C 8 ): V (catalyst): V (cyclohexane) = 6 : 0.5: 28, at 200 r min -1 Stir to make it fully contact, keep the pressure in the kettle at 2.0 MPa, the temperature at 45°C, and control the reaction time at 6 hours to obtain the primary product of liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com