Pretreatment method for culturing oleaginous microorganisms from degreased silkworm chrysalis residues, product obtained by using pretreatment method and applications of product

A technology of oil-producing microorganisms and pretreatment, applied in the field of biological resources and the environment, to achieve the effects of mild reaction conditions, improved efficiency, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

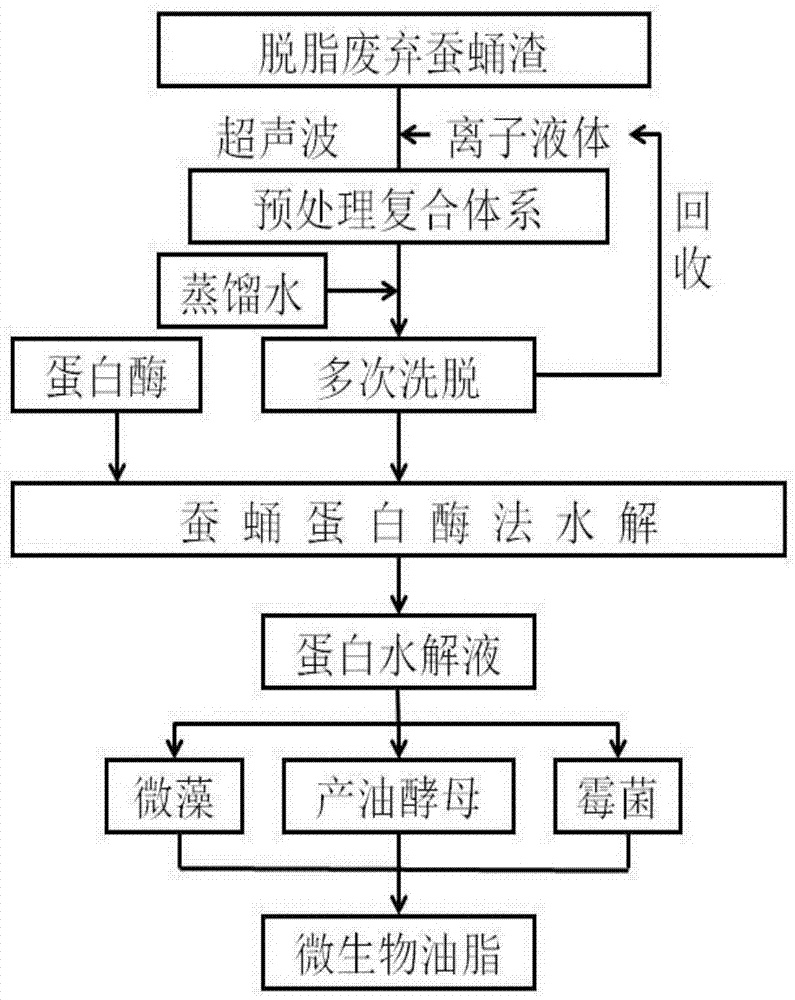

[0022] Embodiment 1 Silkworm chrysalis residue pretreatment

[0023]Weigh 0.5 g of the obtained crude degreased silkworm chrysalis and mix it with 9.5 g of [Bmim]Cl. The ultrasonic power is 150 W, and the reaction temperature is 65 ° C. After 1 h of reaction, elution and centrifugation are performed with a small amount of distilled water several times to remove the ionic liquid. Then add 20mL of water and adjust the pH value to 6.5, then add 0.005g of flavor protease, stir and hydrolyze at 50°C for 60 minutes, and add alkali during the reaction to keep the pH at about 6.5. After the hydrolysis, use a boiling water bath 10min to inactivate the enzyme, centrifuge at 8000r / min for 10min, and take the supernatant. The degree of hydrolysis was measured to be 28.54%.

Embodiment 2

[0024] Embodiment 2 Silkworm chrysalis residue pretreatment

[0025] The thick defatted silkworm chrysalis and 2.8g of [Emim][PF 6 ] mixing, the ultrasonic power is 120W, and the reaction temperature is 60°C. After 1 hour of reaction, elution and centrifugation with a small amount of distilled water are used to remove the ionic liquid. Then add 50mL of water and adjust the pH to 8.0, and add alkali during the reaction to keep the pH at about 8.0, then add 0.015g of trypsin and stir for 90 minutes at 55°C for hydrolysis. After the hydrolysis, use a boiling water bath 10min to inactivate the enzyme, centrifuge at 8000r / min for 10min, and take the supernatant. The degree of hydrolysis was measured to be 26.73%.

Embodiment 3

[0026] Embodiment 3 Silkworm chrysalis residue pretreatment

[0027] The thick defatted silkworm chrysalis and 2g of [Omim][BF 4 ] mixing, the ultrasonic power is 150W, and the reaction temperature is 60°C. After 1 hour of reaction, elution and centrifugation with a small amount of distilled water are used to remove the ionic liquid. Then add 20mL of water and adjust the pH value to 7.0, and add acid or alkali to adjust during the reaction, then add 0.005g of neutral protease and stir at 50°C for 40 minutes for hydrolysis. After the hydrolysis, use a boiling water bath for 10 minutes to treat the enzyme Inactivate, centrifuge at 8000r / min for 10min, and take the supernatant. The degree of hydrolysis was measured to be 23.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com