Method for efficiently and accurately detecting content of silicon dioxide in quartz sand

A technology of silica and high-purity quartz sand, which is used in the preparation of test samples, fluorescence/phosphorescence, material excitation analysis, etc. Cumbersome and other problems, to achieve the effect of uniform and stable melting samples, true and reliable detection results, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment will be described in detail below.

[0025] A method for efficiently and accurately detecting silica content in quartz sand, comprising the following steps:

[0026] A. Burn the 4N-grade quartz sand, then lower the temperature and cool it down, then put it in a weighing bottle and cover it for later use.

[0027] Take about 10g of 4N-grade quartz sand, put it in a cleaned platinum crucible and cover it, put it into a muffle furnace heated to 950°C, burn it for 1h, then take it out and cool it down to 300-400°C, and then put it in a desiccator Cool to room temperature.

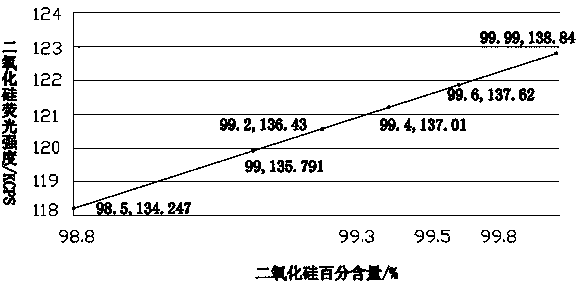

[0028] B. Draw the standard working curve of the percentage content of silicon dioxide:

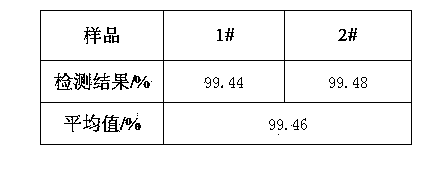

[0029] Weigh the 4N-grade quartz sand obtained in step A as the solute, analyze the pure lithium tetraborate as the solvent to melt a series of standard samples, and use a fluorometer to record the fluorescence intensity values corresponding to the series of standard samples, and then use the silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com