Magnetic metal containing resin, and coil component and electronic component, using same

A technology of magnetic metal and electronic components, applied in the direction of inorganic material magnetism, transformer/inductor magnetic core, etc., can solve the problems of high permeability barrier, low saturation magnetization of ferrite, and decrease in filling volume, etc., and achieve the suppression of magnetic metal Settlement, improvement in thermal shock resistance, and reduction in coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

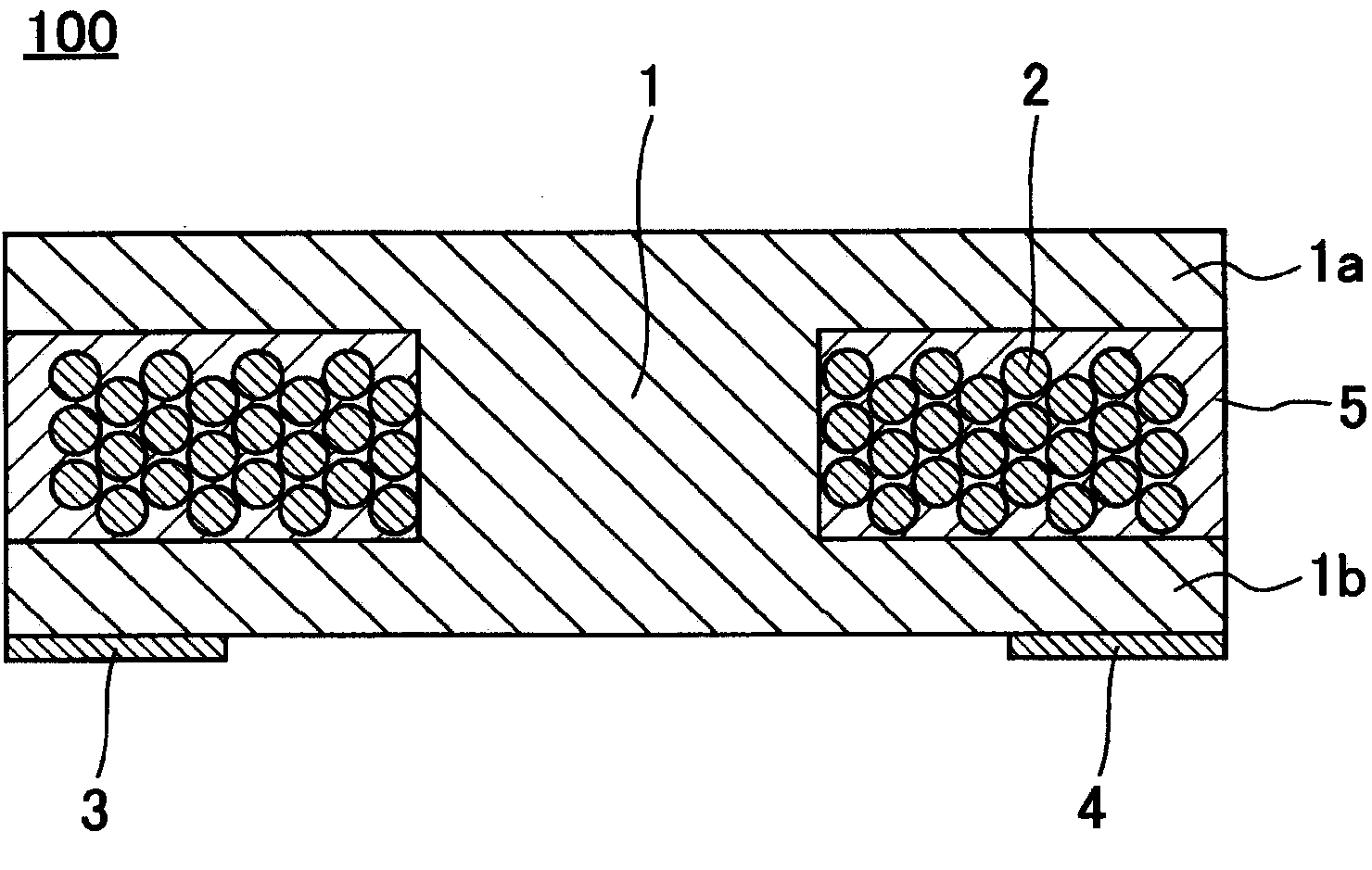

Image

Examples

experiment example 1

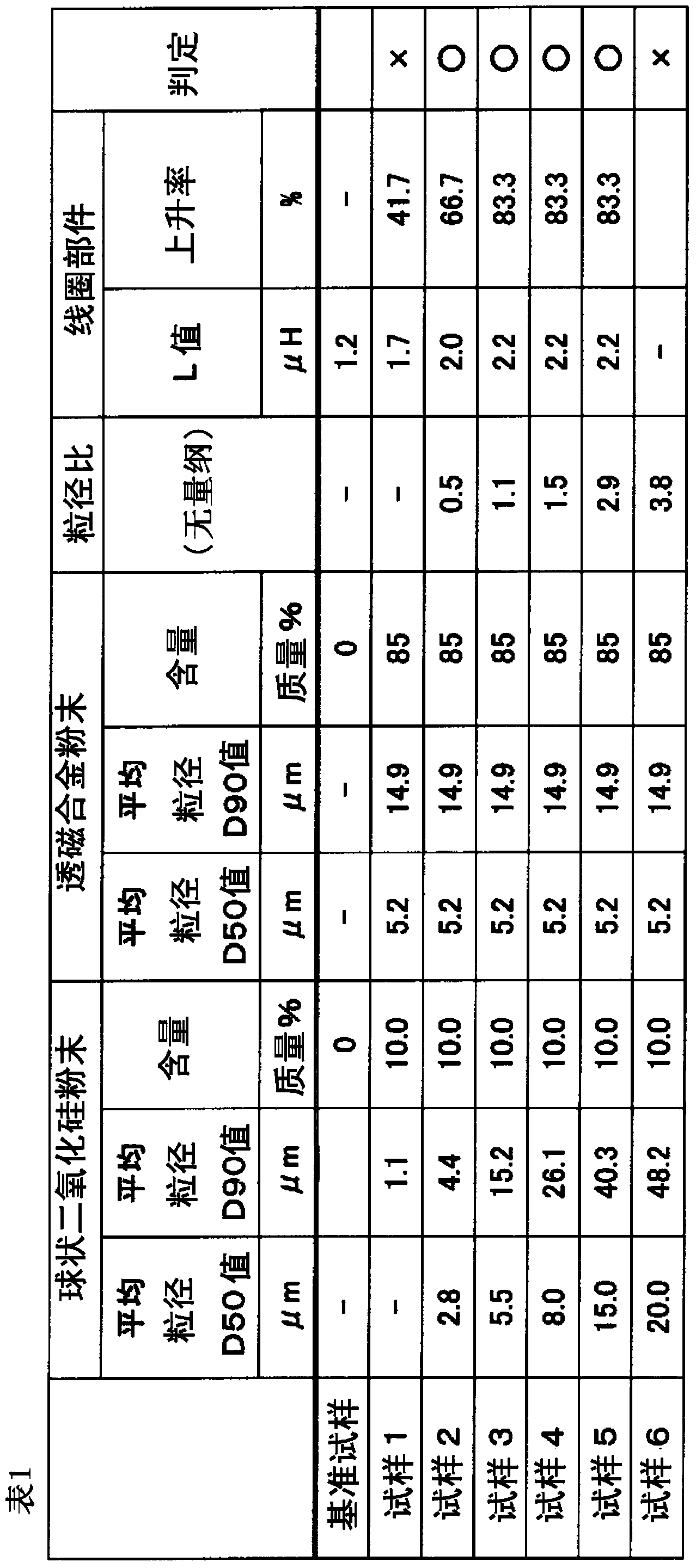

[0052] In Experimental Example 1, Samples 1 to 6 were produced as follows as the magnetic metal-containing resin used for the coil component. In Experimental Example 1, samples in which the average particle diameter of the spherical silica powder was varied were prepared.

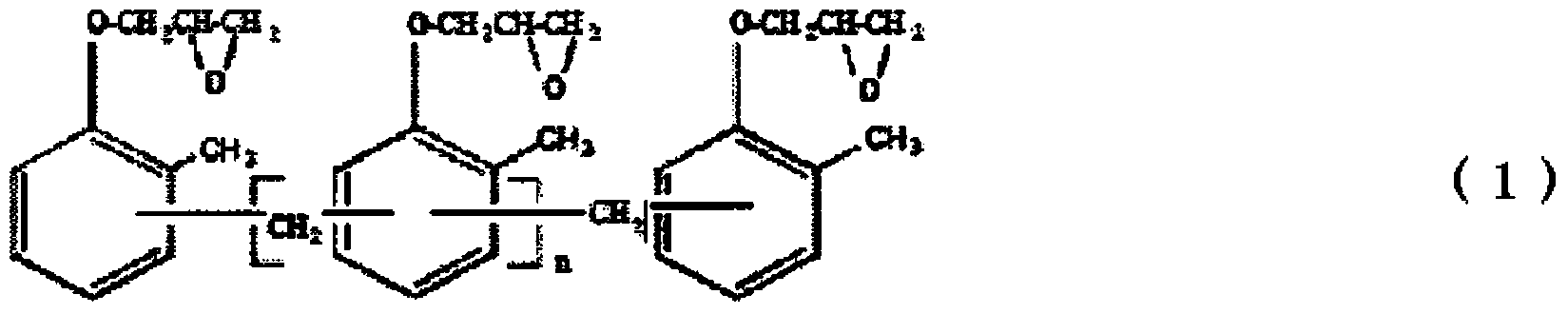

[0053] First, a cresol novolak type epoxy resin was prepared as a resin commonly used in samples 1 to 6. As magnetic metal powder, prepare permalloy powder (Fe-45Ni), as oxide, prepare spherical silica powder (SiO 2 ). Table 1 shows the respective contents of spherical silica powder and permalloy powder contained in each sample prepared in Experimental Example 1, the inductance value of the coil member, and the like.

[0054]

[0055] As shown in Table 1, among the prepared permalloy powders, the permalloy powders of samples 1 to 6 had an average particle diameter D50 value of 5.2 μm and a D90 value of 14.9 μm. In addition, in samples 1 to 6, the content of the permalloy powder was 85% by mass. It sh...

experiment example 2

[0068] Regarding Experimental Example 2, the samples shown below were prepared as the magnetic metal-containing resin used for the coil component. In Experimental Example 2, samples were prepared in which the content of the permalloy powder was changed for the magnetic metal-containing resin.

[0069] First, a cresol novolak type epoxy resin was prepared as a resin commonly used in samples 7 to 12. As the magnetic metal powder, permalloy powder (Fe-45Ni) was prepared. Table 2 shows the respective contents of spherical silica powder and permalloy powder contained in each sample prepared in Experimental Example 2, the inductance value of the coil member, and the like.

[0070]

[0071] As shown in Table 2, among the prepared permalloy powders, any one of the permalloy powders of samples 7 to 12 had an average particle diameter D50 value of 5.2 μm and a D90 value of 14.9 μm. The contents of permalloy powder in sample 7, sample 8, sample 9, sample 10, sample 11 and sample 12 ...

experiment example 3

[0081] Regarding Experimental Example 3, the samples shown below were prepared as the magnetic metal-containing resin used for the coil component. In Experimental Example 3, samples obtained by varying the contents of the permalloy powder and the spherical silica powder were prepared.

[0082] First, a bisphenol A type epoxy resin was prepared as a resin commonly used in samples 13 to 18. As the magnetic metal powder, permalloy powder (Fe-45Ni) was prepared. Table 3 shows the respective contents of the spherical silica powder and the permalloy powder contained in the samples prepared in Experimental Example 3, the properties of the magnetic metal-containing resin, the inductance value of the coil member, and the like.

[0083]

[0084] As shown in Table 3, among the prepared permalloy powders, the average particle diameter D50 value of any of the permalloy powders in sample 13 to sample 18 is 5.2 μm, and the D90 value is 14.9 μm. The contents of permalloy powder in sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com