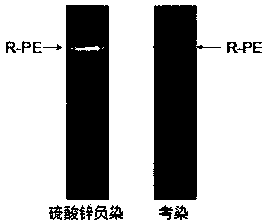

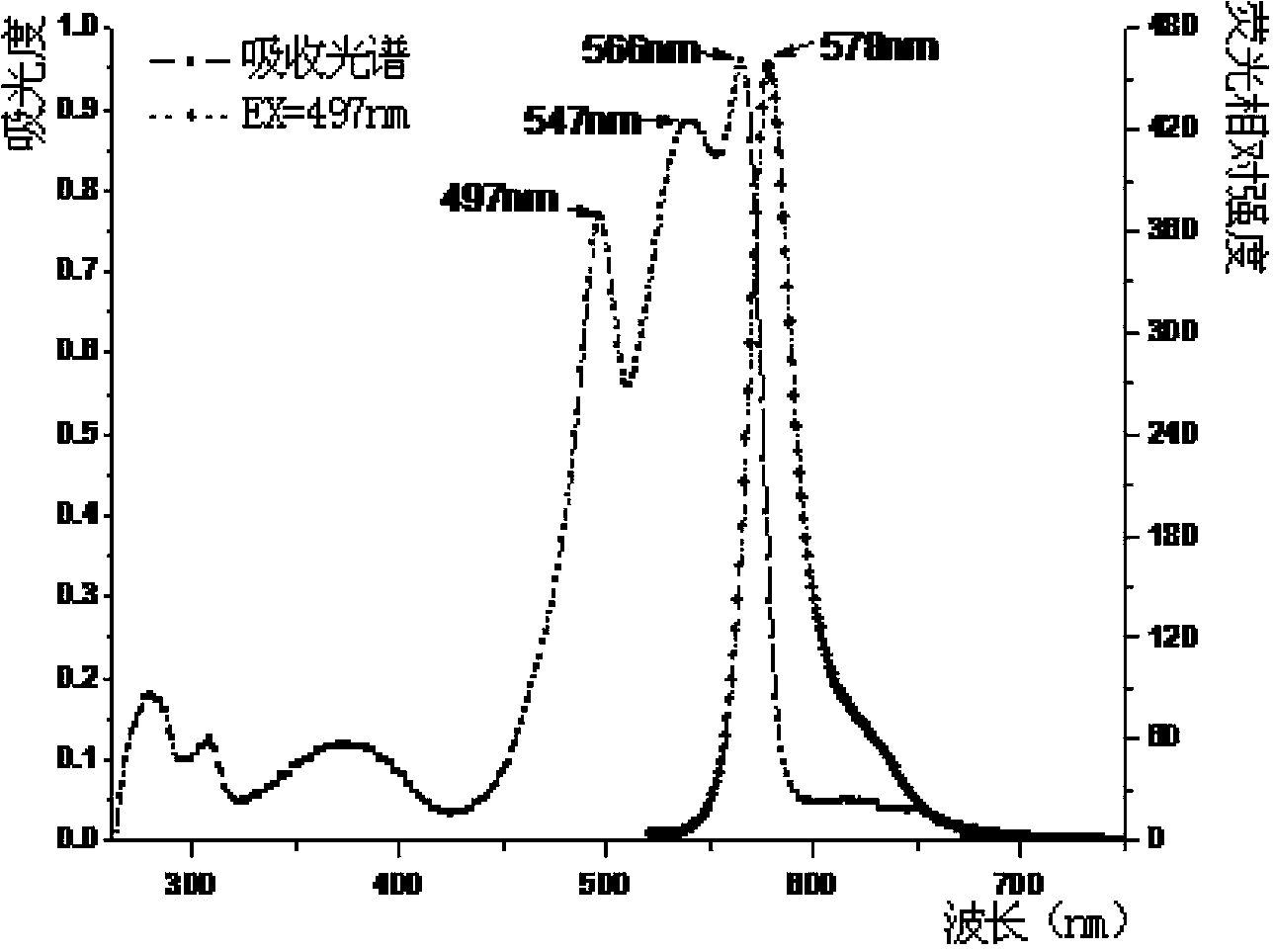

Efficient separation and purification method of Gracilaria verrucosa reagent grade R-phycoerythrin

A technology for separation and purification of phycoerythrin, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of long operation period, high cost, and large output loss, and achieve reduced production costs and simple operation , High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Wash the large economical marine red algae asparagus with deionized water;

[0021] (2) Rough extraction of R-phycoerythrin: Superfine asparagus to a particle size of 0.1-0.5 mm, crush and add 10 times its volume to PBS buffer solution with a pH of 7.0 and a concentration of 50 mM / L, 4 Centrifuge at 15000rpm / min for 30min at 4℃ for 48 hours, then filter the supernatant after centrifugation and concentrate the filtrate with a 50kd concentrator;

[0022] (3) Preliminary purification of R-type phycoerythrin: Add solid ammonium sulfate to the crude phycoerythrin extract obtained in step (2) to make the saturation reach 25%, and then let it stand for 12 hours. Centrifuge at 4°C, 15000rpm / min for 30min, collect the supernatant, then add ammonium sulfate to the supernatant to make the saturation reach 45%, let stand for 24-48 hours, centrifuge at 4°C, 15000rpm / min for 30min , collect the precipitate and dissolve it with PBS buffer solution with a concentration of 25mM / L a...

Embodiment 2

[0026] (1) Wash the large economical marine red algae asparagus with deionized water;

[0027] (2) Rough extraction of R-phycoerythrin: Superfine asparagus to a particle size of 0.1-0.5mm, crush and add 30 times its volume to PBS buffer solution with a pH of 6.0 and a concentration of 50mM / L, 4 Centrifuge at 9000rpm / min for 20min at 4℃ for 24 hours, then filter the supernatant after centrifugation, and concentrate the filtrate with a 50kd concentrator plate;

[0028](3) Preliminary purification of R-type phycoerythrin: Add solid ammonium sulfate to the crude phycoerythrin extract obtained in step (2) to make the saturation reach 25%, and then let it stand for 12 hours. Centrifuge at 4°C, 12000rpm / min for 20min, collect the supernatant, then add ammonium sulfate to the supernatant to make the saturation reach 45%, let it stand for 6 hours, centrifuge at 4°C, 12000rpm / min for 20min, collect Precipitate and dissolve with PBS buffer solution with a pH of 6.0 and a concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com