A kind of bio-based wear-resistant and antibacterial light-cured floor coating and preparation method thereof

A bio-based, anti-bacterial light technology, applied in epoxy resin coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as discoloration, anti-bacterial agents affecting anti-bacterial effect, and lack of wear resistance of coatings. Achieve the effect of good coating and uniform product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

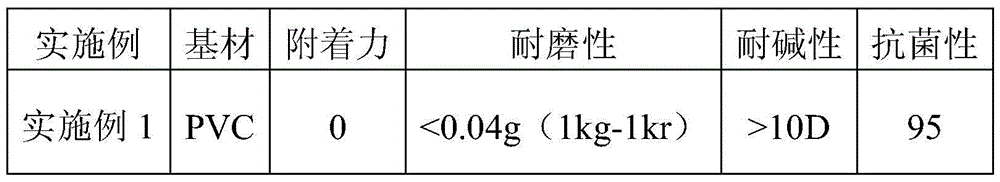

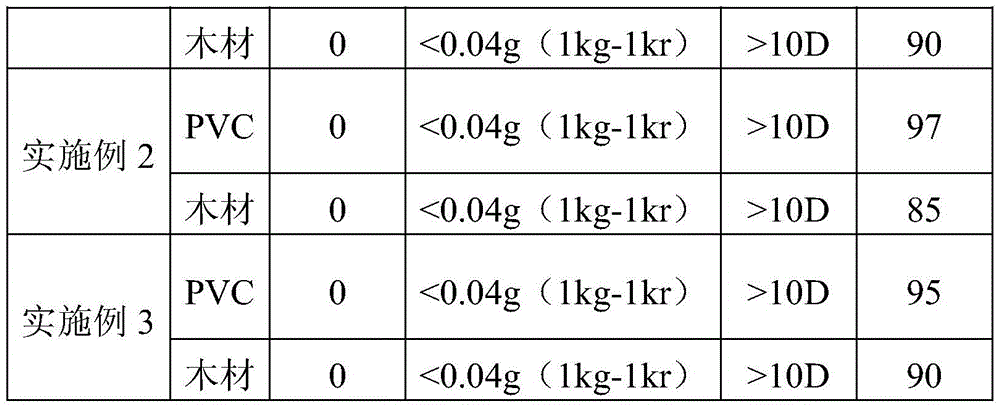

Embodiment 1

[0023] (1) Preparation of monoisocyanate containing unsaturated groups: 22.229g (0.10mol) isophorone diisocyanate, polymerization inhibitor p-4-methoxyphenol 0.07g is added to a magnetic stirrer, thermometer In the three-necked flask, the temperature was raised to 40°C, and the mixture of 12.193g (0.105mol) hydroxyethyl acrylate and catalyst dibutyltin dilaurate 0.004g was dropped drop by drop with a dropping funnel, and the drop rate was controlled, and the drop was completed within 2 hours. Complete the reaction until the isocyanate group content reaches the specified standard, and the reaction is completed to obtain an isocyanate-containing unsaturated monomer;

[0024] (2) Preparation of bio-based light-curable antibacterial resin: 40 g of mixed solvent of 85.06 g (0.05 mol) of tannic acid and butyl acetate / ethanol (mass ratio 5:1) was added to the three ports equipped with a magnetic stirrer and a thermometer. In the flask, the temperature was raised to 70°C, and the isoc...

Embodiment 2

[0028] (1) Preparation of monoisocyanate containing unsaturated groups: 17.415g (0.10mol) toluene diisocyanate and 0.16g of inhibitor p-4-methoxyphenol were added to a three-necked flask equipped with a magnetic stirrer and a thermometer , the temperature was raised to 30°C, and a mixture of 13.643g (0.105mol) hydroxyethyl methacrylate and catalyst dibutyltin dilaurate 0.03g was added drop by drop with a dropping funnel, and the drop rate was controlled, and the drop was completed within 3 hours. React until the content of isocyanate groups reaches the specified standard, and the reaction is completed to obtain an unsaturated monomer containing isocyanate groups;

[0029] (2) Preparation of bio-based photocurable antibacterial resin: 42.53g (0.025mol) of tannic acid and 40g of mixed solvent of butyl acetate / ethanol (mass ratio 2:1) were added to the three ports equipped with magnetic stirrer and thermometer In the flask, the temperature was raised to 75°C, and the isocyanate-c...

Embodiment 3

[0033] (1) Preparation of monoisocyanate containing unsaturated groups: 17.416g (0.10mol) 2,4-toluene diisocyanate and 0.09g of inhibitor p-4-methoxyphenol are added to a mixture equipped with a magnetic stirrer and a thermometer. In a three-necked flask, the temperature was raised to 50°C, and the mixture of 12.193g (0.105mol) hydroxyethyl acrylate and catalyst dibutyltin dilaurate 0.014g was dropped drop by drop with a dropping funnel, and the drop rate was controlled to finish dropping within 2.5h. After the dropwise reaction, the content of the isocyanate group reaches the specified standard, and the reaction is completed to obtain an unsaturated monomer containing isocyanate group;

[0034](2) Preparation of bio-based photocurable antibacterial resin: 40g of mixed solvent of tannic acid 28.35g (0.0167mol) and butyl acetate / ethanol (mass ratio 1:1) was added to a magnetic stirrer equipped with In a three-necked flask with a magnetic stirrer and a thermometer, heat up to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com