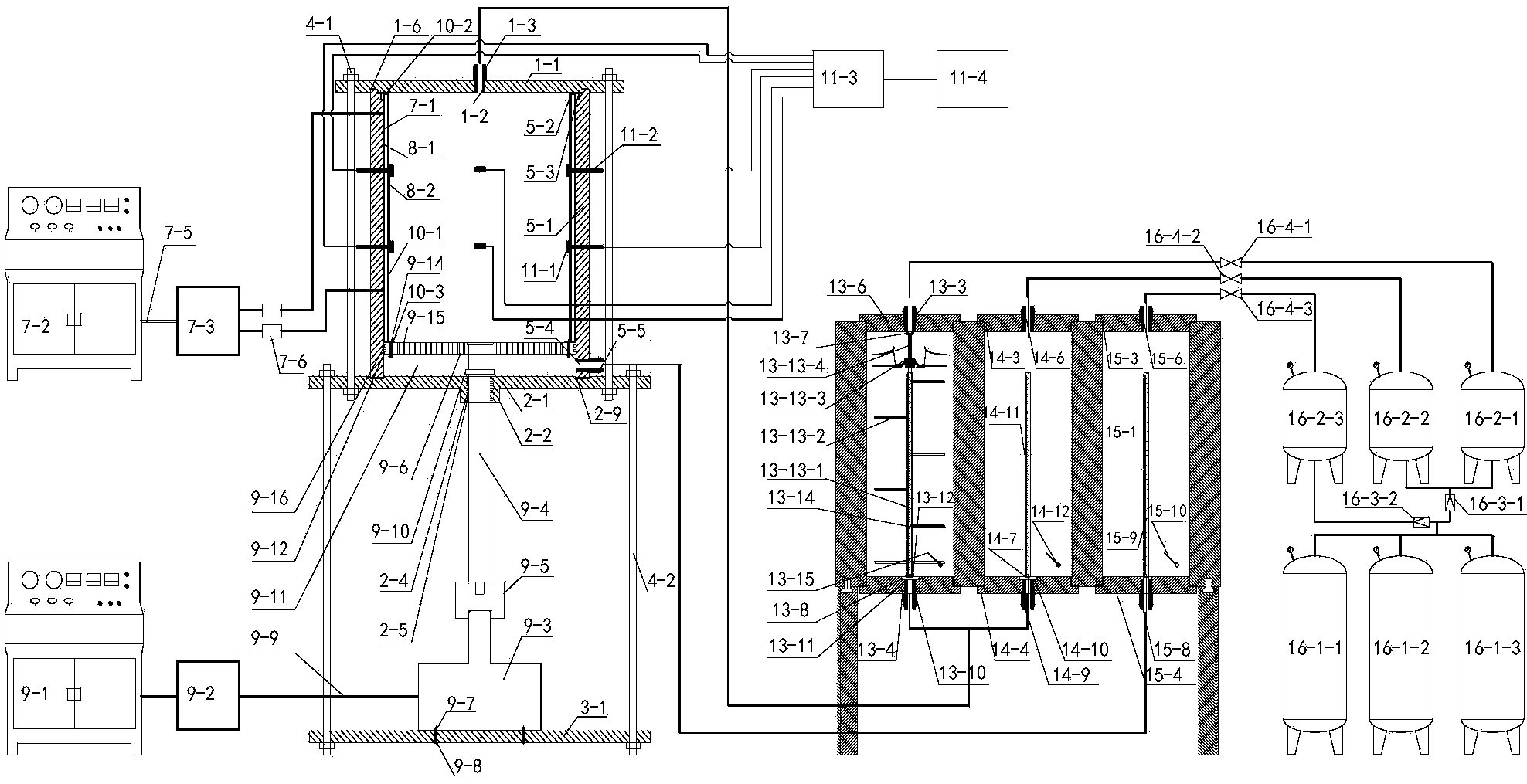

Indoor three-dimensional grouting model test servo control system and test method

A technology of servo control system and grouting model, applied in the direction of control/adjustment system, comprehensive factory control, comprehensive factory control, etc., can solve the mismatch of grouting system, the inability to monitor and adjust grouting parameters in real time, and affect the grouting theory And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

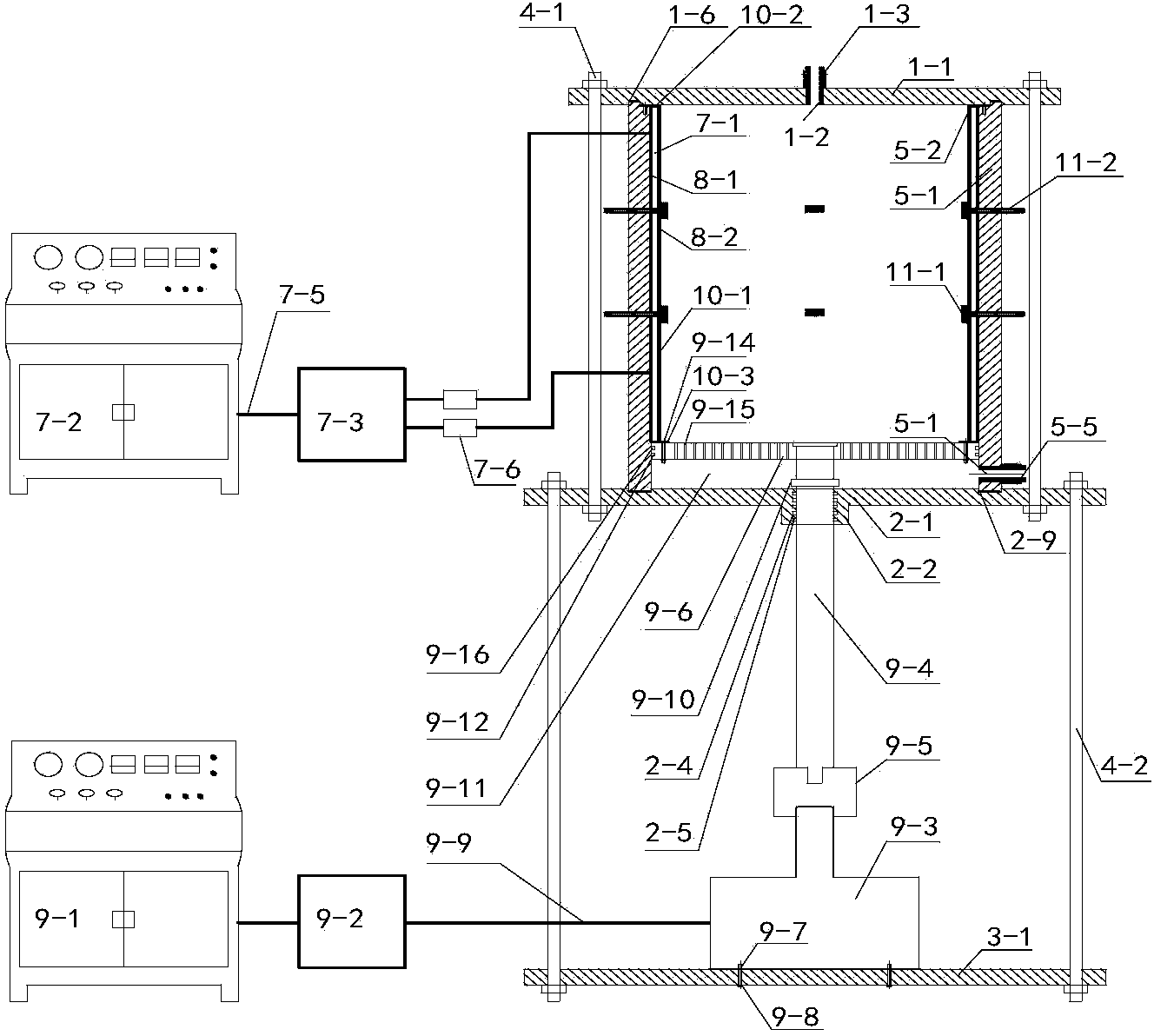

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

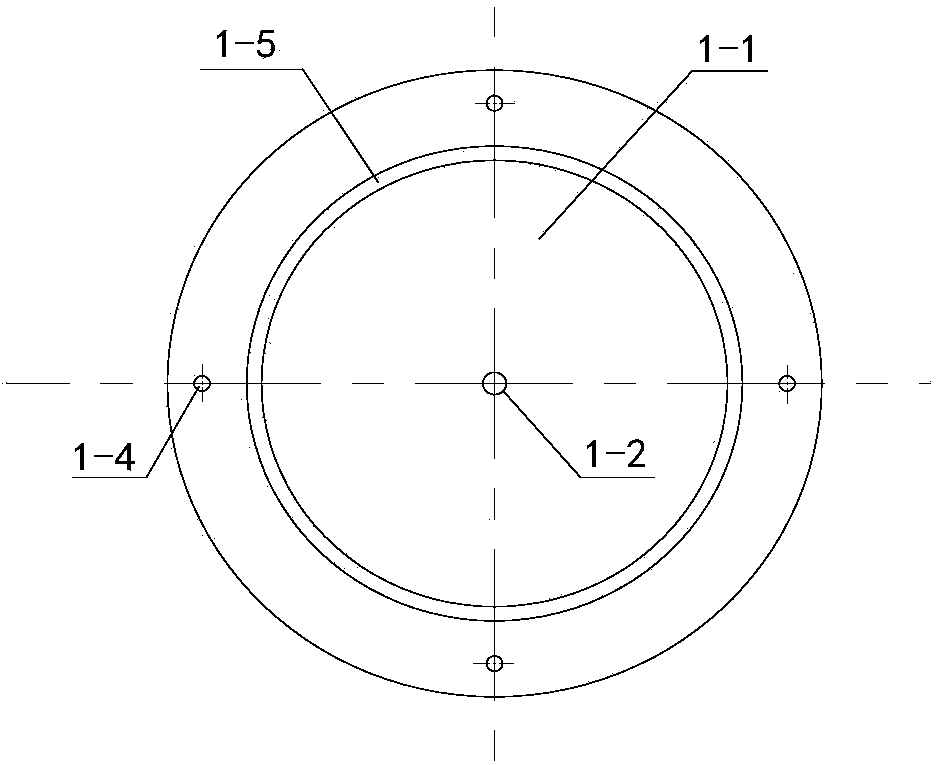

[0071] Such as figure 1 , figure 2 , image 3 As shown, the first reaction force plate 1-1 is processed from high-strength alloy steel material into a disc of Φ660*25mm, that is, a disc with a diameter of 660mm and a height of 25mm. A Φ20mm grouting hole 1-2 is drilled at the center of the first reaction plate, and a mining quick connector I 1-3 is fixed in the hole to connect the slurry storage chambers 13-1 and 14-1; the first reaction plate is drilled on the Φ590mm circumference Set up 4 symmetrically distributed Φ20mm fixing holes I 1-4, so that the fastening screw I 4-1 can pass through; the lower surface of the first reaction plate is processed with a Φ500*470*5mm annular groove I 1-5, with a built-in rubber gasket I 1-6.

[0072] Such as figure 1 , figure 2 , Figure 4 As shown, the second reaction force plate 2-1 is processed into a Φ78...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com