Nanometer high-tech sea sand and river sand harmful substance removal production method and production equipment thereof

A technology for harmful substances and production equipment, applied in the field of cement building materials, can solve the problems of difficult to estimate proportion, waste of water resources, high cost, and achieve the effect of increasing conductive function, improving the quality of finished products, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

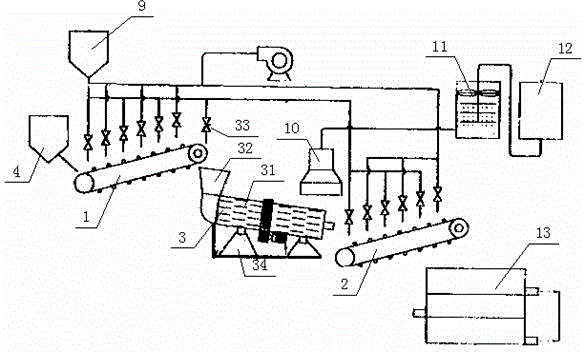

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

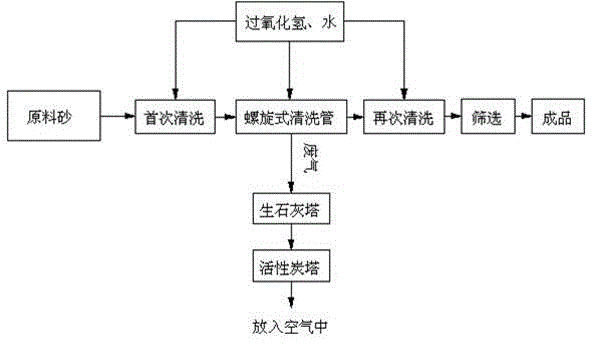

[0028] A nano high-tech production method for removing harmful substances from sea sand and river sand, which is mainly divided into the following steps in sequence:

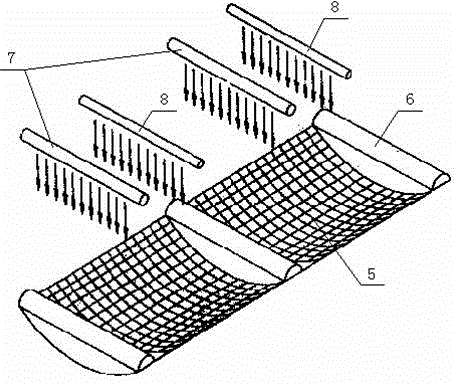

[0029] 1. Use the sewage filter washing method to carry out the first rough washing of sea sand or river sand; the first rough washing can be washed directly with clean water, or washed with a mixed solution of hydrogen peroxide and water, and the raw sand is sent to the sewage filter On the endless belt filter conveyor belt of the machine, start the water spray and blower switch, and carry out the first rough cleaning of the pollution source and tiny dust of the raw sand, so that the content of harmful ions is less than 1%; the interaction between hydrogen peroxide and water can Purify the water quality, and make the hydrogen peroxide remain in the water for use (the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com