(NH4)2V4O9 film and preparation method thereof

A 2V4O9 thin film technology, which is applied in the field of vanadate nanomaterial 2V4O9 thin film and its preparation, can solve the problems of not being able to directly form a film, and achieve the effect of low cost, excellent performance and unique shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Add 0.7mmol of tartaric acid and 60mL of deionized water into the reaction vessel, place it in an ultrasonic cleaner for 30min, then add 5.6mmol of vanadium pentoxide to the reaction vessel and stir for 20min, then add 3mL of directing agent 25% ammonia water dropwise And stir the reaction for 50min to obtain the precursor solution. Take 50mL of the precursor solution and transfer it to a reaction kettle with a polytetrafluoroethylene liner with a volume of 100mL. At the same time, put a piece of quartz substrate rinsed with deionized water into the reaction kettle In the tank, seal the reaction kettle and let it stand for 5 hours, then put the reaction kettle into an oven and heat it to 180°C for 24 hours, and then cool it naturally. After opening the kettle, the substrate was taken out and rinsed once with deionized water, followed by ethanol once, and repeated three times, and dried at 60°C for 8 hours to obtain (NH 4 ) 2 V 4 o 9 film.

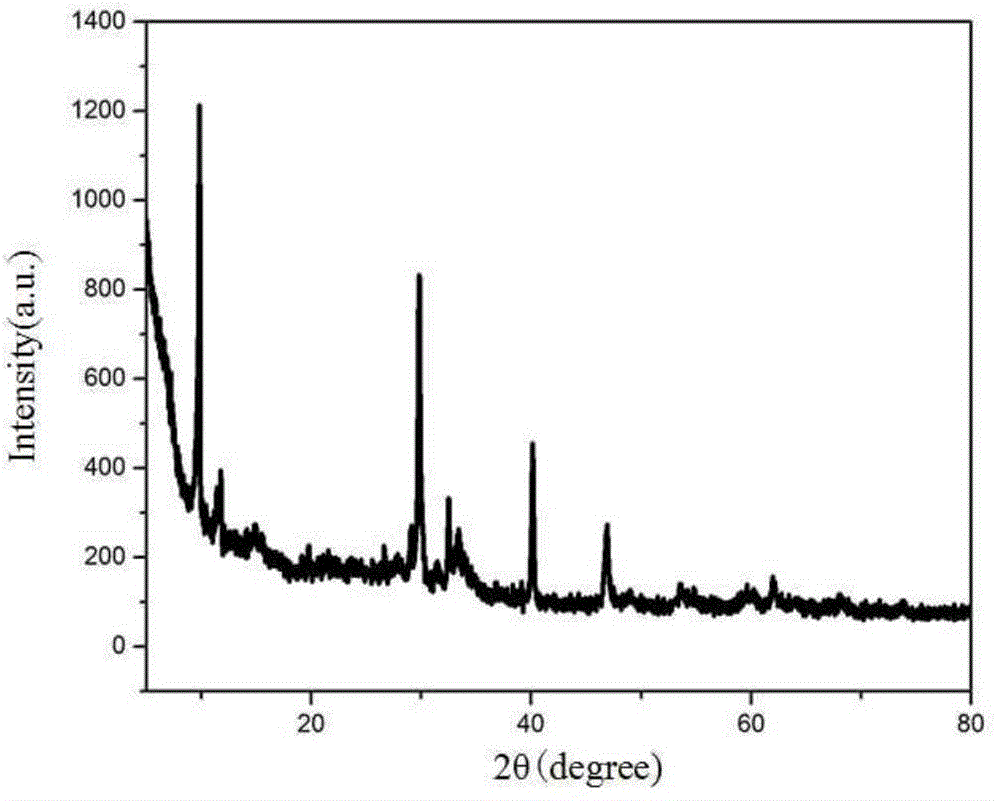

[0064] Such as figure 1 ...

Embodiment 2

[0067] Add 0.7mmol of tartaric acid and 70mL of deionized water into the reaction vessel, place it in an ultrasonic cleaner for 30min, then add 5.9mmol of vanadium pentoxide to the reaction vessel and stir for 30min, then add 6mL of directing agent ammonia water dropwise and stir React for 30 minutes to obtain the precursor solution. Take 60 mL of the precursor solution and transfer it to a 100 mL polytetrafluoroethylene liner reactor. At the same time, put a piece of quartz substrate rinsed with deionized water into the reactor liner. After the reactor was sealed, let it stand for 10 hours, then put the reactor into an oven and heat it to 180°C for 24 hours, then cool it down naturally. After opening the kettle, the substrate was taken out and rinsed once with deionized water, followed by ethanol once, and repeated three times in this way, and dried at 60°C for 10 h to obtain the deposited on the quartz substrate (NH 4 ) 2 V 4 o 9 film.

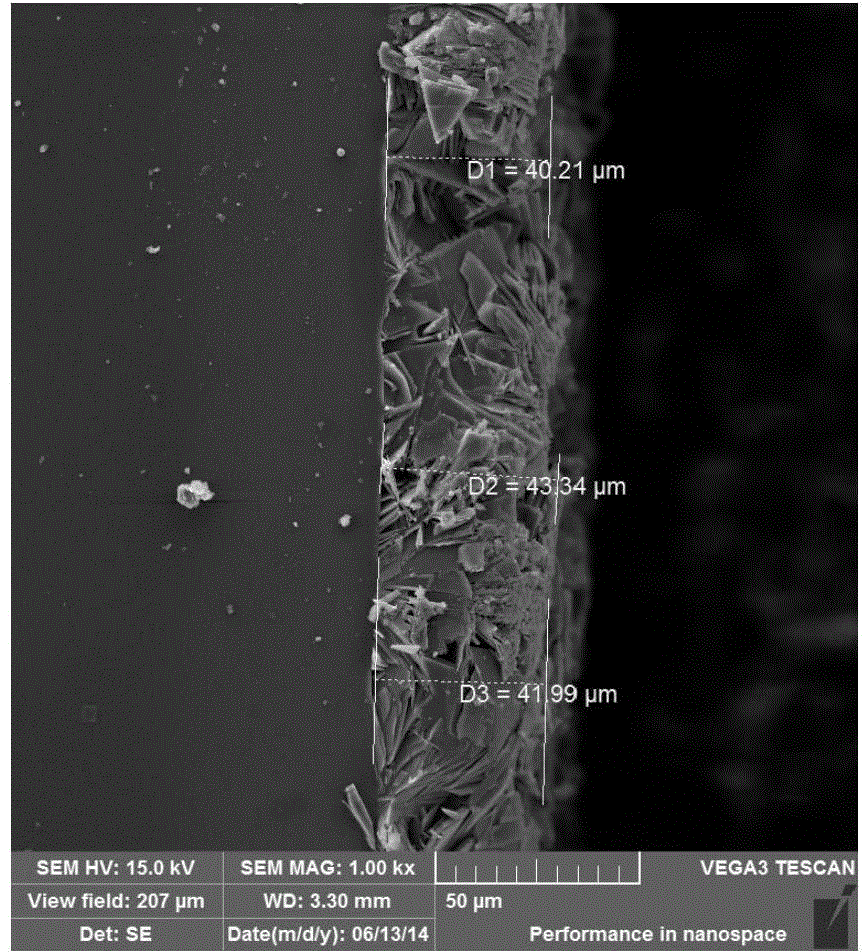

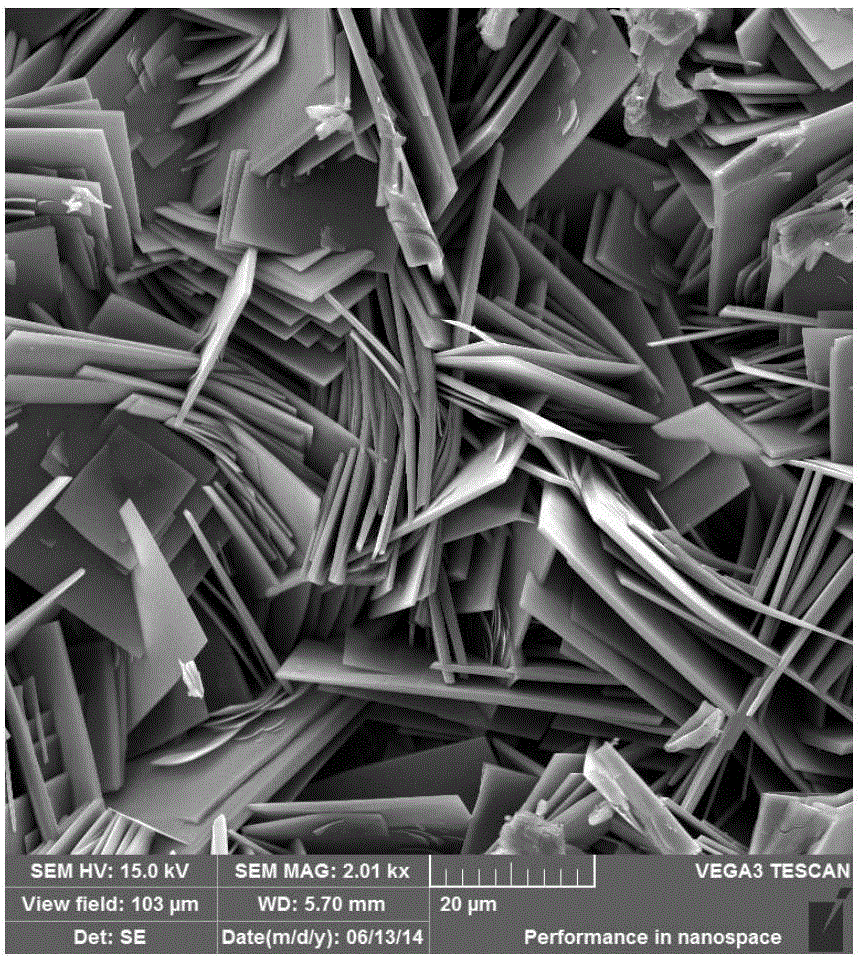

[0068] Such as Figure 4 and F...

Embodiment 3

[0070] Add 0.73mmol of tartaric acid and 40mL of deionized water into the reaction vessel, place it in an ultrasonic cleaner for 20min, then add 6.2mmol of vanadium pentoxide to the reaction vessel and stir for 25min, then add 7mL of directing agent ammonia water dropwise and stir React for 40 minutes to obtain the precursor solution. Take 90 mL of the precursor solution and transfer it to a 100 mL polytetrafluoroethylene liner reactor. At the same time, put a quartz substrate rinsed with deionized water into the reactor liner. After the reactor was sealed, let it stand for 10 hours, then put the reactor into an oven and heat it to 200°C for 24 hours, then cool it down naturally. After opening the kettle, take out the substrate and rinse it once with deionized water, then rinse it once with ethanol, repeat this process three times, and dry it at 60°C for 10 hours to obtain (NH 4 ) 2 V 4 o 9 film.

[0071] Such as Figure 6 and Figure 7 Described, the (NH that the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com