Three-dimensional electrode electro-catalytic reactor wastewater treatment method employing intermittent power supply

A three-dimensional electrode, wastewater treatment technology, applied in electrochemical water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the lack of effective competitiveness of three-dimensional electrode reactors and high energy consumption of three-dimensional electrode reactors , catalysts are easily lost and other problems, to achieve the effect of reducing energy consumption, efficient treatment, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

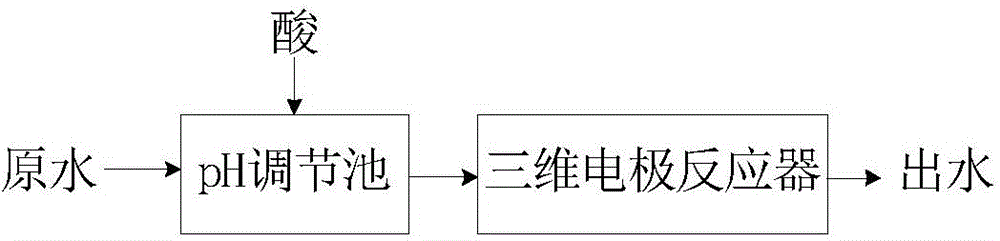

[0026] This embodiment uses a three-dimensional electrode catalytic reactor for reaction treatment of citric acid wastewater, specifically including: the raw wastewater enters COD 155 mg / L, passes through a pH adjustment pool, adds hydrochloric acid to adjust the pH to 5, and then enters a three-dimensional electrode catalytic reactor for reaction. The reaction time HRT is 0.5h and the water will come out.

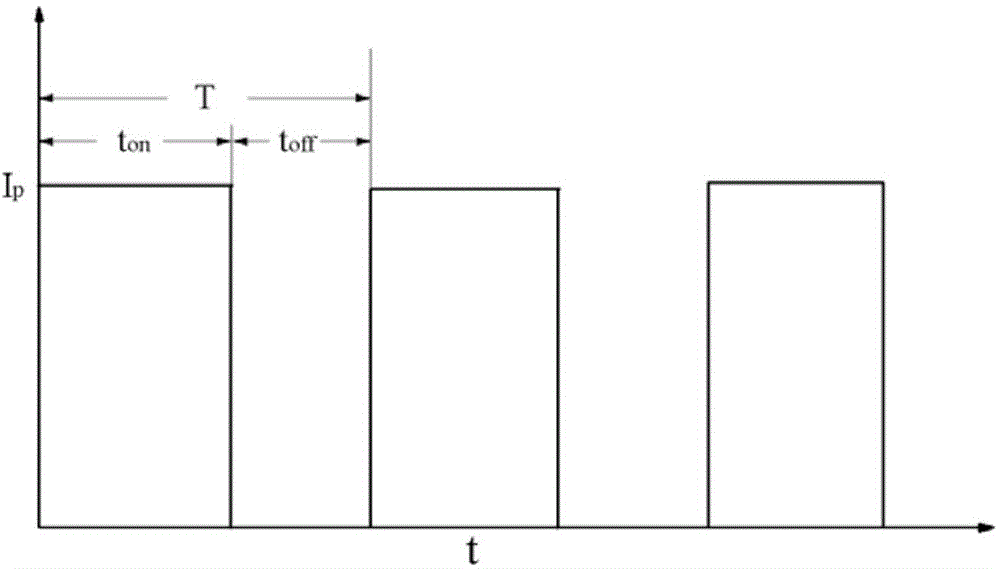

[0027] In this embodiment, the pulse square wave current is used for power supply, and the operating parameters are: pulse square wave current power supply, the pulse duty ratio is 0.2, the pulse frequency is 0.02Hz, and the current density is 2.0mA / cm 2 .

[0028] In this embodiment, the COD removal rate of wastewater can reach 57%, while the energy consumption drops from about 146kWh / kg COD to about 65kWh / kg COD, thus saving energy consumption by kgCOD by 80kWh.

Embodiment 2

[0030] This embodiment uses a three-dimensional electrode catalytic reactor for reaction treatment of citric acid wastewater, specifically including: the COD concentration of the raw wastewater influent is between 160-180mg / L, after passing through the pH adjustment pool, adding hydrochloric acid to adjust the pH to 5, and then entering the three-dimensional The reaction is carried out in the electrode catalytic reactor, and the residence time is 1h. After the treatment, the water from the secondary sedimentation tank is discharged.

[0031] In this embodiment, a pulsed square wave current is used for power supply, and the operating parameters of the three-dimensional electrode catalytic reactor are: the current density is 5mA / cm 2 ,, The pulse duty ratio is 0.4, and the pulse frequency is 0.04Hz.

[0032] In this embodiment, the average COD removal rate of wastewater in continuous operation can reach 60-80%, while the average energy consumption decreases from 118kWh / kgCOD to ...

Embodiment 3

[0034] This embodiment uses a three-dimensional electrode catalytic reactor for reaction treatment of printing and dyeing wastewater, specifically including: the COD concentration of the influent wastewater is between 500-1000 mg / L, the pH value of the adjustment pool is controlled to about 5.5, and the water is discharged into the three-dimensional electrode catalytic reactor. Reaction, the residence time is 2.0h water. ,exist:

[0035] In this embodiment, the pulsed square wave current is used for power supply, and the operating parameters: the current density is 10mA / cm 2 , the pulse duty cycle is 0.35, and the pulse frequency is 0.04Hz.

[0036] In this embodiment, the average COD removal rate of continuous operation wastewater can be higher than 60%, and the energy consumption is 15-30kWh / kgCOD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com