Strong oxidation coagulation and adsorption recovery process for thallium-containing wastewater

A technology of adsorption recovery and strong oxidation, which is applied to the improvement of process efficiency, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of high cost of chemical water treatment, difficult treatment, permanent pollution of water sources, etc., and achieve easy recycling Effects of reuse, large adsorption capacity, and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

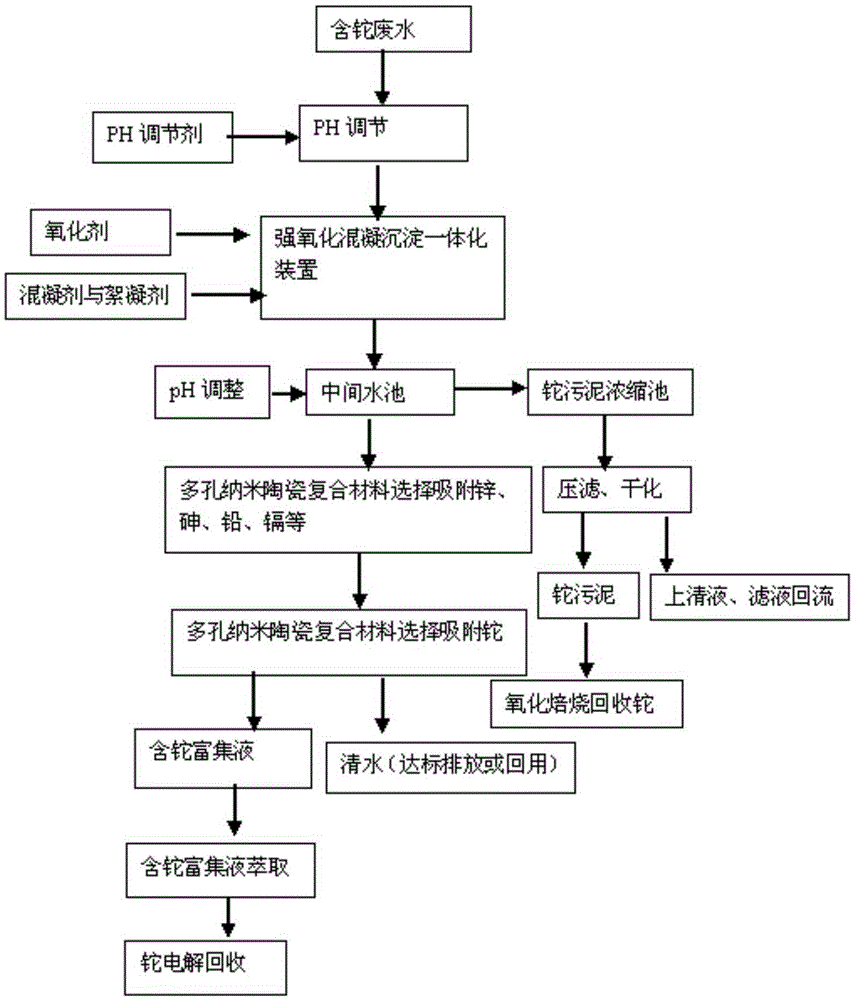

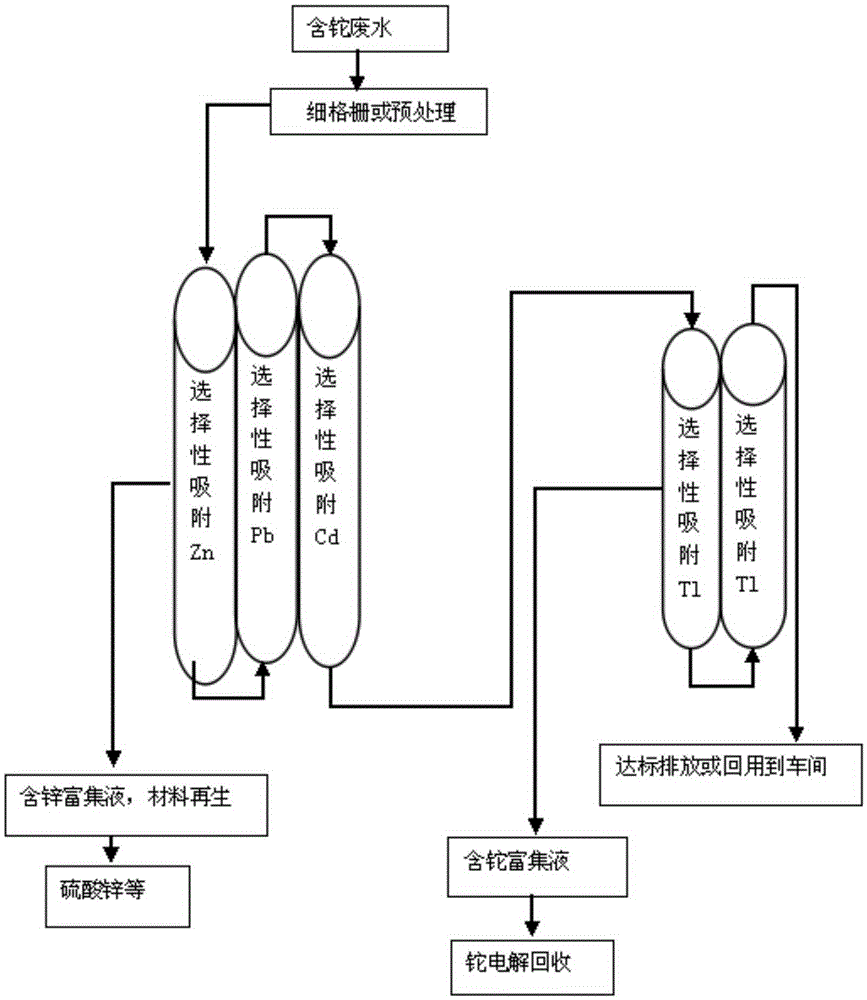

[0057] The strong oxidative coagulation process of thallium-containing wastewater strong oxidative coagulation and adsorption recovery process includes the following steps:

[0058] (1) Concentrate thallium-containing wastewater: Concentrate complex thallium-containing acidic wastewater and production seepage water into the wastewater pool. The wastewater mainly comes from the production process of heavy non-ferrous metal ore (including associated ore), smelting, and non-ferrous chemical industry. Produced; thallium-containing wastewater that poses serious hazards to the surrounding environment and water bodies, and even endangers the lives of local residents.

[0059] (2) pH adjustment: complex thallium-containing acidic wastewater and collected production seepage water enter the pH adjustment tank, and the pH is controlled within 9.2 to 9.5, because the optimum condition for Tl oxidation is pH greater than 8.5, and the optimal pH of the oxidation reaction is controlled at 9.2...

specific Embodiment 2

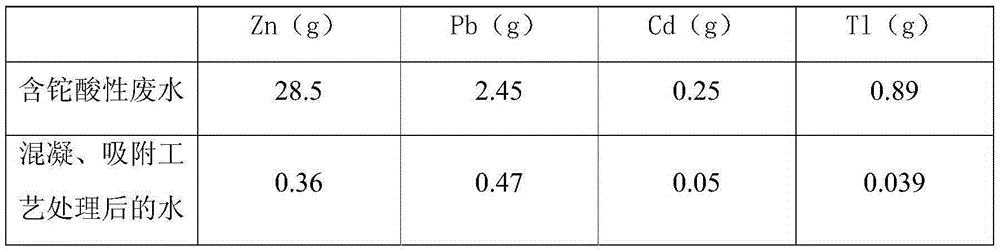

[0090] A total of 100kg of thallium-containing acidic wastewater was treated by the coagulation and adsorption recovery process of thallium-containing wastewater. The comparison table of each heavy metal content in thallium-containing acidic wastewater and the content of various metals in water after coagulation and adsorption treatment is as follows:

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com