Preparation method for double quaternary ammonium side long chain anion-exchange membrane

A technology of anion exchange membrane and diquaternary ammonium, which is applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problem of limiting anion exchange membrane anion conductivity, poor microscopic hydrophilic and hydrophobic phase separation ability, and unsuitable for large-scale In order to achieve the effect of improving ion conductivity, cheap raw materials, and promoting the separation of microscopic hydrophilic and hydrophobic phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

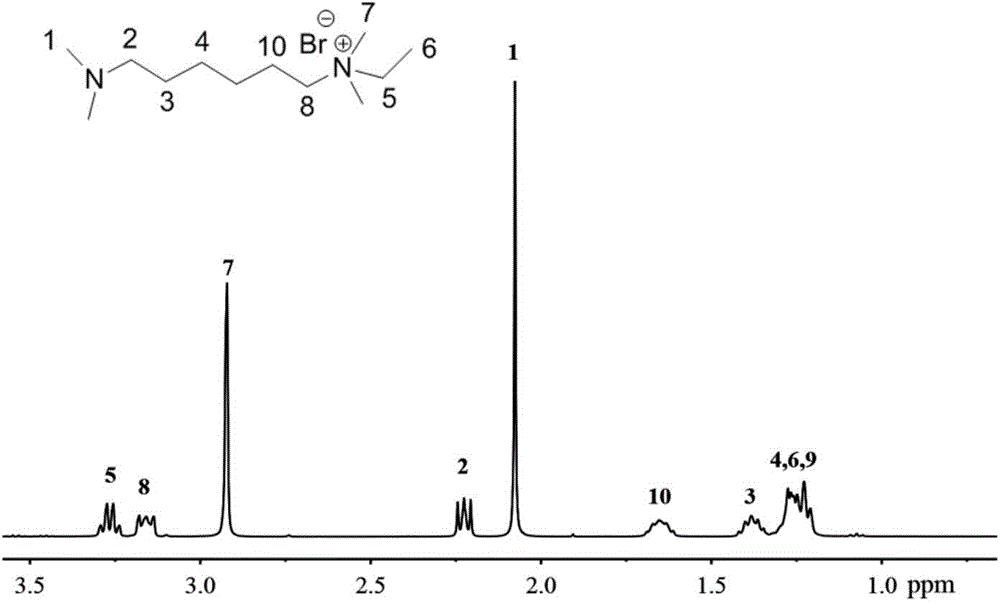

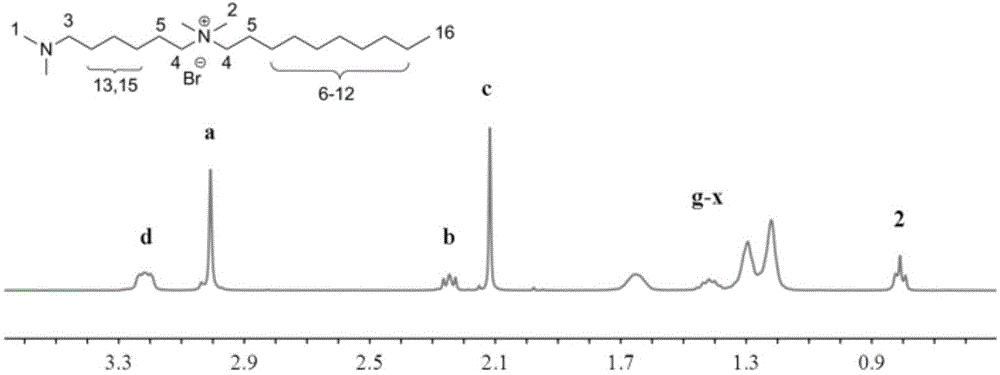

[0043] Preparation of 6-(dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide: 1 mL of N,N,N',N'-tetramethyl-1,6-hexyl The diamine was dissolved in 19 mL of ethanol to form a 5% solution by volume, and 1-fold molar amount of 1-bromoethane was added to react at room temperature for 48 h. Rotary evaporation to remove ethanol, add an appropriate amount of acetone, filter to remove the precipitate, the filtrate is processed by rotary evaporation, remove the acetone, wash with ether several times, and filter to obtain 6-(dimethylamino)hexyl-N,N-dimethyl- N-Ethylammonium bromide.

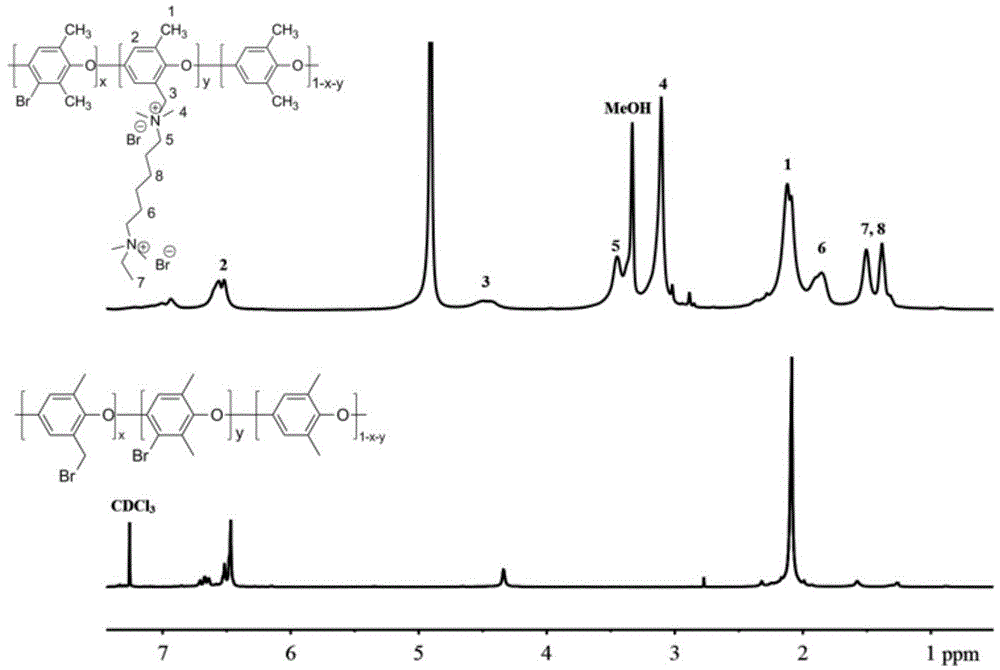

[0044] Preparation of double quaternary ammonium side long-chain anion exchange membrane: 0.3g of brominated polyphenylene ether with a bromination degree of 0.084 was dissolved in 3mL (2.92g) of N-methyl-2-pyrrolidone, and then 0.084g of 6- (Dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide, stirred at room temperature for 12 hours to obtain a uniform casting solution. The above-mentioned ca...

Embodiment 2

[0049] The preparation of 6-(dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide: same as Example 1

[0050] Preparation of double quaternary ammonium side long-chain anion exchange membrane: 0.3g of brominated polyphenylene ether with a bromination degree of 0.093 was dissolved in 3mL (2.92g) of N-methyl-2-pyrrolidone, and then 0.092g of 6- (Dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide, stirred at room temperature for 12 hours to obtain a uniform casting solution, and evenly coated the above casting solution on a glass plate, at 60°C After drying for 12 hours, soaking in deionized water for 12 hours, the double-quaternary ammonium-side long-chain anion exchange membrane is obtained.

[0051] Water content and ion exchange capacity tests show that the water content of the anion exchange membrane prepared in this example is 18.2%, and the anion exchange capacity is 1.24mmol.g -1 ; OH of the film - The conductance is 21.6mS.cm -1 , the tensile strength is 33....

Embodiment 3

[0053] The preparation of 6-(dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide: same as Example 1

[0054] Preparation of double quaternary ammonium side long-chain anion exchange membrane: 0.3g of brominated polyphenylene ether with a bromination degree of 0.13 was dissolved in 3mL (2.92g) of N-methyl-2-pyrrolidone, and then 0.126g of 6-( Dimethylamino)hexyl-N,N-dimethyl-N-ethylammonium bromide, stirred at room temperature for 12 hours to obtain a uniform casting solution, uniformly coated the above casting solution on a glass plate, and baked at 60°C Dry for 12 hours, and then soak in deionized water for 12 hours to obtain a double-quaternary ammonium side long-chain anion exchange membrane.

[0055] The water content and ion exchange capacity tests show that the water content of the anion exchange membrane prepared in this example is 42.5%, and the anion exchange capacity is 1.60mmol.g -1 ; OH of the film - The conductance is 36.3mS.cm -1 , the tensile strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com