Polyketone anion exchange membrane and preparation method thereof

An anion-exchange membrane and polyketone-based membrane technology, applied in the field of polyketone resin-based anion-exchange membrane and its preparation, to achieve high ion conductivity, good mechanical properties and thermal stability, low swelling and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

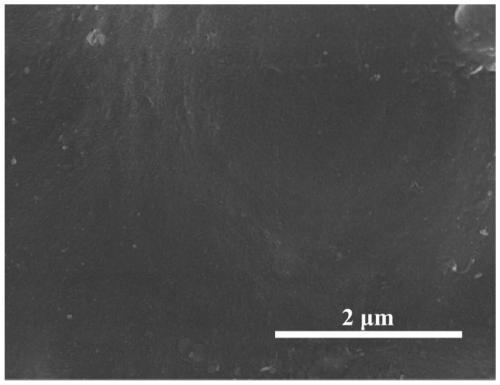

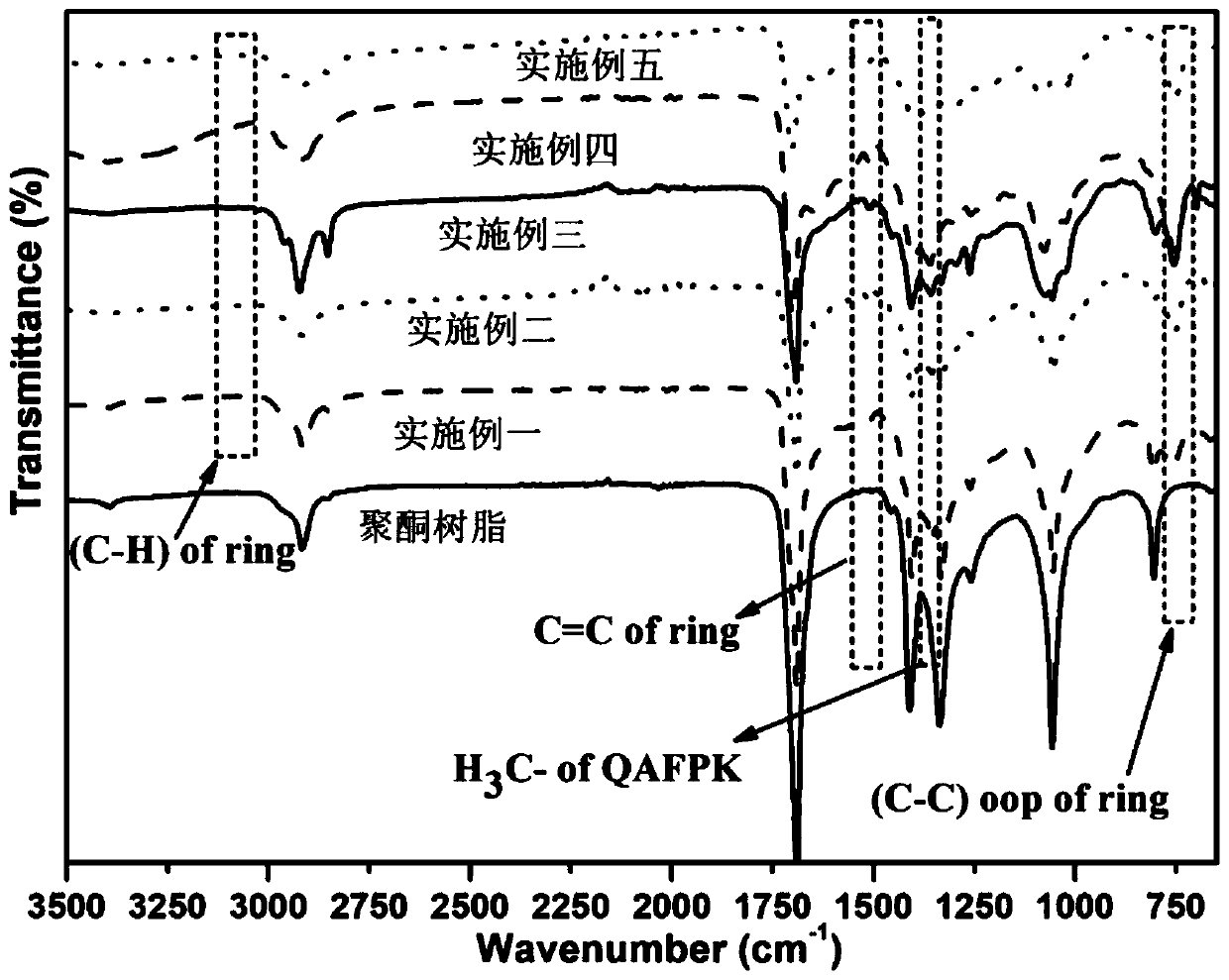

Image

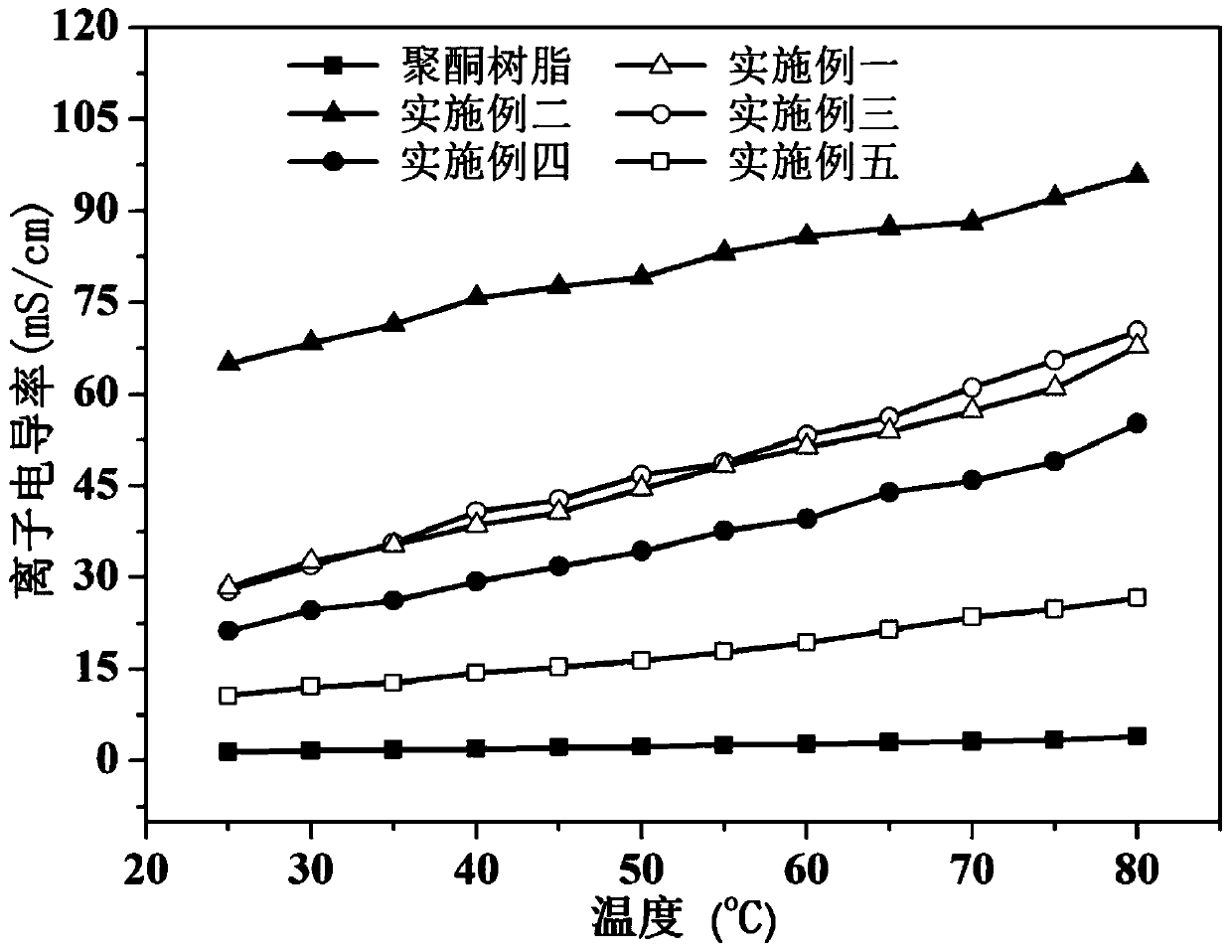

Examples

preparation example Construction

[0038] The invention provides a method for preparing an anion exchange membrane. The polyketone resin is dissolved, reacted with a diamine in a solution state, cast the film using the reacted solution, then reacted with methyl iodide, and then reacted with sodium hydroxide The ion exchange membrane is carried out, and the polyketone resin-based anion exchange membrane is obtained after drying.

[0039] The preparation method of polyketone-based anion exchange membrane of the present invention can adopt following preparation method:

[0040] 1) Add the dried and weighed polyketone resin into a mixed solvent of hexafluoroisopropanol and dichloromethane with a mass ratio of 1:2.33, and stir and dissolve for 20 minutes at room temperature to obtain a polyketone solution;

[0041] 2) Add reactant polyketone 2.5mmol% bismuth nitrate to the obtained polyketone resin solution, and help it disperse by ultrasonic and stirring; add 1,2-propylenediamine after 5min, wherein 1,2-propylenedi...

Embodiment 1

[0051] (1) Add 0.5 g of the dried and weighed polyketone resin into a mixed solvent of hexafluoroisopropanol and dichloromethane with a mass ratio of 1:2.33, and stir at room temperature for 20 minutes to prepare polyketone with a mass fraction of 2.5 wt%. resin solution;

[0052] (2) Add 43.42 mg of bismuth nitrate to the obtained polyketone resin solution, and disperse it by ultrasonic and stirring; add 47 μL of 1,2-propylenediamine (diamine and 1,4-dicarbonyl) after 5 minutes The reaction molar ratio is 1:8), stirred and reacted for 13 hours at 30°C;

[0053] (3) The reaction solution obtained in the previous step was left still for 5 minutes at 10° C. to remove the bismuth nitrate precipitated from the bottom layer. This process was repeated 3 times to obtain the casting solution; Cast into a film in the frame;

[0054] (4) Put the membrane obtained in step (3) into ethanol to fully wash it for 3 to 4 times, and dry it at 60°C; soak the dried membrane in methyl iodide, rea...

Embodiment 2

[0057] (1) Add 0.5 g of the dried and weighed polyketone resin into a mixed solvent of hexafluoroisopropanol and dichloromethane with a mass ratio of 1:2.33, and stir at room temperature for 20 minutes to prepare polyketone with a mass fraction of 2.5 wt%. resin solution;

[0058] (2) Add 43.42 mg of bismuth nitrate to the obtained polyketone resin solution, and disperse it by ultrasonic and stirring; add 62 μL of 1,2-propylenediamine (diamine and 1,4-dicarbonyl) after 5 minutes The reaction molar ratio is 1:6), stirred and reacted for 13 hours at 30°C;

[0059] (3) The reaction solution obtained in the previous step was left still for 5 minutes at 10° C. to remove the bismuth nitrate precipitated from the bottom layer. This process was repeated 3 times to obtain the casting solution; Cast into a film in the frame;

[0060] (4) Put the membrane obtained in step (3) into ethanol to fully wash it for 3 to 4 times, and dry it at 60°C; soak the dried membrane in methyl iodide, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com