A gradient anti-corrosion concrete foundation for transmission line towers

A technology for concrete foundations and power transmission lines, applied in the field of concrete foundations, can solve problems such as affecting the safe operation of concrete structures, failing to achieve anti-corrosion effects, etc., and achieve the effects of improving the anti-sulfate corrosion effect, ensuring safe and stable operation, and having a simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

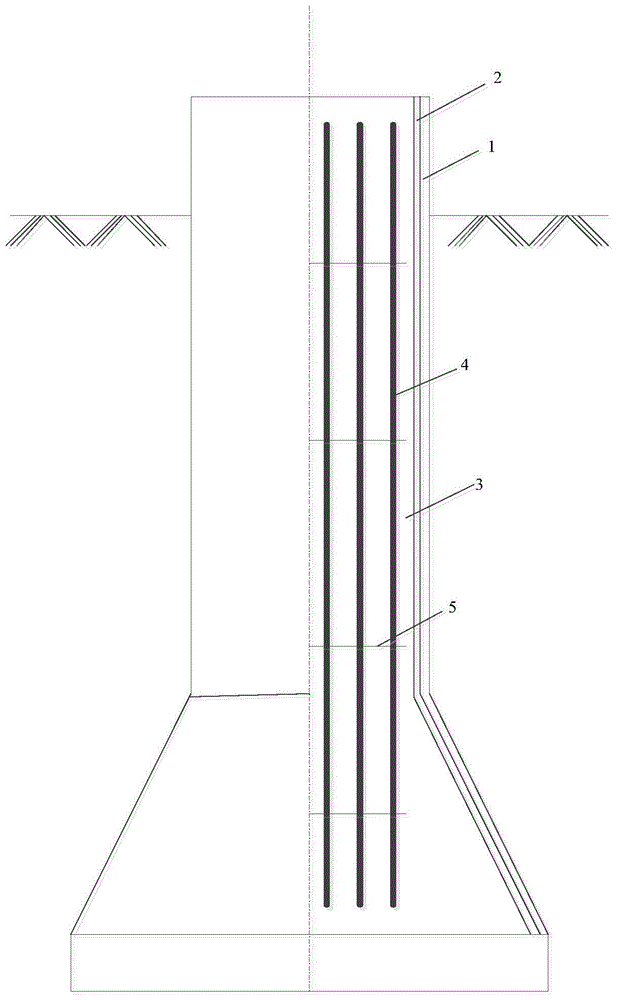

[0018] A gradient anti-corrosion concrete foundation for a power transmission line pole tower, which is composed of a high impermeability waterproof layer (1), an outer anti-corrosion layer (2) and a reinforced concrete structure layer (3), and the high-impermeability waterproof layer (1) is located on the outer anti-corrosion layer (2 ), the outer anticorrosion layer (2) is located on the outer surface of the reinforced concrete structural layer (3).

[0019] The high impermeability and waterproof layer is a high impermeability and waterproof coating material with a thickness of 30mm sprayed by high chloride polyethylene.

[0020] The outer anti-corrosion layer has a thickness of 80mm and is made of the following raw materials in parts by mass: 25 parts of cement, 15.73 parts of mineral admixture, 50 parts of extra fine sand, 8 parts of water, 0.17 part of fiber, and 0.5 part of shrinkage reducing agent , 0.6 parts of naphthalene-based water reducer.

[0021] The concrete st...

Embodiment 2

[0025] A gradient anti-corrosion concrete foundation for a power transmission line pole tower, which is composed of a high impermeability waterproof layer (1), an outer anti-corrosion layer (2) and a reinforced concrete structure layer (3), and the high-impermeability waterproof layer (1) is located on the outer anti-corrosion layer (2 ), the outer anticorrosion layer (2) is located on the outer surface of the reinforced concrete structural layer (3).

[0026] The high impermeability and waterproof layer is a high impermeability and waterproof coating material with a thickness of 25mm sprayed by high chloride polyethylene.

[0027] The thickness of the outer anti-corrosion layer is 60 mm, and it is made of the following raw materials in parts by mass: 23 parts of cement, 16 parts of mineral admixture, 50 parts of ultra-fine sand, 10 parts of water, 0.15 part of fiber, and 0.45 part of shrinkage reducing agent , 0.4 parts of naphthalene-based water reducer.

[0028] The concre...

Embodiment 3

[0031] A gradient anti-corrosion concrete foundation for a power transmission line pole tower, which is composed of a high impermeability waterproof layer (1), an outer anti-corrosion layer (2) and a reinforced concrete structure layer (3), and the high-impermeability waterproof layer (1) is located on the outer anti-corrosion layer (2 ), the outer anticorrosion layer (2) is located on the outer surface of the reinforced concrete structural layer (3).

[0032] The high impermeability and waterproof layer is a high impermeability and waterproof coating material with a thickness of 20mm sprayed by high chloride polyethylene.

[0033] The thickness of the outer anti-corrosion layer is 50mm, and it is made of the following raw materials in parts by mass: 20 parts of cement, 15 parts of mineral admixture, 53.15 parts of ultra-fine sand, 11 parts of water, 0.15 part of fiber, and 0.4 part of shrinkage reducing agent , 0.3 parts of naphthalene-based water reducer.

[0034] The concr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com