A kind of multifunctional concrete synergist and preparation method thereof

A concrete synergist and multifunctional technology, applied in the field of concrete admixtures, can solve problems such as difficulty in obtaining raw materials, poor environmental performance of the final product in the preparation process, and environmental pollution, and achieve social and economic benefits of energy saving and consumption reduction. Superposition effect, the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

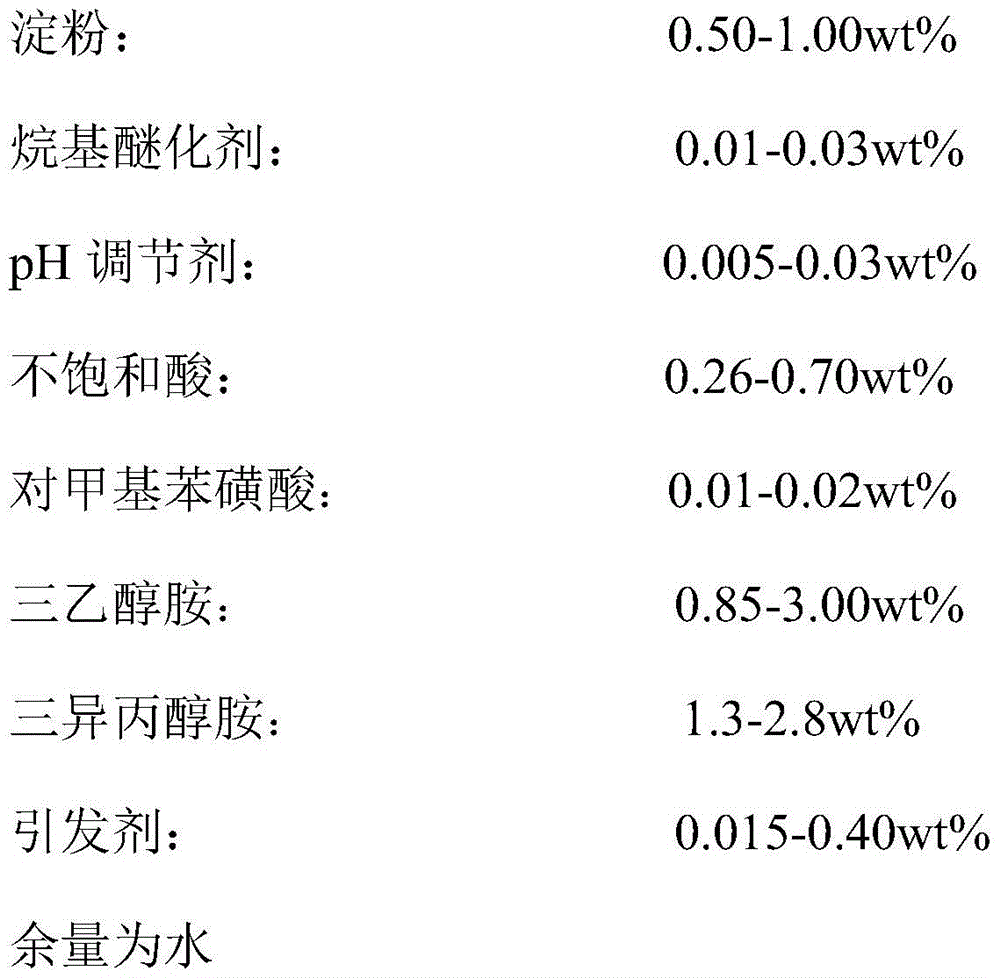

[0032] The content of each component required for the reaction is as shown in Table 1, wherein the starch is a mixture of corn starch and wheat starch, the mass ratio is 1:1, the alkyl etherification agent is ethylene oxide, and the pH regulator is hydrogenated The mixture of sodium and potassium hydroxide, the mass ratio is 4:1, the unsaturated acid is maleic acid used in the preparation of esterification product 1 and preparation product 2, and its percentages are respectively 0.48wt% and 0.22wt% , The initiator is a mixture of sodium persulfate and ammonium persulfate, the mass ratio is 2:1.

[0033] Concrete preparation process steps and parameters are as follows:

[0034] (1) Add starch and water to the reactor first, stir until it is completely dissolved, configure sodium hydroxide and potassium hydroxide into a solution with a content of 5.00%, add it to the above reaction system and adjust the pH value of the system to 12 , and then add ethylene oxide to the reaction ...

Embodiment 2

[0038] The content of each component required for the reaction is as shown in Table 1, wherein the starch is tapioca starch, the alkyl etherification agent is ethylene oxide, the pH regulator sodium hydroxide, and the unsaturated acid is prepared in the esterification product 1 and When preparing the product 2, acrylic acid and maleic acid were used respectively, and their percentages were 0.14 wt% and 0.29 wt%, respectively, and the initiator was potassium persulfate.

[0039] Concrete preparation process steps and parameters are as follows:

[0040] (1) Add tapioca starch and water to the reactor first, stir until it is completely dissolved, configure sodium hydroxide into a solution with a content of 10.00%, add it to the above reaction system and adjust the pH value of the system to 11, and then proceed to the reaction Ethylene oxide was added into the system, and the etherification reaction was carried out at 40°C for 14.0h.

[0041] (2) Preparation of esterification pro...

Embodiment 3

[0044] The content of each component required for the reaction is as shown in Table 1, wherein the starch is cornstarch, the alkyl etherification agent is a mixture of propylene oxide and ethylene oxide, the mass ratio is 1:1, and the pH regulator hydrogen Sodium oxide, unsaturated acid is to use the mixture of acrylic acid, maleic anhydride respectively when preparing esterification product 1 and preparation product 2, and mass ratio is the mixture of 36:49 and acrylic acid, maleic acid, and mass ratio is 18: 29. The percentages are 0.286wt% and 0.188wt%, respectively. The initiator is a mixture of sodium persulfate, potassium persulfate and ammonium persulfate, and the mass ratio is 1:1:1.

[0045] (1) Add cornstarch and water in the reactor, stir until it dissolves completely, configure sodium hydroxide and water into a solution with a content of 10.00%, add it to the above reaction system and adjust the pH value of the system to 11.5, and then Propylene oxide and ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com