Method for arranging multiple layers of electronic elements on single-surface stereo circuit and device prepared by the same

A technology of three-dimensional circuits and electronic components, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of inability to place parts and small internal space, and achieve the effect of saving internal space, saving resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

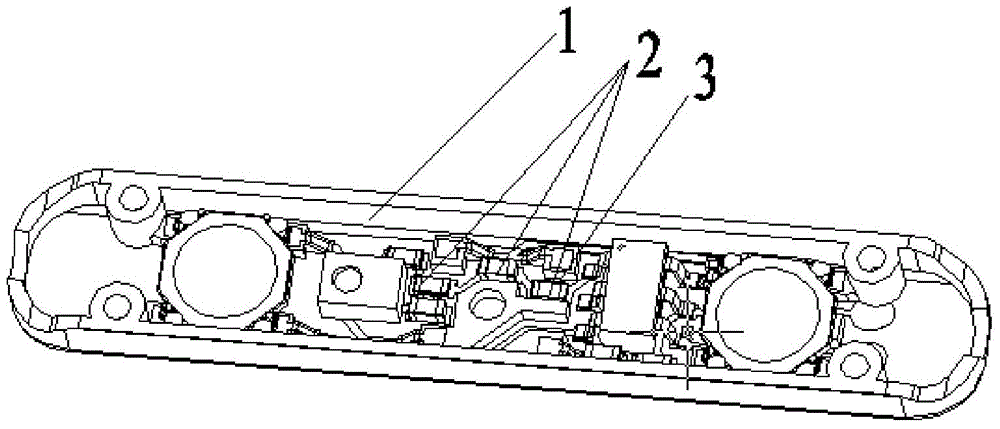

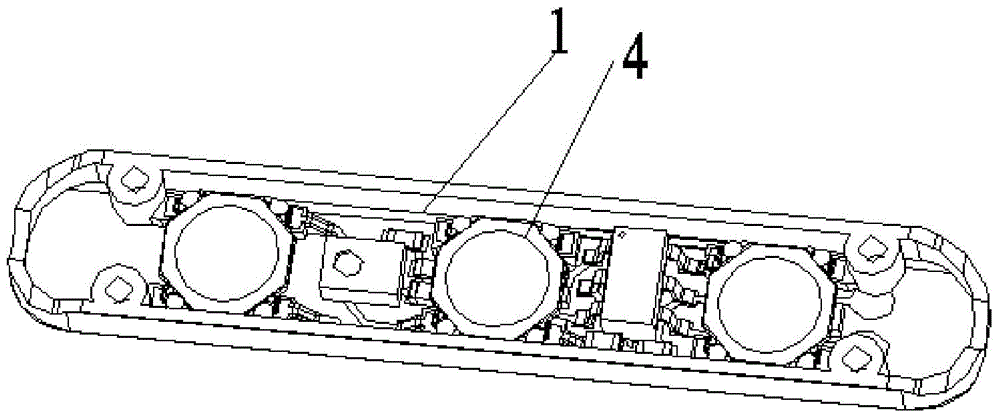

[0030] A method for placing multilayer electronic components on a single-sided three-dimensional circuit, comprising the following steps:

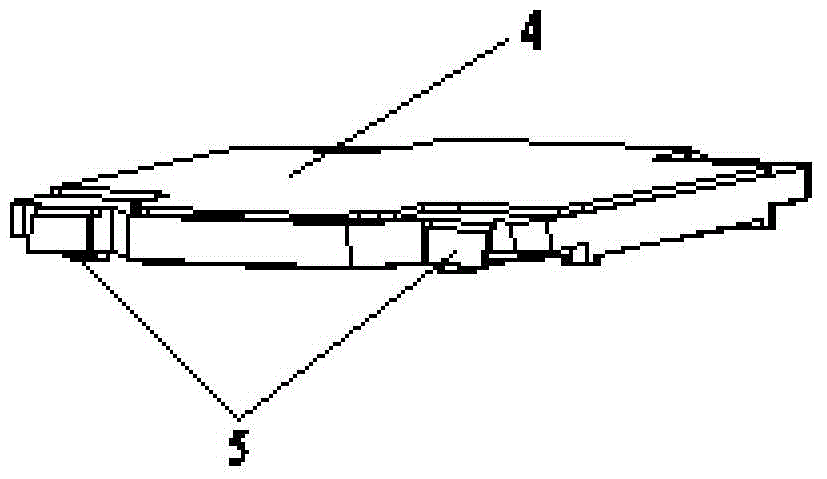

[0031] 1) Firstly, a pit for assembling small packaged electronic components is formed on the plastic structural part;

[0032] 2) Then, absorb a layer of copper powder on the plastic structure with pits obtained in step 1;

[0033] 3) Place the plastic structural parts that have absorbed the copper powder in step 2 in a nitrogen atmosphere, and then a laser machine loaded with a designed circuit pattern selectively scans the copper powder, and the scanned copper powder instantly melts and combines with the plastic The structural parts are welded together to form a three-dimensional circuit, and then the machine vibrates to shake off the unscanned copper powder;

[0034] 4) Finally, assemble small packaged electronic components on the three-dimensional circuit in the pit of the plastic structural part, and assemble large packaged electron...

Embodiment 2

[0041] A method for placing multilayer electronic components on a single-sided three-dimensional circuit, comprising the following steps:

[0042] 1) Firstly, a pit for assembling small packaged electronic components is formed on the plastic structural part;

[0043] 2) Then spray one layer of aluminum powder on the plastic structural part with pits obtained in step 1;

[0044] 3) Place the plastic structural parts sprayed with aluminum powder in step 2 in an argon atmosphere, and then a laser machine loaded with a designed circuit pattern selectively scans the aluminum powder, and the scanned aluminum powder instantly melts and combines with the plastic The structural parts are welded together to form a three-dimensional circuit, and then the unscanned aluminum powder is removed with a brush;

[0045] 4) Finally, assemble small packaged electronic components on the three-dimensional circuit in the pit of the plastic structural part, and assemble large packaged electronic com...

Embodiment 3

[0051] A method for placing multilayer electronic components on a single-sided three-dimensional circuit, comprising the following steps:

[0052] 1) Firstly, a pit for assembling small packaged electronic components is formed on the plastic structural part;

[0053] 2) then spread a layer of nickel powder on the plastic structural part with pits obtained in step 1;

[0054] 3) Place the plastic structural parts covered with nickel powder in step 2 in a carbon dioxide atmosphere, and then selectively scan the nickel powder with a laser machine loaded with a designed circuit pattern. The scanned nickel powder melts instantly, and the plastic structure The pieces are welded together to form a three-dimensional circuit, and then the unscanned nickel powder is removed with a brush;

[0055] 4) Finally, assemble small packaged electronic components on the three-dimensional circuit in the pit of the plastic structural part, and assemble large packaged electronic components on the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com