Preparation method of industrial antitoxin efficient impregnated carbon

An impregnated carbon, high-efficiency technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as inability to meet protection requirements, achieve timely and effective purification efficiency, good versatility, and universality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

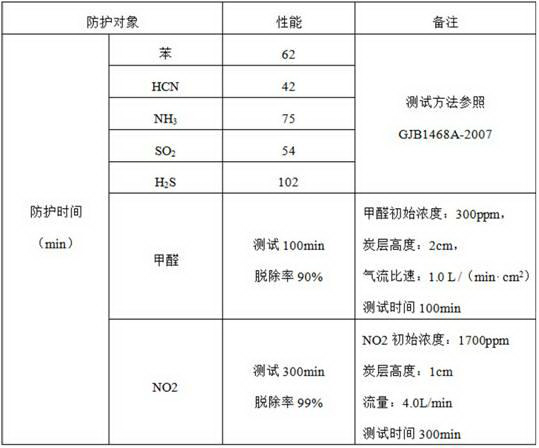

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An industrial anti-toxic high-efficiency impregnated carbon, using coconut shell crushed activated carbon as the carrier skeleton material, loaded with 15% (weight) of Cu, 2% (weight) of Mo, 3% (weight) of Zn, 4% (weight) ) CO 3 2- , 10 wt% SO 4 2- .

[0024] Wherein, the weight of the carrier material activated carbon is 100%, such as activated carbon 100g, copper 15g, molybdenum 2g, zinc 3g, carbonate ion 4g, sulfate ion 10g; then active component basic copper carbonate 25.5g, molybdic acid Ammonium 4g, basic zinc carbonate 5.4g, ammonium carbonate 6.4g, ammonium sulfate 14g.

[0025] The preparation method of above-mentioned efficient impregnated carbon is as follows:

[0026] (1) Mixed solution configuration: Add the impregnating agent containing the above active components into the calculated mixed solvent of ammonia water and distilled water (the ratio of ammonia water to distilled water is 20:1; use the same amount of impregnation method, and those skilled i...

Embodiment 2

[0030] An industrial anti-virus high-efficiency impregnated carbon, using coconut shell crushed activated carbon as the carrier skeleton material, loaded with 18% (weight) of Cu, 4% (weight) of Mo, 1.5% (weight) of Zn, 2% (weight) ) CO 3 2- , 8 wt% SO 4 2- .

[0031] Wherein, the weight of the carrier material activated carbon is 100%, such as activated carbon 100g, copper 18g, molybdenum 4g, zinc 1.5g, carbonate ion 2g, sulfate ion 8g; then the active component basic copper carbonate 30.6g, molybdenum Ammonium acid 8g, basic zinc carbonate 2.7g, ammonium carbonate 3.2g, ammonium sulfate 11.2g.

[0032] The preparation method of above-mentioned efficient impregnated carbon is as follows:

[0033](1) Mixed solution configuration: Add the impregnating agent containing the above active components into the calculated mixed solvent of ammonia water and distilled water (the ratio of ammonia water and distilled water is 20:1; use the same amount of impregnation method, the amoun...

Embodiment 3

[0037] An industrial anti-toxic high-efficiency impregnated carbon, using coconut shell crushed activated carbon as the carrier skeleton material, loaded with 20% (weight) of Cu, 5% (weight) of Mo, 0.5% (weight) of Zn, 5% (weight) ) CO 3 2- , 5 wt% SO 4 2- .

[0038] Wherein, the weight of the carrier material activated carbon is 100%, such as activated carbon 100g, copper 20g, molybdenum 5g, zinc 0.5g, carbonate ion 5g, sulfate ion 5g; then the active component basic copper carbonate 34g, molybdenum acid Ammonium 10g, basic zinc carbonate 0.9g, ammonium carbonate 8g, ammonium sulfate 7g.

[0039] The preparation method of above-mentioned efficient impregnated carbon is as follows:

[0040] (1) Mixed solution configuration: Add the impregnating agent containing the above active components into the calculated mixed solvent of ammonia water and distilled water (the ratio of ammonia water and distilled water is 20:1; use the same amount of impregnation method, the amount use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com