A method of extracting sinigrin

A technology of sinigrin and extract, which is applied in the field of preparation of active ingredients in plants, can solve the problems of easy decomposition or destruction, temperature decomposition influence, instability, etc., and achieve the effect of simple and easy to control and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

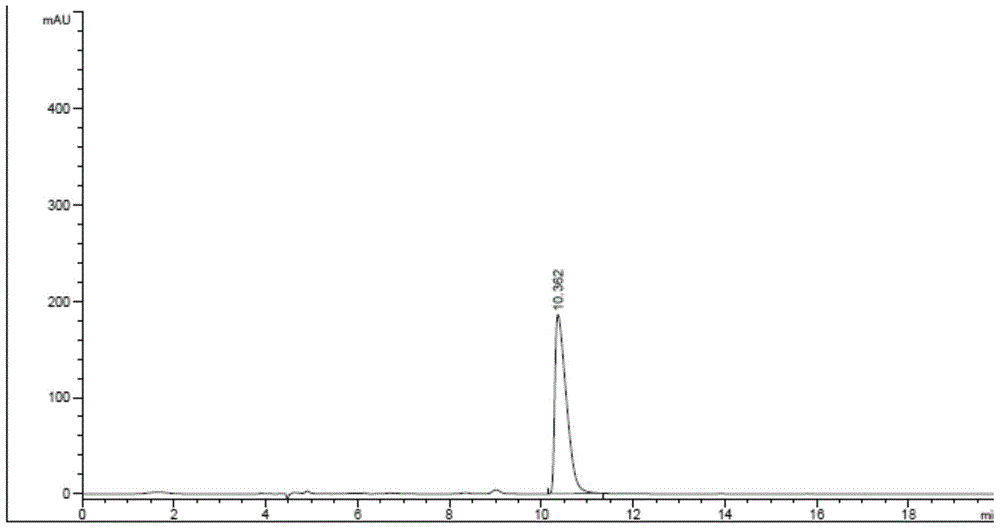

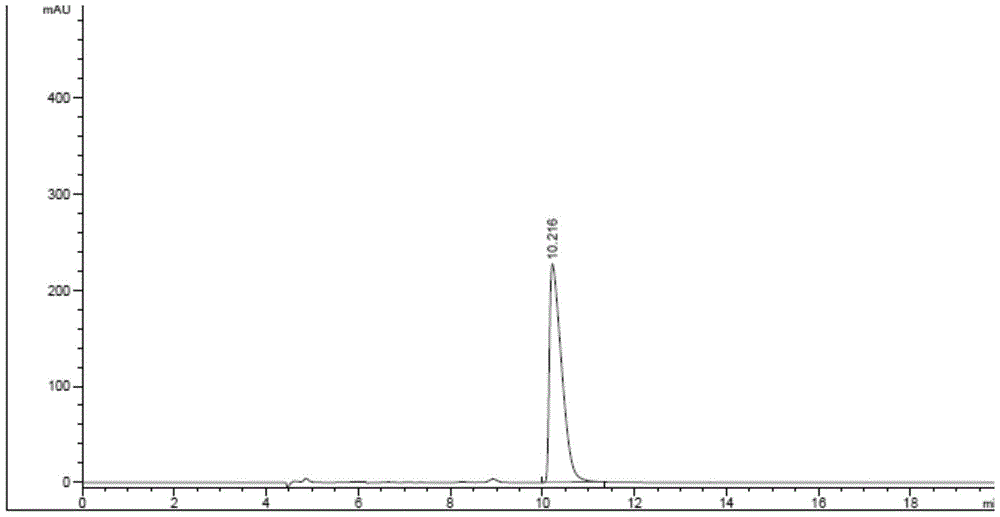

Image

Examples

Embodiment 1

[0019] 1) Take 100kg of dried mustard seeds (the content of sinigrin is 3.3%, HPLC method, the same below), pulverize, reflux extract with 50v / v% ethanol equivalent to 8 times the weight of the raw material for 2h, filter, and reuse the residue Reflux extraction with 10 times the weight of the raw material and 50v / v% ethanol for 1.5h, filter, combine the extracts, extract the obtained extracts under reduced pressure to recover ethanol, centrifuge, and collect the supernatant;

[0020] 2) The supernatant was extracted twice with a mixed solvent (the volume ratio of ethyl acetate to methanol was 5:1), and the organic phase (upper layer solution) was combined and collected, and then the solvent was recovered under reduced pressure to obtain a concentrated solution (6 Baume);

[0021] 3) Take the concentrated solution and apply it to 700B type anion exchange resin column chromatography, wash the resin column with water until the effluent is clear and colorless, then elute with 1.5w...

Embodiment 2

[0042] Example 1 was repeated, except that in step 2), the original mixed solvent (the volume ratio of ethyl acetate to methanol was 5:1) was replaced with a combination of petroleum ether and acetone at a volume ratio of 1:3.

[0043]4.10 kg of sinigrin extract was obtained from this example, and the obtained sinigrin extract was tested, the purity was 72.50%, and the recovery rate of raw material sinigrin was 90.08%.

Embodiment 3

[0045] Example 1 was repeated, except that, in step 3), the anion exchange resin type 700B was replaced with anion exchange resin type 700A.

[0046] 4.05 kg of sinigrin extract was obtained from this example, and the obtained sinigrin extract was tested, and the purity was 73.80%, and the recovery rate of raw material sinigrin was 90.57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com