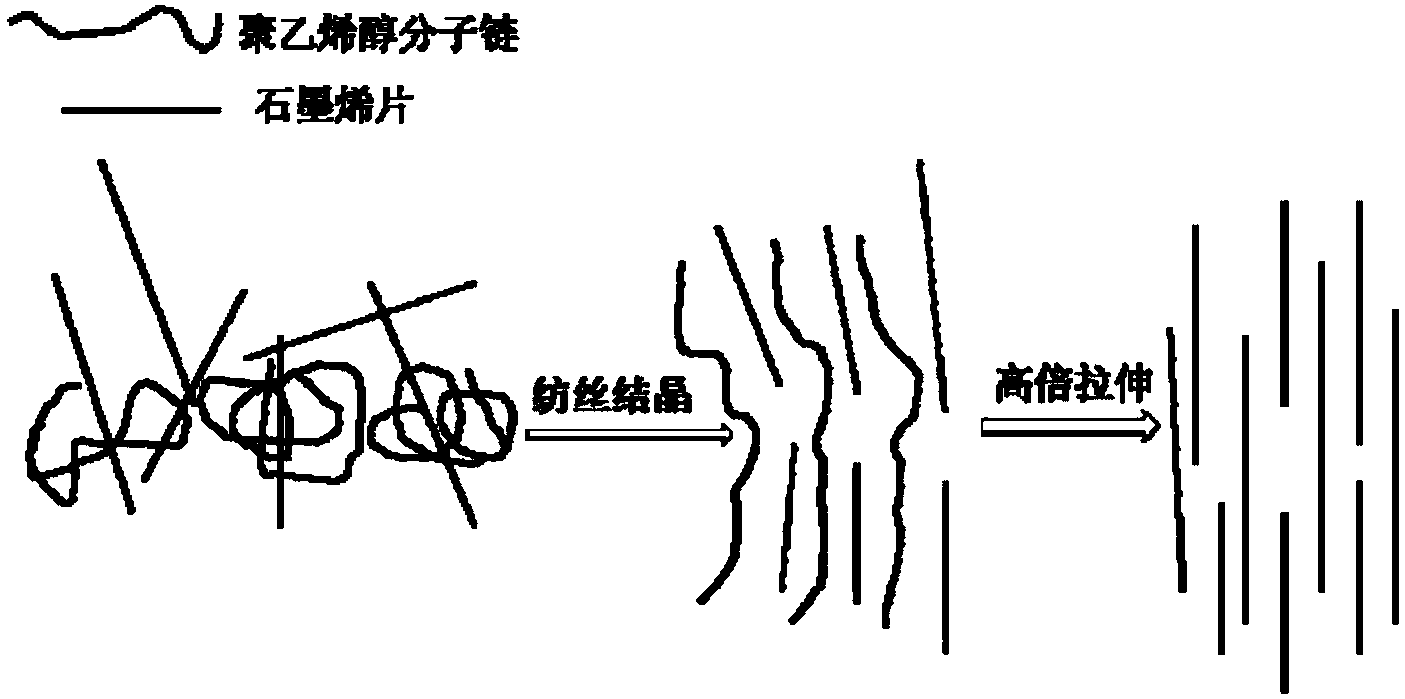

Preparation method of high-strength and high-modulus polyvinyl alcohol-graphene nano composite fibers

A nano-composite fiber, polyvinyl alcohol technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation and other directions, can solve the problems of low price, high specific work at break, good adhesion, etc. The effect of improving crystallinity and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

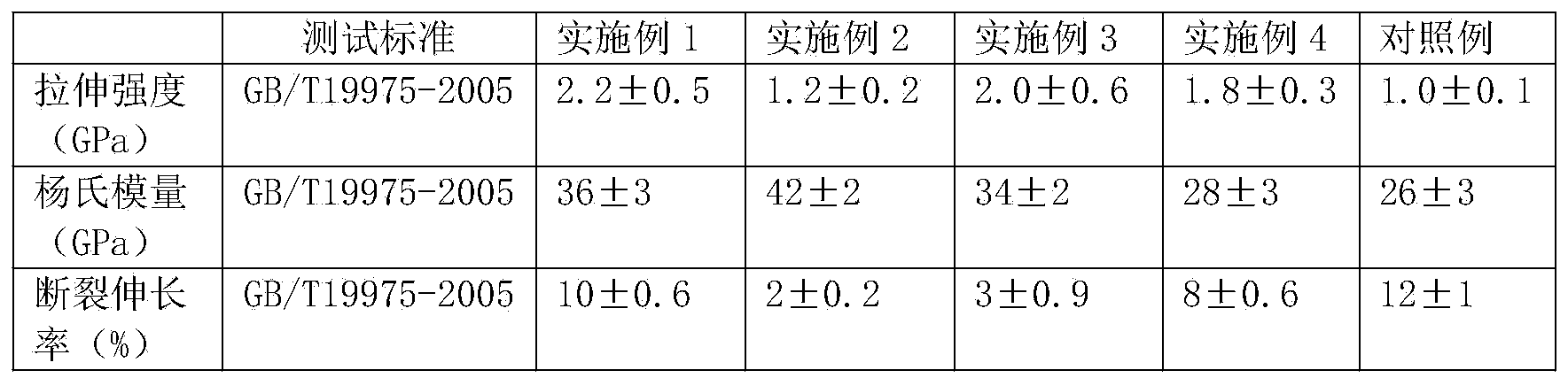

Embodiment 1

[0026] This embodiment relates to a method for preparing high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fibers. After graphene and polyvinyl alcohol are uniformly mixed in a mixed solvent, they are spun by a gel spinning method with high heat Stretching to obtain high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fiber. It includes the following steps:

[0027] (1) Add graphene oxide to a mixed solvent composed of dimethyl sulfoxide and water with a weight ratio of 90:10, ultrasonically disperse for 3 hours, and then add polyvinyl alcohol (polymerization degree 2488±50, alcoholysis degree 95% ), the dissolution temperature is 100°C; the spinning dope is formed. The weight percentage concentration of polyvinyl alcohol in the spinning dope is 15%, and the weight percentage of graphene oxide is 1% of the weight of the polyvinyl alcohol matrix.

[0028] (2) After filtering and vacuum degassing the prepared spinning solution at a temperatu...

Embodiment 2

[0032] This embodiment relates to a method for preparing high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fibers. After graphene and polyvinyl alcohol are uniformly mixed in a mixed solvent, they are spun by a gel spinning method with high heat Stretching to obtain high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fiber. It includes the following steps:

[0033] (1) Add modified graphene to a mixed solvent composed of ethylene glycol and water with a weight ratio of 95:5, ultrasonically disperse for 1 hour, and then add polyvinyl alcohol (polymerization degree 1750±50, alcoholysis degree 80%) , The dissolution temperature is 50°C; the spinning dope is formed. The weight percentage concentration of polyvinyl alcohol in the spinning dope is 10%, and the weight percentage of graphene oxide is 10% of the weight of the polyvinyl alcohol matrix.

[0034] (2) After filtering the prepared spinning dope at a temperature of 80°C and leaving it t...

Embodiment 3

[0038] This embodiment relates to a method for preparing high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fibers. After graphene and polyvinyl alcohol are uniformly mixed in a mixed solvent, they are spun by a gel spinning method with high heat Stretching to obtain high-strength and high-modulus polyvinyl alcohol-graphene nanocomposite fiber. It includes the following steps:

[0039] (1) Add electrochemically stripped graphene to a mixed solvent consisting of tetrahydrofuran, n-butanol and water with a weight ratio of 70:30, ultrasonically disperse for 6 hours, and then add polyvinyl alcohol (polymerization degree 2488±50, alcoholysis degree 95%), the dissolution temperature is 120°C; the spinning dope is formed. The weight percentage concentration of polyvinyl alcohol in the spinning dope is 25%, and the weight percentage of graphene oxide is 0.1% of the weight of the polyvinyl alcohol matrix.

[0040] (2) After filtering and vacuum degassing the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com