Repaglinide-metformin hydrochloride tablet and preparing method thereof

A metformin hydrochloride tablet and specification technology, which is applied in pill delivery, metabolic diseases, sugar-coated pills, etc., can solve the problems of cumbersome preparation process, many excipient ingredients, and high preparation cost, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1, screening of repaglinide-metformin hydrochloride tablet prescription

[0066] In the early trial production process, wet granulation was considered after mixing raw materials and excipients. Because the dissolution rate did not meet the requirements, I often fumbled later. Now repaglinide, meglumine, poloxamer 188, and a small amount of PVPk30 Added together in the form of a solid dispersion aqueous solution binder, its dissolution rate can reach more than 98%, and the related substances are completely qualified.

[0067] Selection of packaging materials

[0068] Repaglinide-Metformin Hydrochloride Tablets are very sensitive to light, high temperature, and high humidity environments, so when selecting inner packaging materials, single-aluminum colored blister packaging is recommended. The biggest advantage of blister packaging is that it is easy to carry, which can reduce the pollution caused by the medicine during carrying and taking, and the blister pac...

Embodiment 2

[0069] Embodiment 2, one of preparation technology of repaglinide-metformin hydrochloride tablet

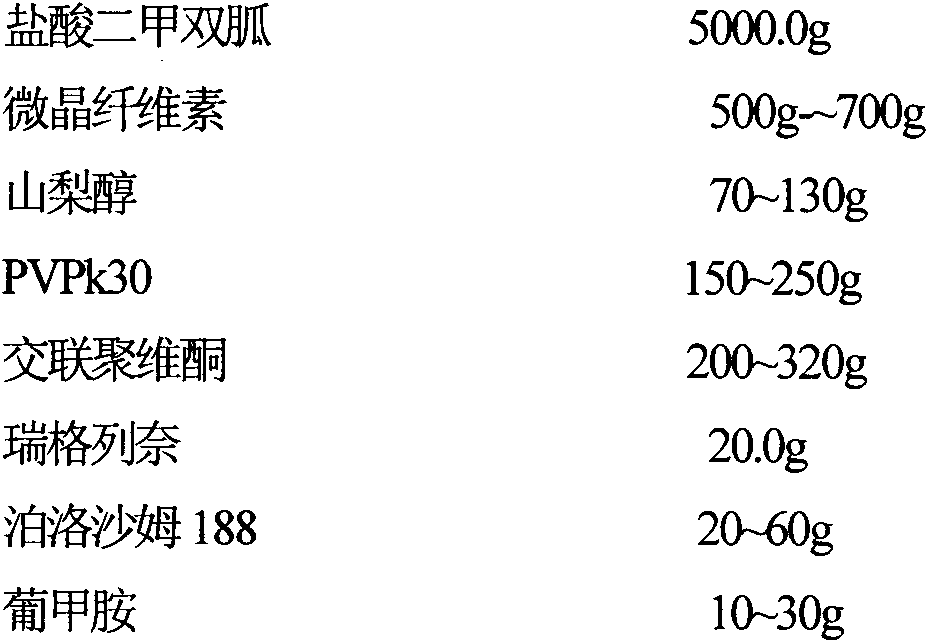

[0070] Each 10,000-tablet specification 500mg / 2mg repaglinide-metformin hydrochloride tablet contains:

[0071]

[0072] The preparation method of the repaglinide-metformin hydrochloride tablet described in the present embodiment comprises the following steps:

[0073] (1) Weigh 5000g of metformin hydrochloride, 620g of microcrystalline cellulose, 100g of sorbitol, 200g of PVPk30, 280g of crospovidone, 20g of repaglinide, 18840g of poloxamer, 20g of meglumine, 305g of PVPk, dioxide Silicon 35g;

[0074] (2) microcrystalline cellulose, sorbitol, crospovidone, and PVPk30 are respectively passed through an 80-mesh sieve, and mixed uniformly;

[0075] (3) Metformin hydrochloride is passed through a 100-mesh sieve, the mixture obtained by step polymerization (2) is diffused in metformin hydrochloride in stages, put into a wet mixing granulator, and stirred for 10 to 20 minutes; ...

Embodiment 3

[0104] Embodiment 3, repaglinide-metformin hydrochloride tablet preparation process two

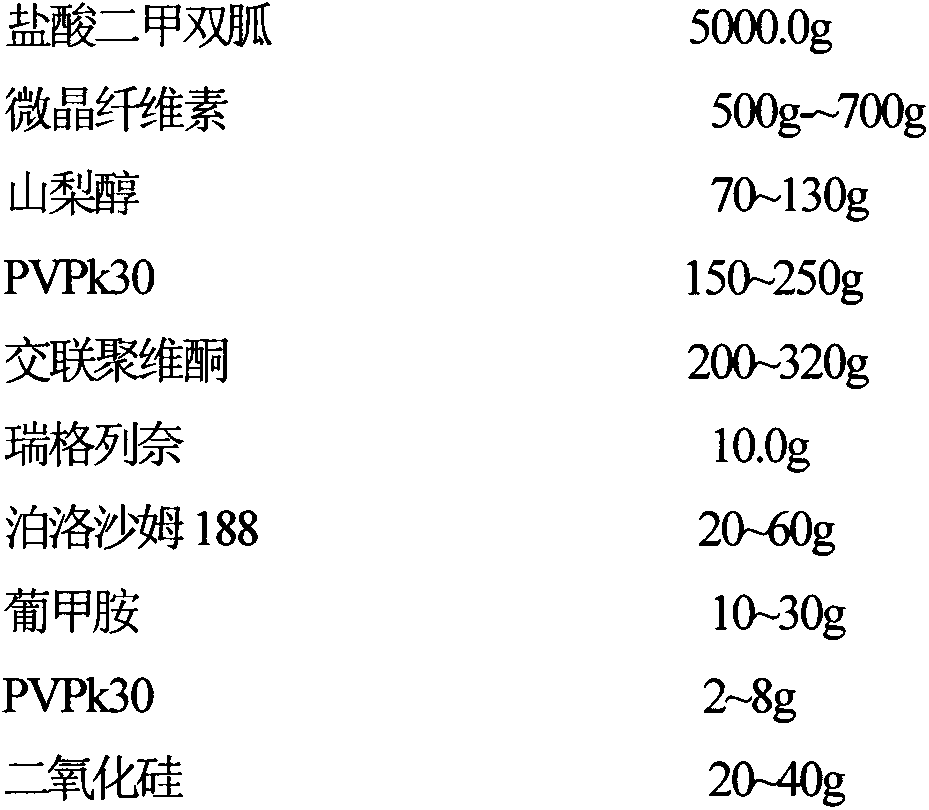

[0105] Each 10,000 tablets of 500mg / 2mg Compound Repaglinide-Metformin Hydrochloride Tablets contains:

[0106]

[0107] The preparation method of the repaglinide-metformin hydrochloride tablet described in the present embodiment comprises the following steps:

[0108] (1) Weigh 5000g of metformin hydrochloride, 620g of microcrystalline cellulose, 100g of sorbitol, 200g of PVPk30, 280g of crospovidone, 20g of repaglinide, 18840g of poloxamer, 20g of meglumine, 305g of PVPk, dioxide Silicon 35g;

[0109] (2) microcrystalline cellulose, sorbitol, crospovidone, and PVPk30 are respectively passed through an 80-mesh sieve, and mixed uniformly;

[0110] (3) Metformin hydrochloride is passed through a 100-mesh sieve, and the mixture obtained by step polymerization (2) is uniformly mixed with metformin hydrochloride in an equal increment method, put into a wet mixing granulator, and stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com