Preparation method of propylene copolymer with low ethylene content and wide molecular weight distribution

A technology of propylene copolymer and propylene, which is applied in the field of preparation of propylene copolymer, and can solve the problems of insufficient molecular weight distribution of polymers, high cost, poor universality of polymerization process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

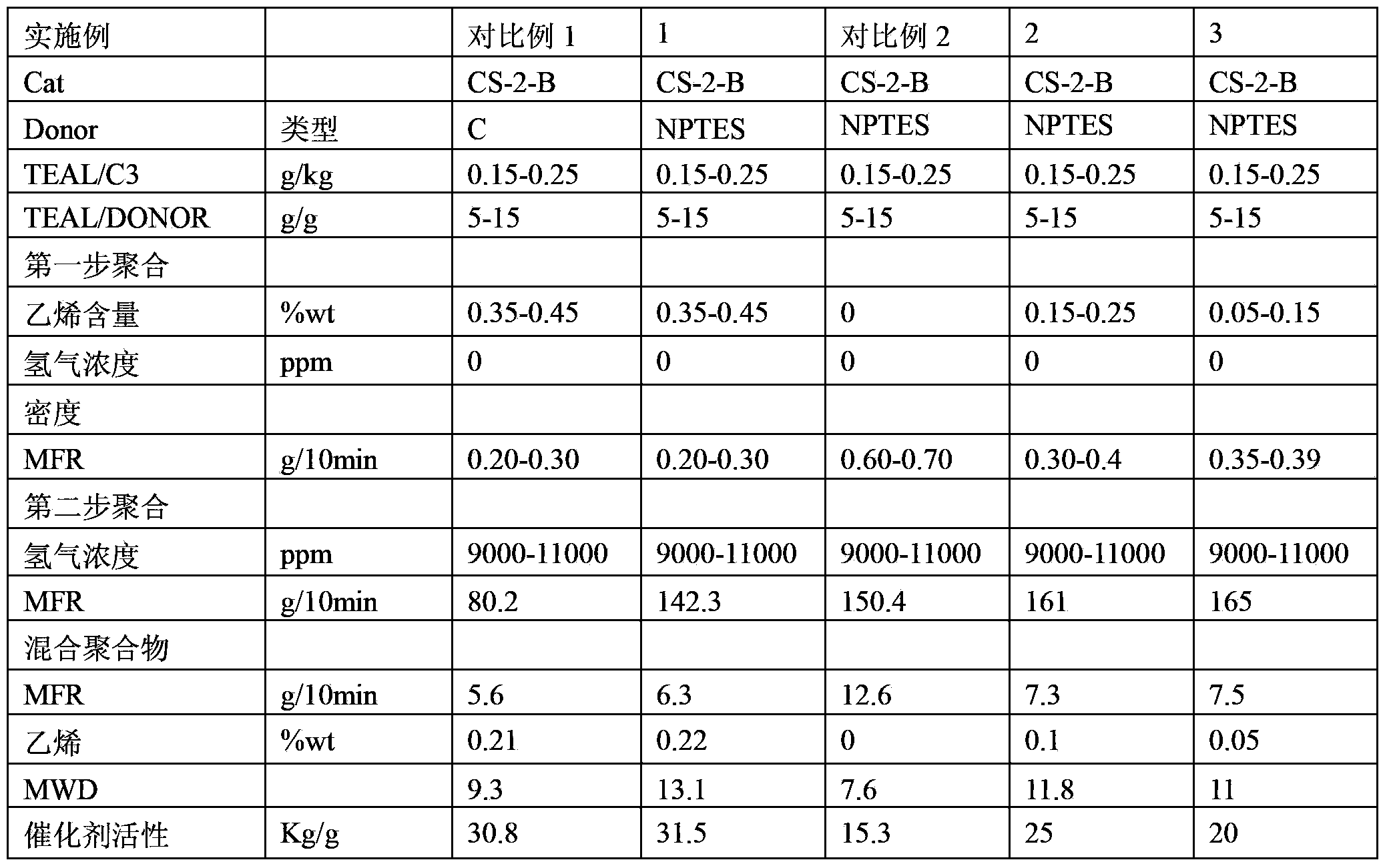

Embodiment 1

[0037]The external electron donor is selected from isopropyltriethoxysilane (NPTES), the first polymer ethylene content is 0.35-0.45% (wt), and the second polymer hydrogen concentration is 9000-11000.

Embodiment 2

[0039] The external electron donor is selected from isopropyltriethoxysilane, the first polymer ethylene content is 0.15-0.25% (wt), and the second polymer hydrogen concentration is 9000-11000.

Embodiment 3

[0041] The external electron donor is selected from isopropyltriethoxysilane, the ethylene content of the first polymer is 0.05-0.15% (wt), and the hydrogen concentration of the second polymer is 9000-11000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com